Light quality and illumination intensity deployment strategy method by utilizing microalga-purified biogas slurry

A technology of light intensity and microalgae, which is applied in the field of environmental engineering, can solve the problems of light inhibition of microalgae growth, influence on the growth of microalgae, influence on lighting effect, etc., and achieves the effect of saving light energy and improving economical practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A new method of adjusting light quality and light intensity using microalgae to purify biogas slurry. It uses biogas slurry and LED lights with specific light quality as nutrient substrate and artificial light source to cultivate microalgae to purify biogas slurry. In this process, through the stepwise light intensity adjustment strategy, the light intensity of LED lights in different growth stages of microalgae is adjusted to achieve the purpose of saving energy and promoting the growth of microalgae to improve the purification effect of biogas slurry.

[0029] The following are the specific steps:

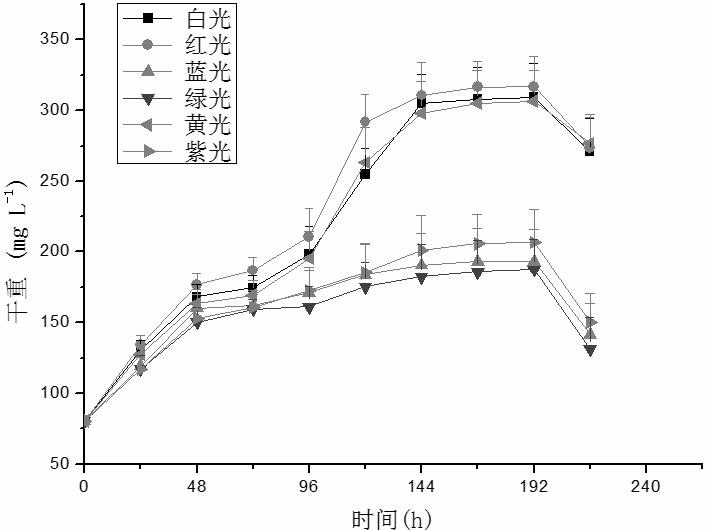

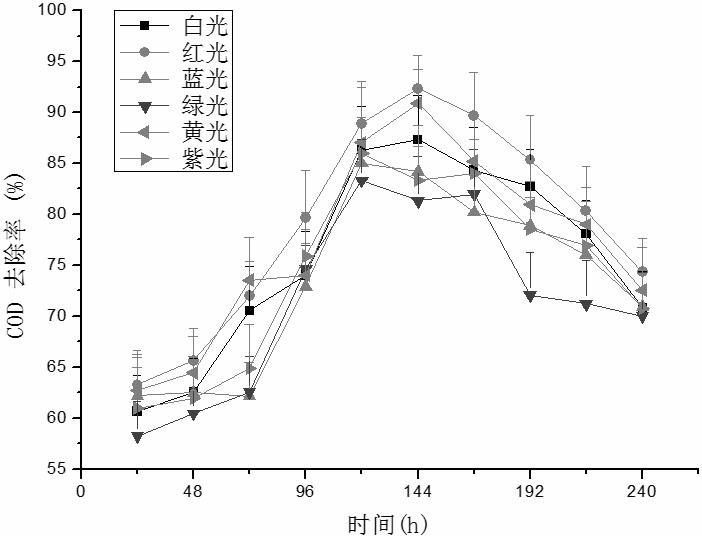

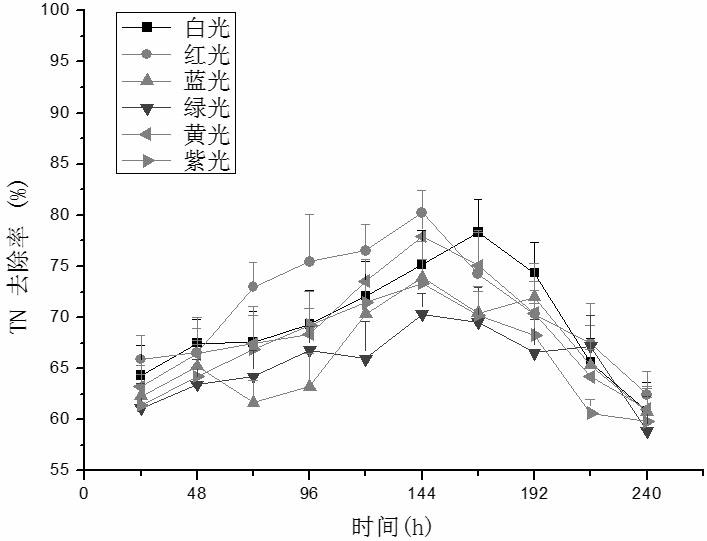

[0030] (1) Set Chlorella ( Chlorella Vulgaris ) under the illumination of white, red, blue, green, yellow and purple LED light sources, with a culture temperature of 25 degrees Celsius, pH=6.5, and a light-to-dark ratio of 12h:12h as conditions, with a light intensity of 2000Lux.

[0031] The results showed that for the proliferation rate of Chlorella at any growth stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com