Supporting roller with roughness keeping capability and manufacturing method thereof

A manufacturing method and back-up roll technology, which is applied in the field of metallurgical roll manufacturing, can solve the problems of rapid roughness attenuation, increase production cost, and reduce production efficiency, and achieve the effects of improving roughness retention, reducing production cost, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the embodiments.

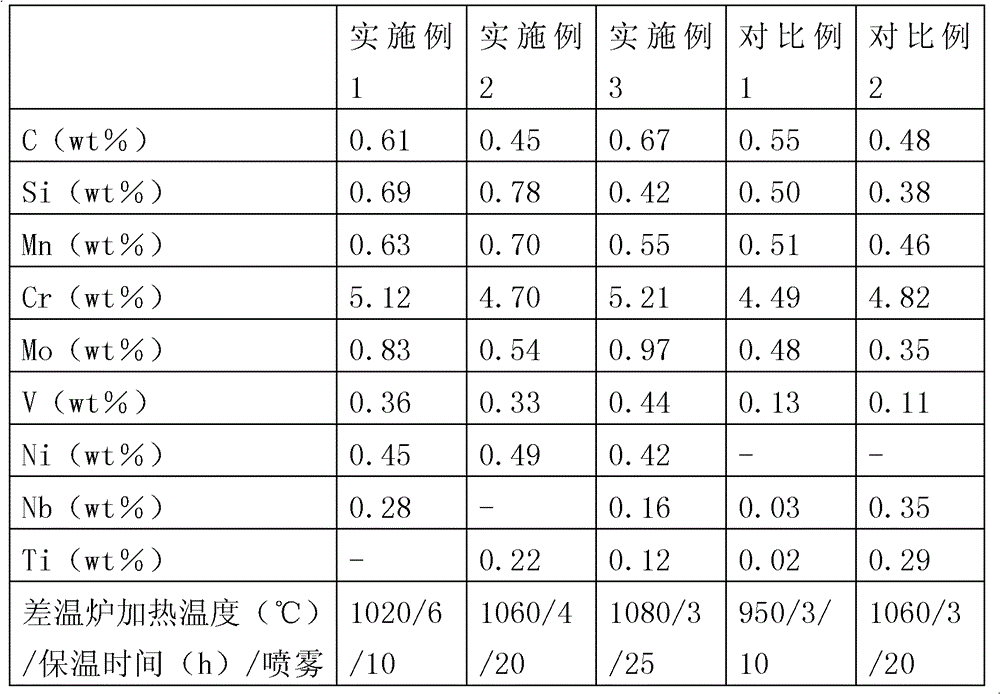

[0033] The process steps of the manufacturing method of each embodiment are basically the same as that of Embodiment 1, and the differences are shown in Table 1.

[0034] Table 1

[0035]

[0036]

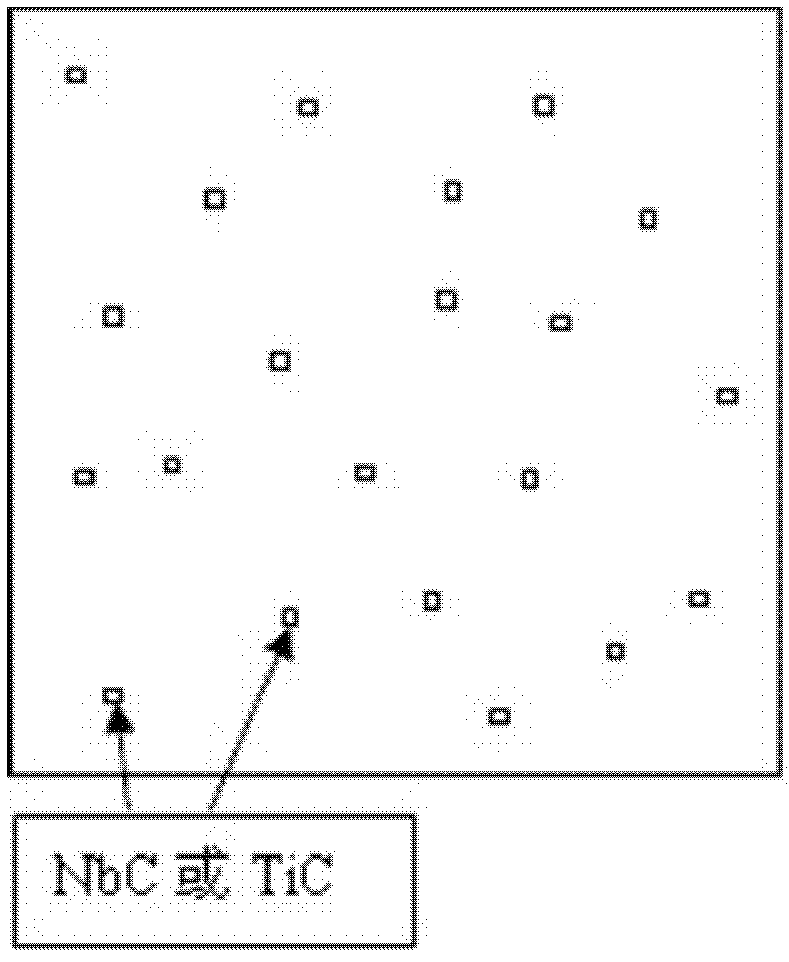

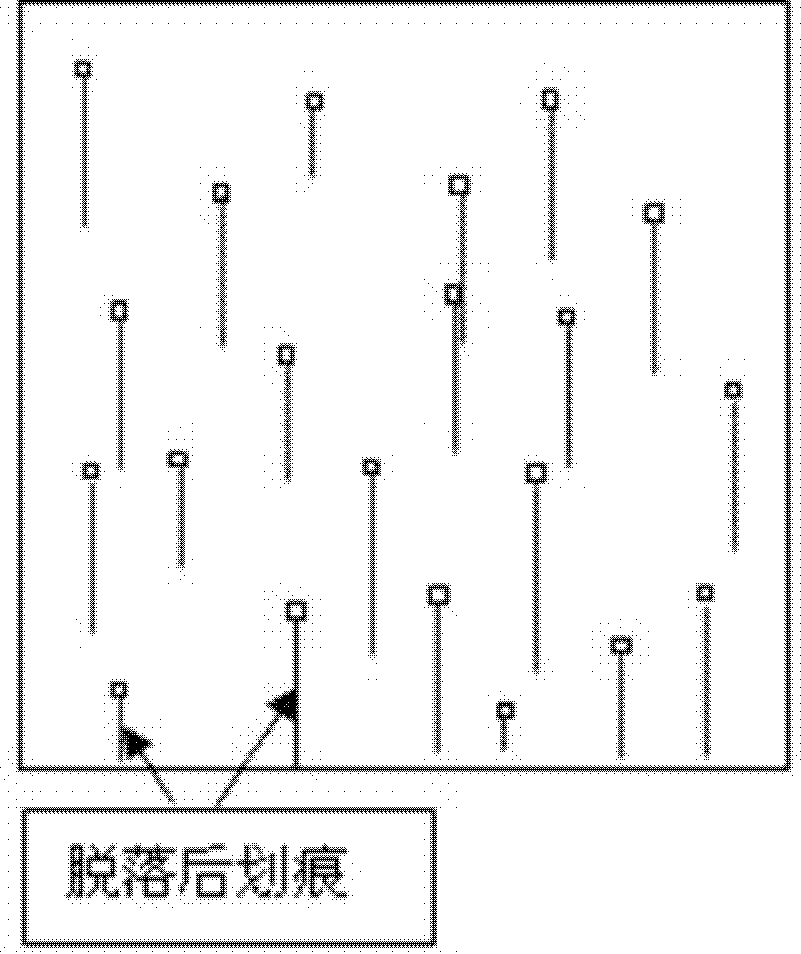

[0037] Due to the high melting point of NbC or TiC carbide particles, they will not melt in the subsequent heat treatment process after they are precipitated from the liquid phase. At the same time, their hardness is also high, and they are easy to fall off during rolling wear, such as figure 1 with figure 2 As shown, friction scratches are formed on the surface of the support roller, so that the surface of the roller can maintain a certain level of roughness.

[0038] According to the material and manufacturing process of this embodiment, a φ1000mm×1420mm physical backing roll was fabricated. The average hardness of the roll surface was 68HSD. A double-ring rolling friction simul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com