Fe-Ti and Fe-Al complex-phase intermetallic compound anti-corrosion layer and preparation method thereof

A technology of intermetallic compounds and corrosion-resistant layers, which is applied in the coating process and coating of metal materials, can solve the problems of general high-temperature corrosion resistance, improve high-temperature corrosion resistance, and solve serious high-temperature corrosion problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

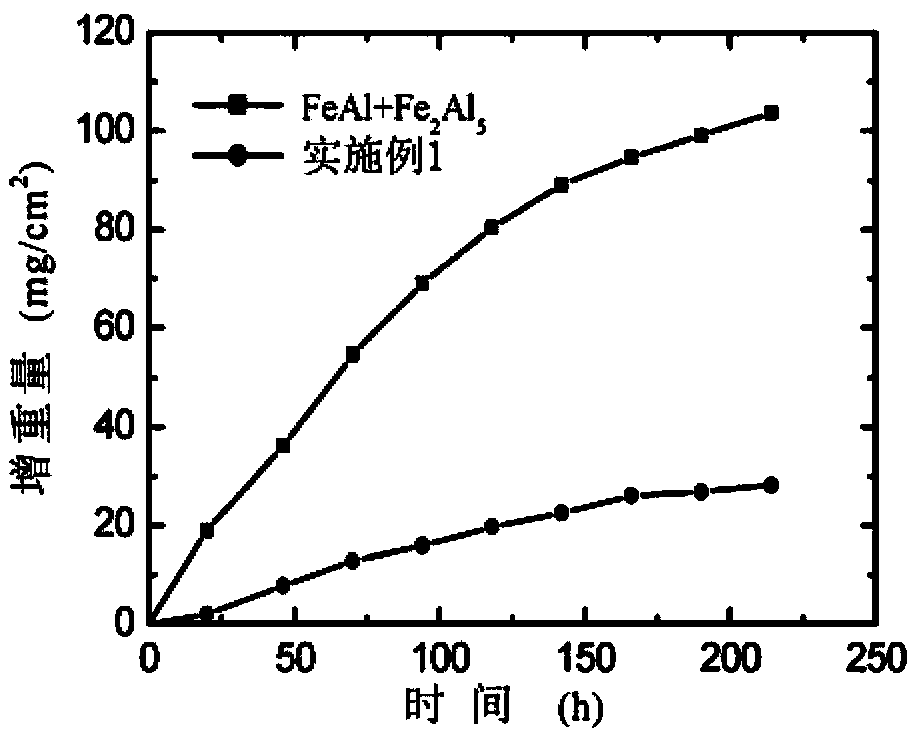

Embodiment 1

[0014] Weigh 5 grams of aluminum powder (100-200 mesh particle size, purity ≥99.5%) and 95 grams of titanium powder (100-200 mesh particle size, purity ≥99.5%), and mix them in a powder mixer for 20 minutes. Prepare the mixed powder into a paste, and apply it on a 20 g pearlitic heat-resistant steel substrate with a geometric size of 100 mm × 200 mm × 3 mm for degreasing and derusting, and control the thickness of the coating layer to about 0.5 mm. After the coating is dried, place it on the cladding workbench. The laser working head connected to the optical fiber is used to move horizontally at a uniform speed and the workpiece is fixed. The titanium-aluminum mixed powder and the pearlite heat-resistant steel matrix are directly synthesized in situ by laser heating to form iron-rich Fe-Ti and Fe-Al. Multi-phase intermetallic compound corrosion resistance layer, the corrosion resistance layer is made of iron-rich Fe 2 Ti and Fe 3 It is composed of Al complex phase intermetal...

Embodiment 2

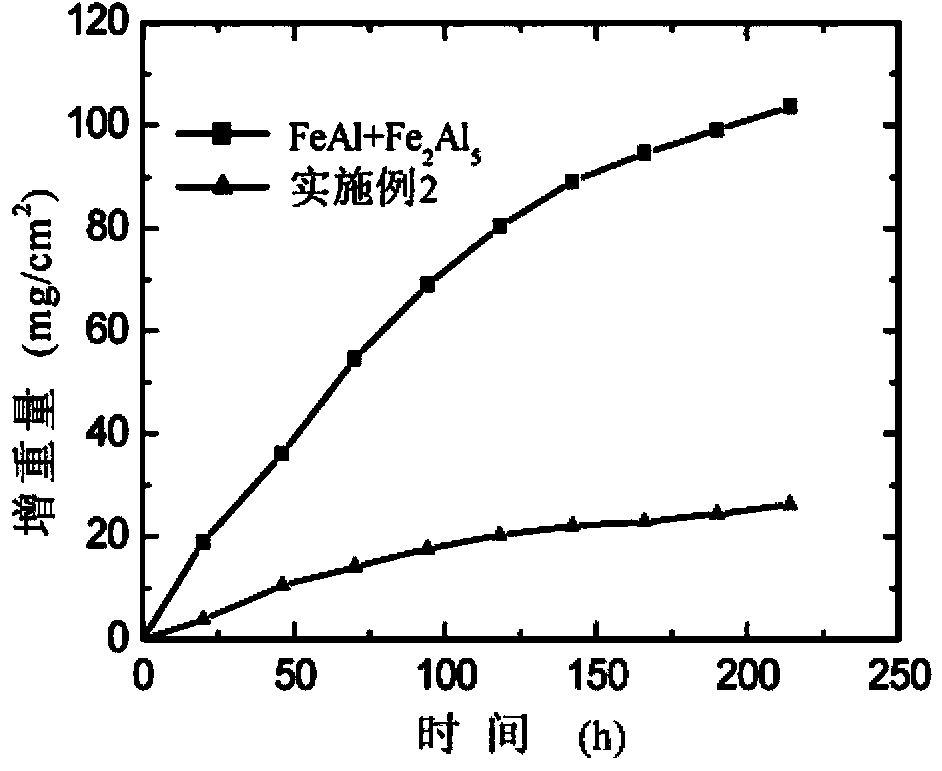

[0016] Weigh 10 grams of aluminum powder (100-200 mesh particle size, purity ≥99.5%) and 90 grams of titanium powder (100-200 mesh particle size, purity ≥99.5%) and mix them in a powder mixer for 20 minutes. Prepare the mixed powder into a paste, and apply it on a 20 g pearlitic heat-resistant steel substrate with a geometric size of 100 mm × 200 mm × 3 mm for degreasing and derusting, and control the thickness of the coating layer to about 0.5 mm. After the coating is dried, place it on the cladding workbench. The laser working head connected to the optical fiber is used to move horizontally at a uniform speed and the workpiece is fixed. The titanium-aluminum mixed powder and the pearlite heat-resistant steel matrix are directly synthesized in situ by laser heating to form iron-rich Fe-Ti and Fe-Al. Multi-phase intermetallic compound corrosion resistance layer, the corrosion resistance layer is made of iron-rich Fe 2 Ti and Fe 3 It is composed of Al complex phase intermetal...

Embodiment 3

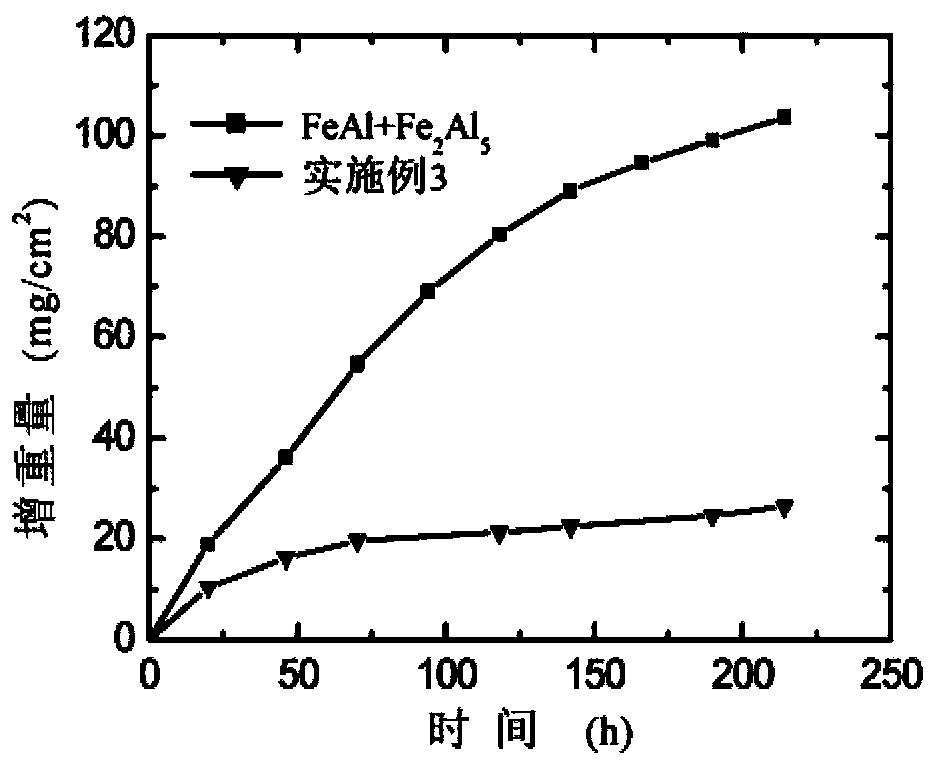

[0018] Weigh 20 grams of aluminum powder (100 mesh to 200 mesh, purity ≥ 99.5%) and 80 grams of titanium powder (100 mesh to 200 mesh, purity ≥ 99.5%), put them into the powder mixer and mix for 20 minutes. Prepare the mixed powder into a paste, and apply it on a 20 g pearlitic heat-resistant steel substrate with a geometric size of 100 mm × 200 mm × 3 mm for degreasing and derusting, and control the thickness of the coating layer to about 0.5 mm. After the layer is dried, place it on the cladding workbench. The laser working head connected to the optical fiber is used to move horizontally at a uniform speed and the workpiece is fixed. The titanium-aluminum mixed powder and the pearlite heat-resistant steel matrix are directly synthesized in situ by laser heating to form iron-rich Fe-Ti and Fe-Al. Multi-phase intermetallic compound corrosion resistance layer, the corrosion resistance layer is made of iron-rich Fe 2 Ti and Fe 3 It is composed of Al complex phase intermetallic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com