Preheater applied to liquid state lead bismuth alloy experimental loop

A liquid lead-bismuth alloy and experimental circuit technology, applied in water heaters, fluid heaters, metal processing equipment, etc., can solve the problems of increased shell tube volume, seal failure, and high filling cost of liquid lead-bismuth alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

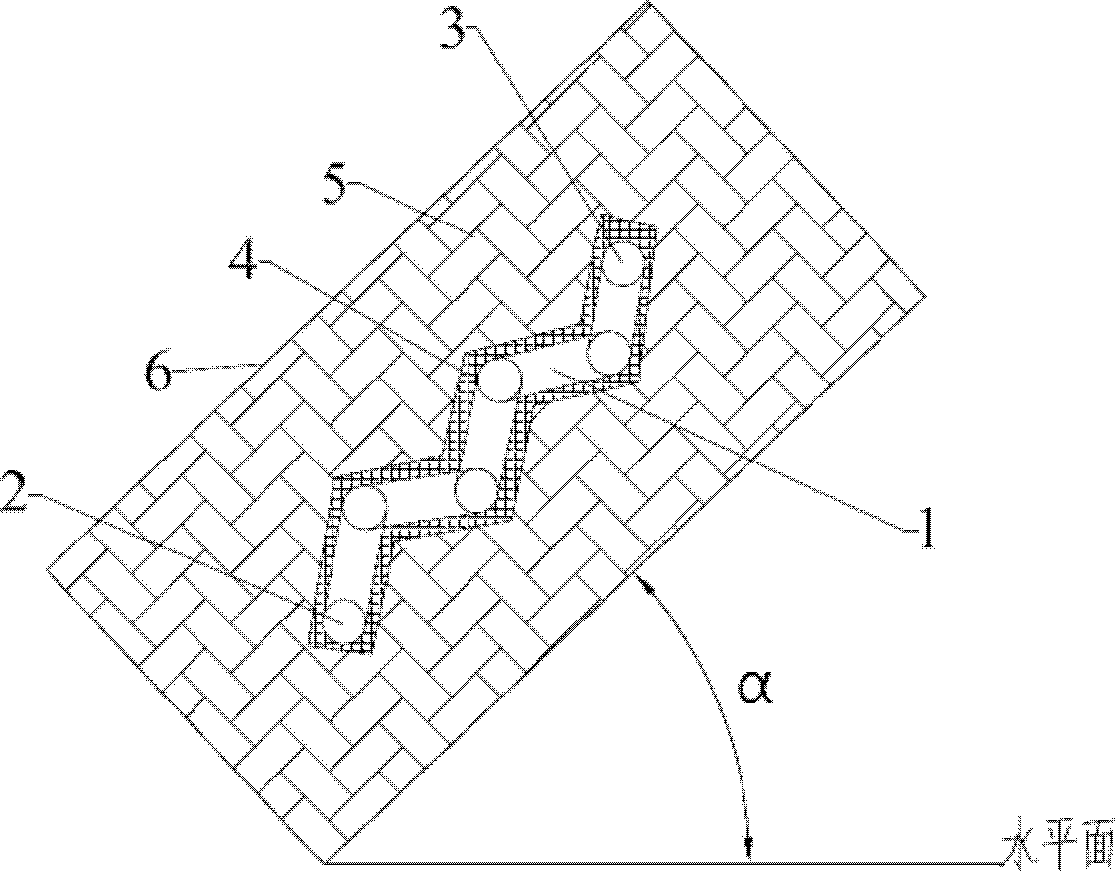

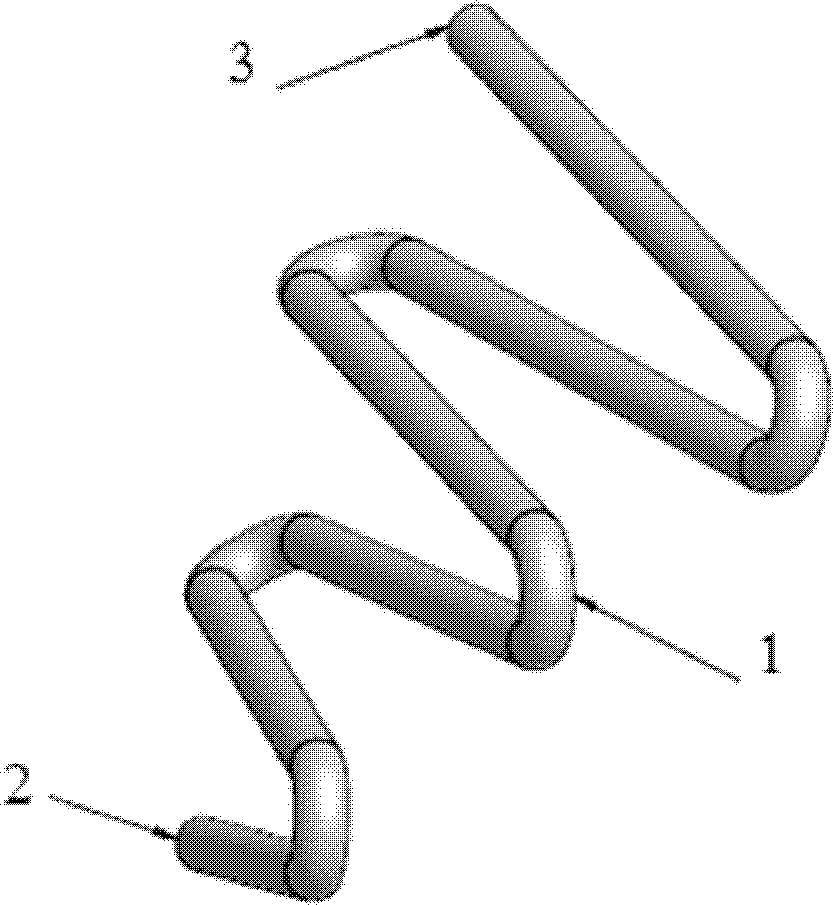

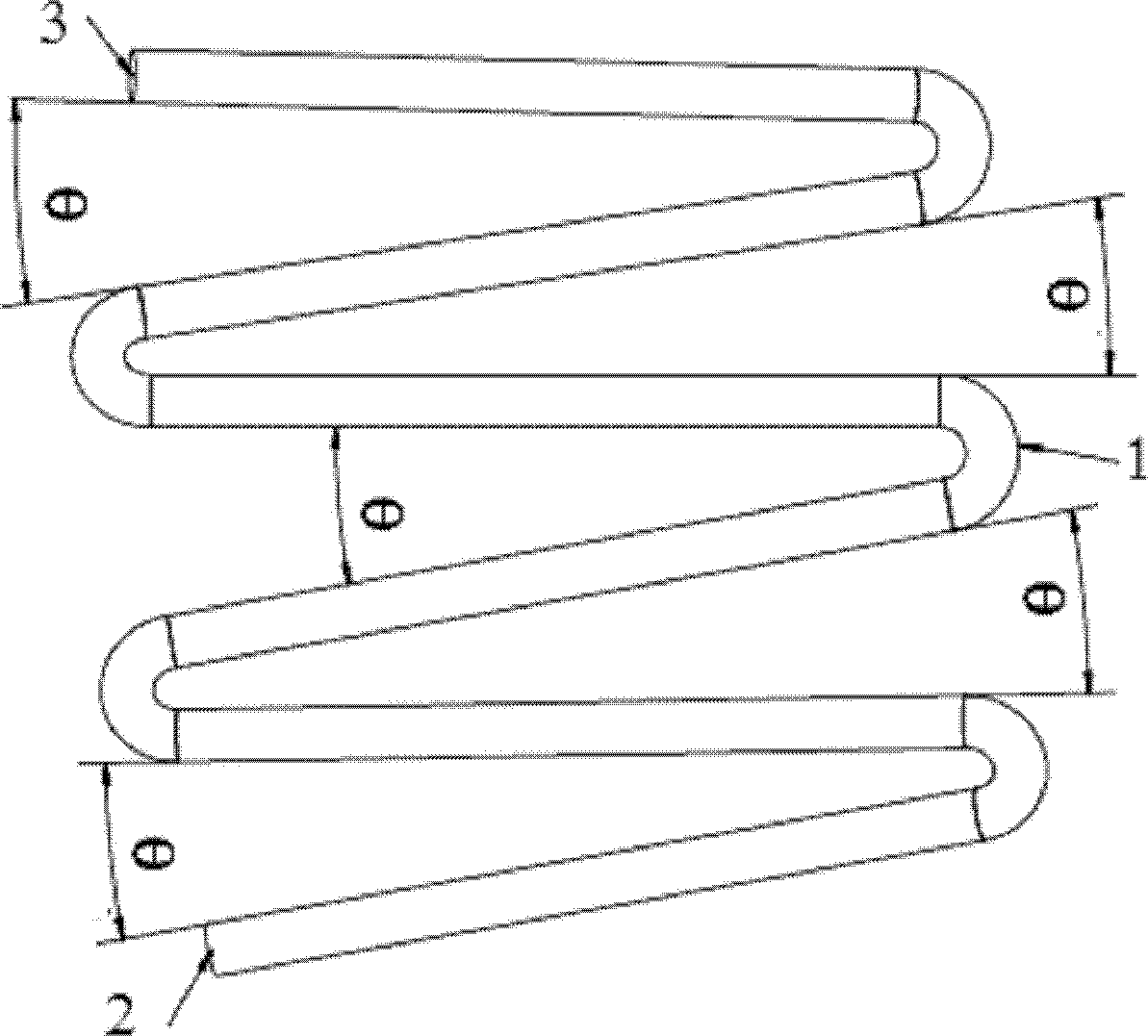

[0032] The preheater used in the liquid lead-bismuth alloy experimental circuit of the present invention comprises: a material pipeline, a material inlet, a material outlet, an electric heating layer, an insulating layer and a metal protective shell. When the preheater of the present invention is installed, the whole preheater is placed at a certain angle with the horizontal plane, the preferred value of the inclination angle α is 5° to 90°, the material inlet is set at a low position, the material outlet is set at a high position, and the material inlet and material The included angle of the projection of the outlet on the horizontal plane can be any angle. The material inlet and outlet are connected to the main pipeline of the experimental circuit by welding, and the material and nominal diameter of the material pipeline are the same as the main pipeline of the experimental circuit.

[0033] In the preheater of the present invention, a temperature sensor is arranged on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com