Two-instrument simultaneous measuring method for increasing leveling precision

A technology of leveling and measuring methods, which is applied in the direction of height/level measuring, instruments, measuring devices, etc., can solve problems such as undetectable, low precision, and slow down the progress of the project, so as to save observation time, improve observation speed, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

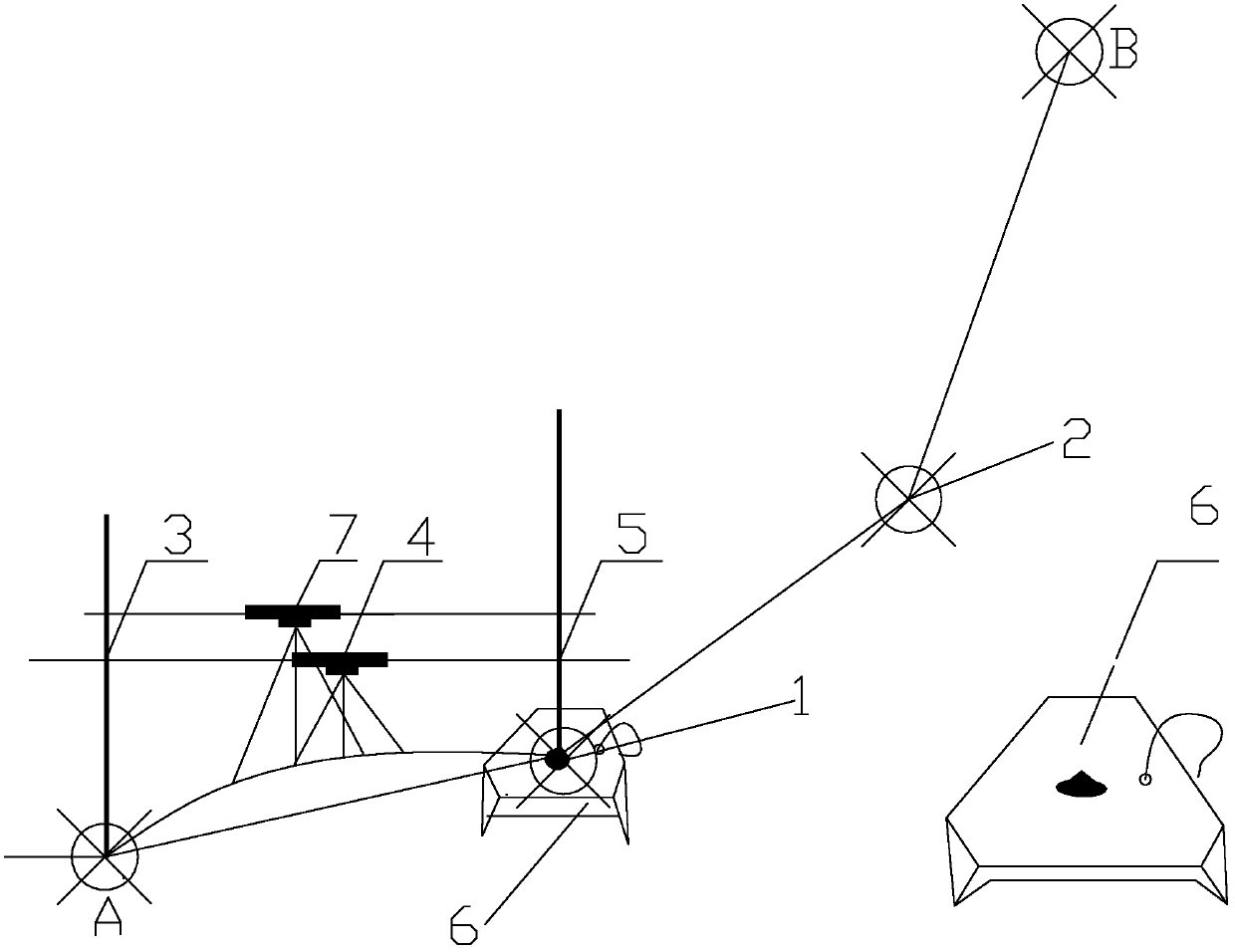

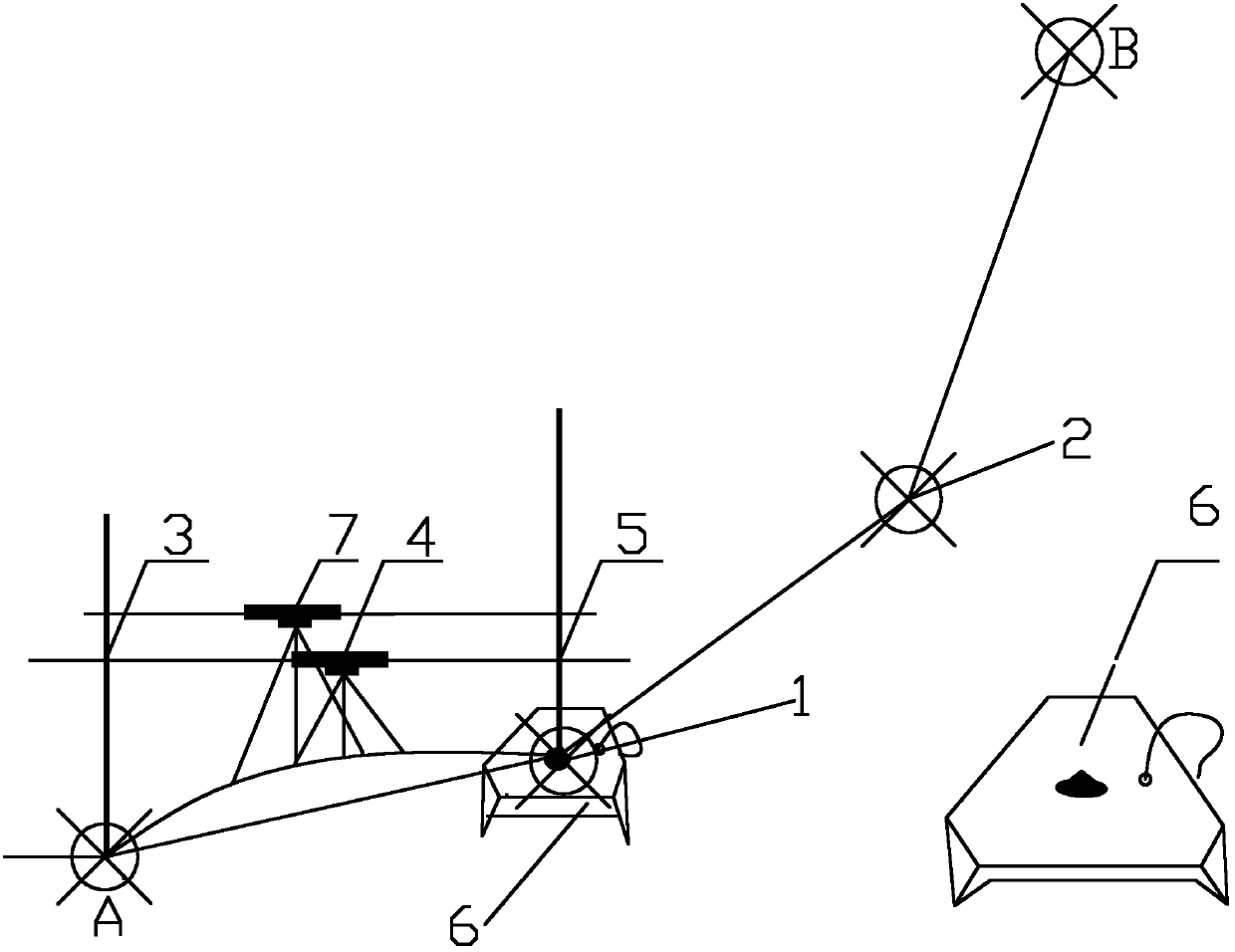

[0022] A simultaneous measurement method for two instruments to improve the leveling accuracy of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0023] A method for simultaneous measurement of two instruments for improving leveling accuracy of the present invention comprises the following steps:

[0024] 1) Select four surveying technicians, two leveling rods, two ruler pads and two leveling instruments. Among the four technicians mentioned: one is a rear-sight ruler, one is a front-sight ruler, and two for the observer.

[0025] 2) Arranging the supporting leveling route. In industrial buildings, the supporting leveling route is generally arranged, that is, from a known elevation level point A as the starting point, along a route to an unknown elevation level point B as the end point, and the known elevation level point A The line connecting point B with unknown elevation level point B is the supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com