Beam-film four-land structured micro-pressure high-overload sensor chip

A sensor chip, high overload technology, applied to the measurement of the property and force of piezoelectric resistance materials, etc., can solve the problems of staying, not being able to adapt to the working environment of the aerospace field, and not being able to meet the precise measurement of the aerospace field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

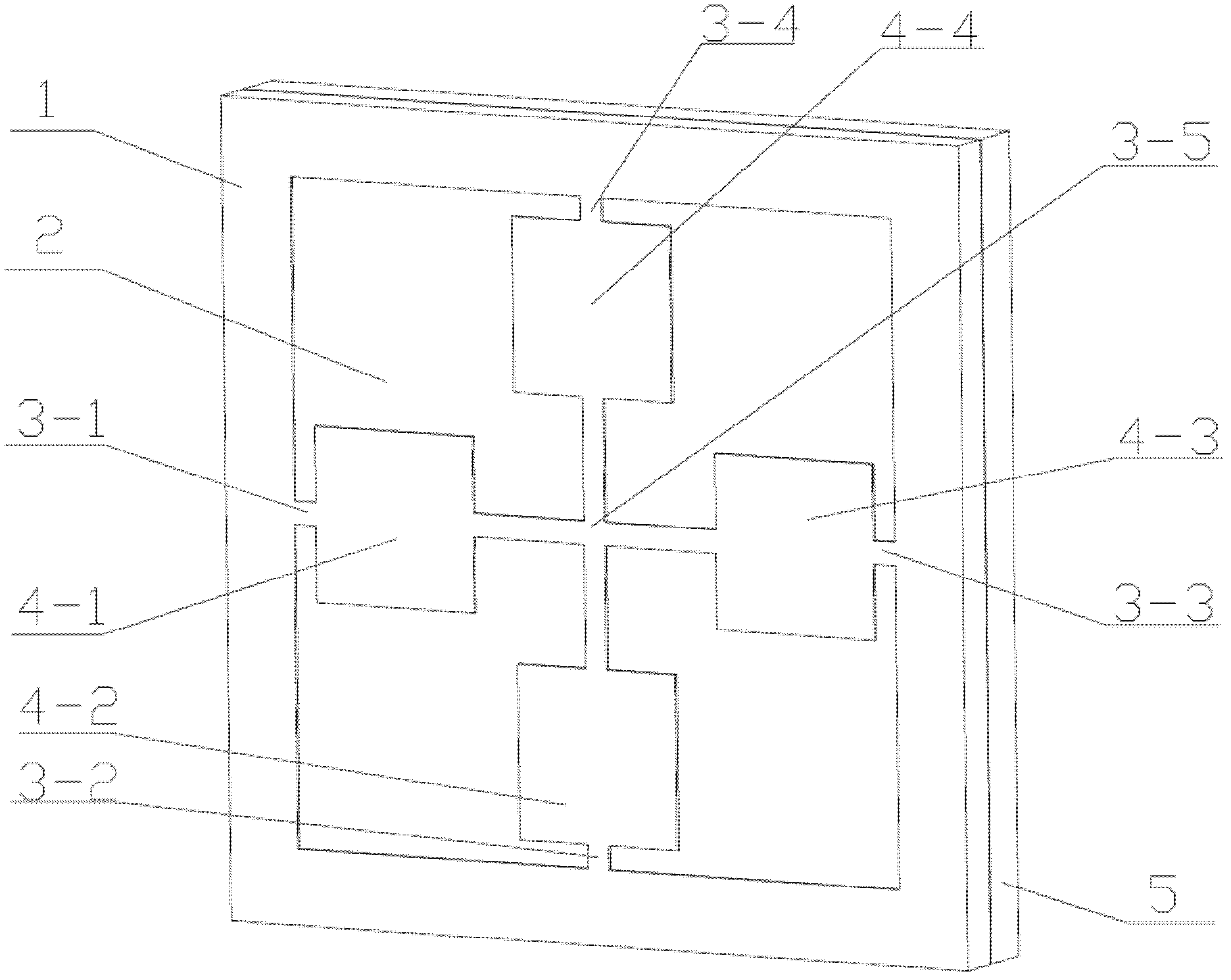

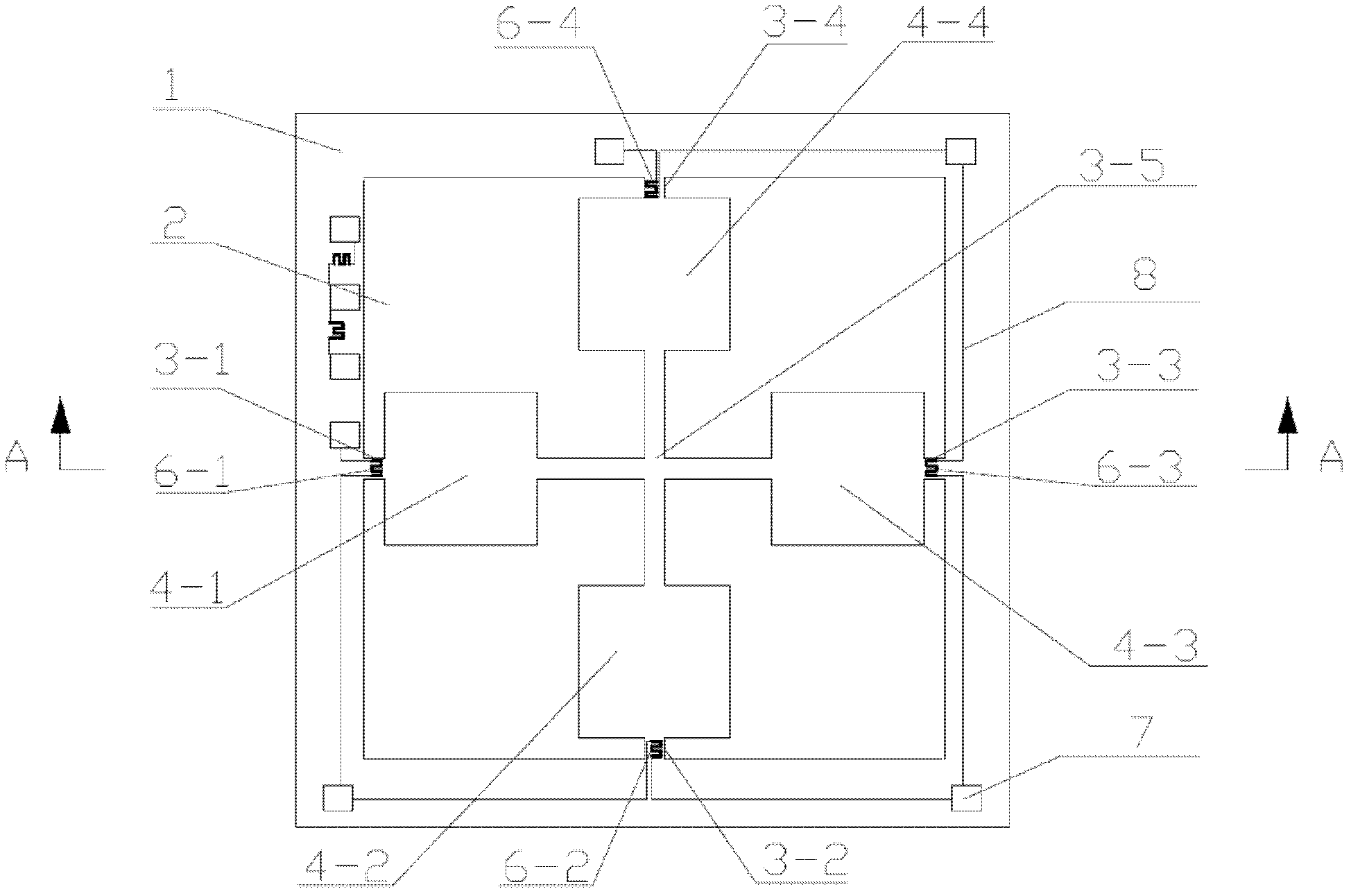

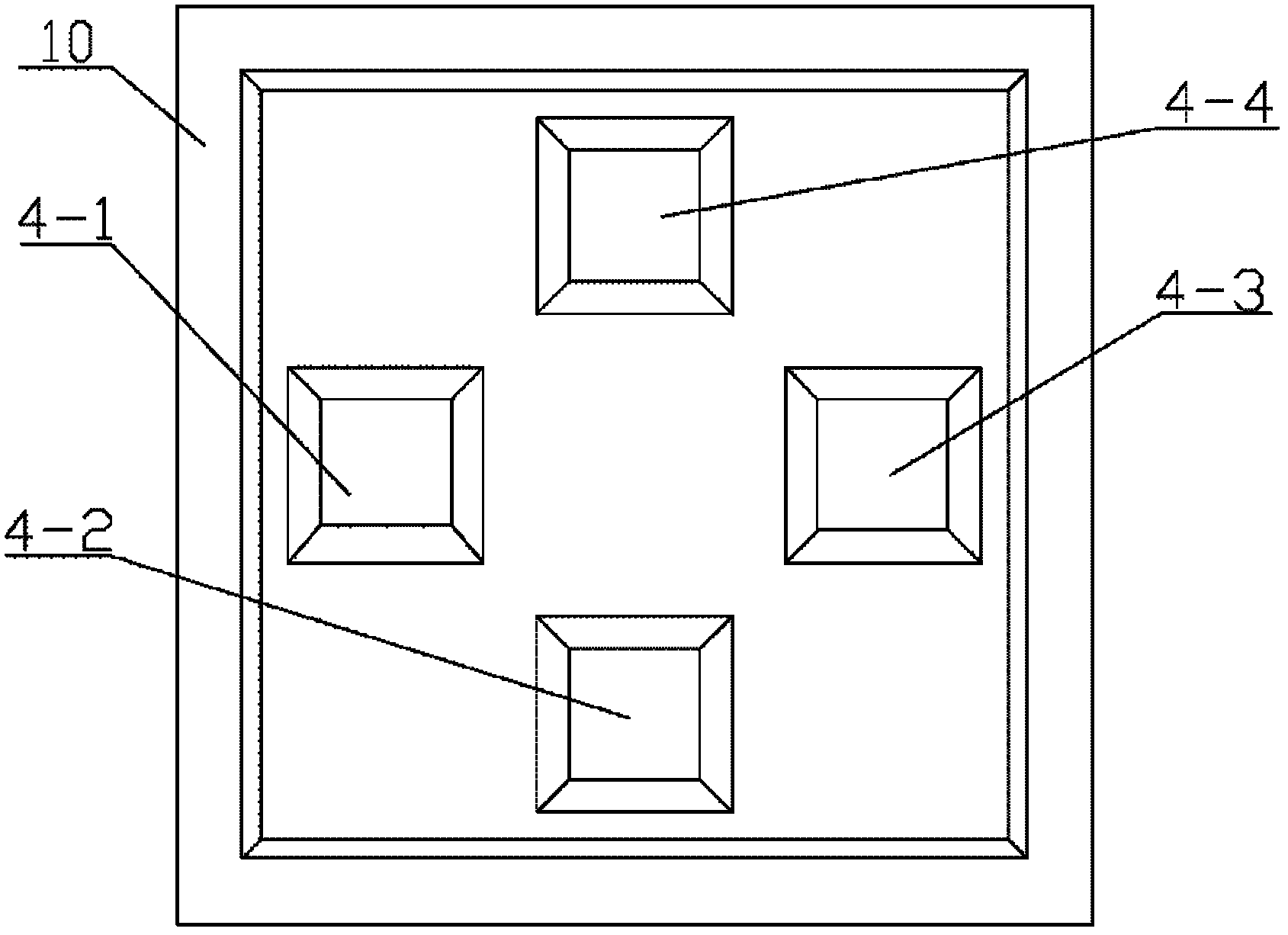

[0022] refer to figure 1 and figure 2 , a beam-membrane four-island structure micro-voltage high-overload sensor chip, including a silicon substrate 1 on which four mass blocks 4-1, 4-2, 4-3, 4-4 and four single beams are processed 3-1, 3-2, 3-3, 3-4 and cross beam 3-5, mass blocks 4-1, 4-2, 4-3, 4-4 pass through four single beams 3-1, 3- 2. 3-3, 3-4 are connected to the silicon base 1, and the mass blocks 4-1, 4-2, 4-3, 4-4 are connected by cross beams 3-5, and the silicon base 1, mass block 4 -1, 4-2, 4-3, 4-4, the space surrounded by four single beams 3-1, 3-2, 3-3, 3-4 and cross beam 3-5 is processed into a 10-30μm film 2. The back of the silicon substrate 1 is bonded to the Pyrex7740 glass 5, refer to image 3 , Figure 4 and Figure 5 , the back of the mass block 4-1, 4-2, 4-3, 4-4 is thinned, so that there is a vacuum between the mass blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com