Simulation test method of ventilation on-way frictional resistance coefficient of curved tunnel

A simulation test and frictional resistance technology, which is applied in aerodynamic tests, machine/structural component testing, measuring devices, etc., can solve problems such as errors, inability to carry out research on frictional resistance coefficients, and results that cannot be effectively confirmed. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] This method takes the small-radius spiral curved tunnel on the Yalu Expressway—Tiezhaizi No. 1 Tunnel as the prototype tunnel to carry out the simulation verification test. The actual wall roughness of the prototype tunnel is 1.12cm, and the actual air volume of the prototype tunnel to be measured is about 24m 3 / s. The similarity ratio of the simulation test is 1:24, and the test air volume after similar conversion is about 1.0m 3 / s; the prototype tunnel curve radius is 600m.

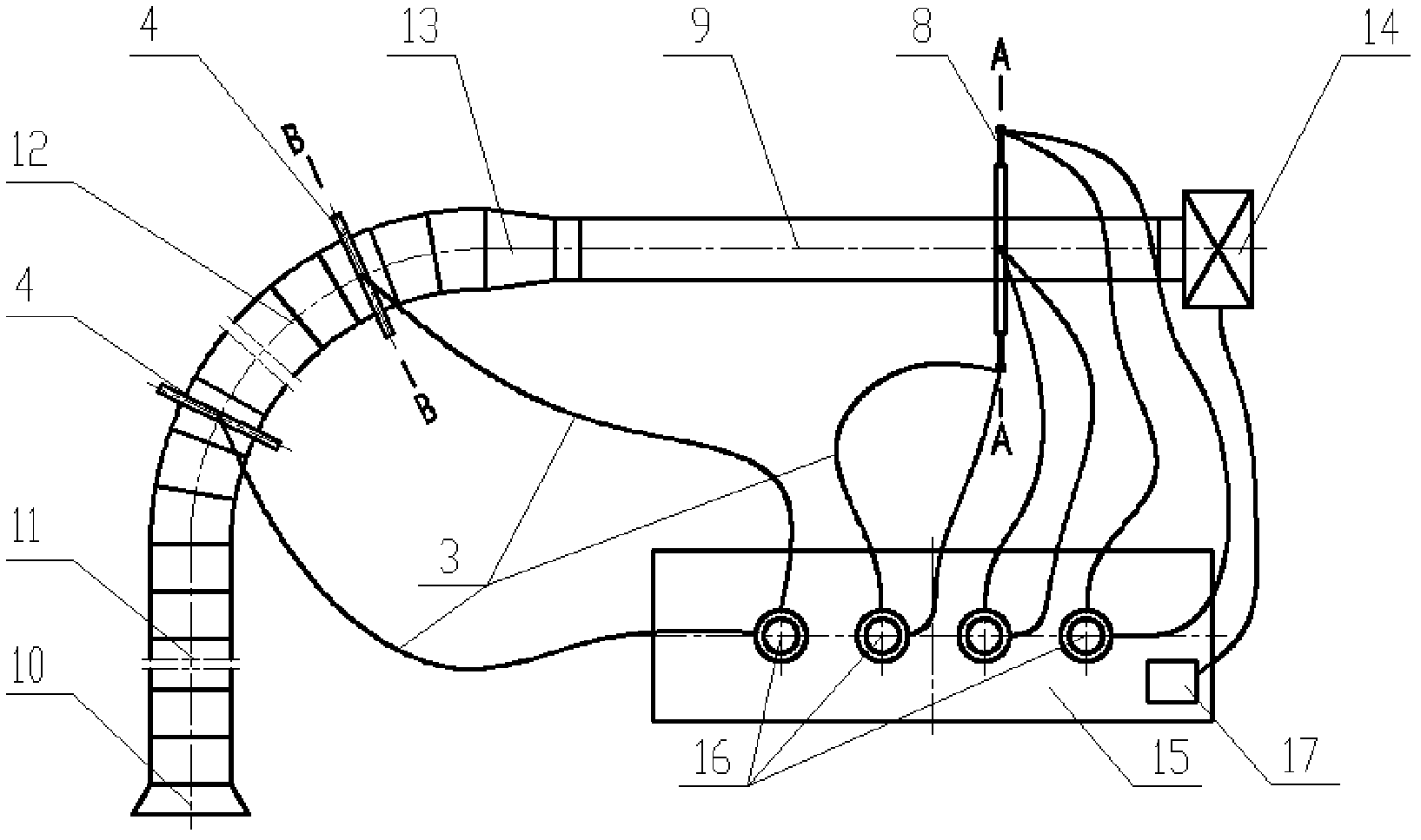

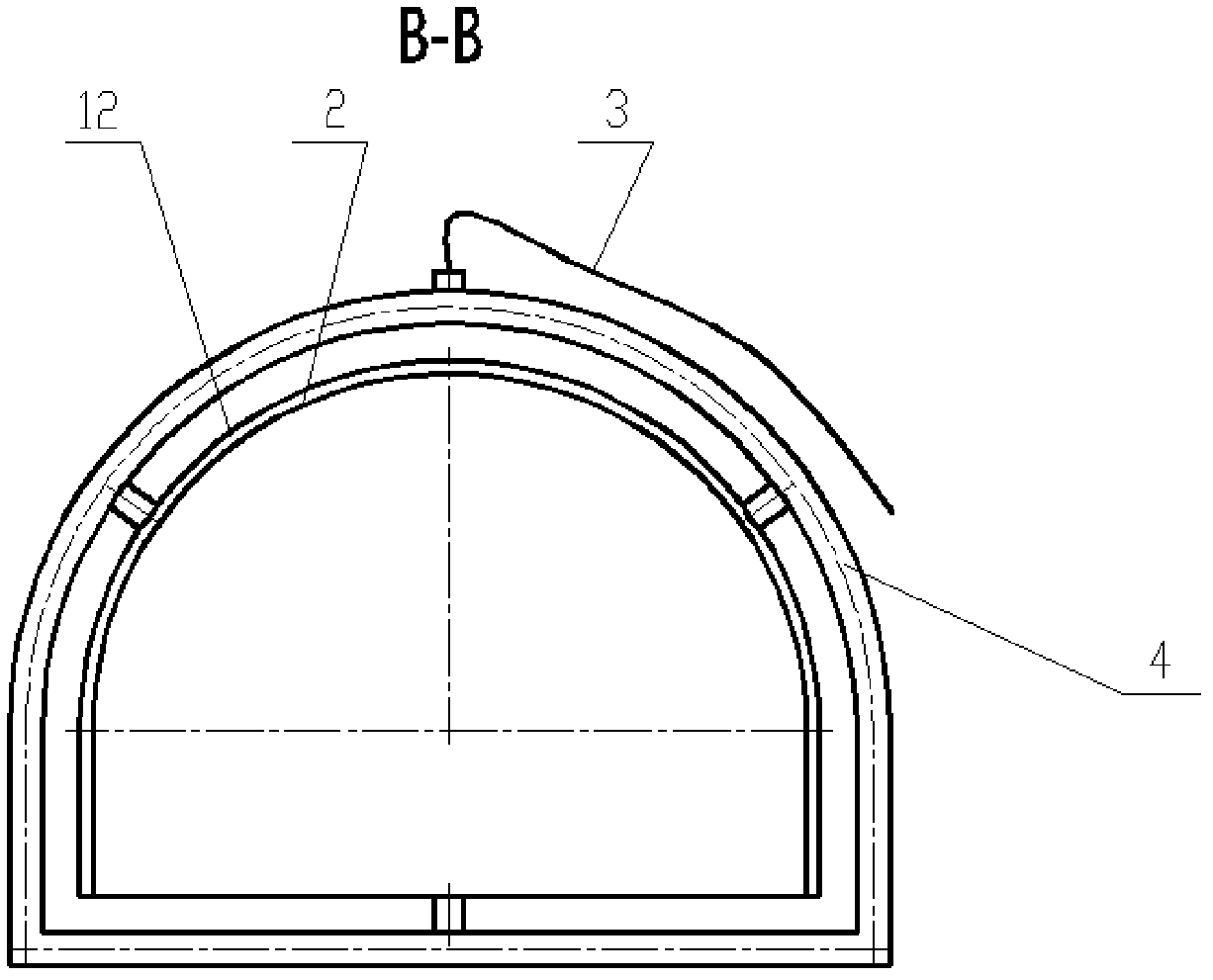

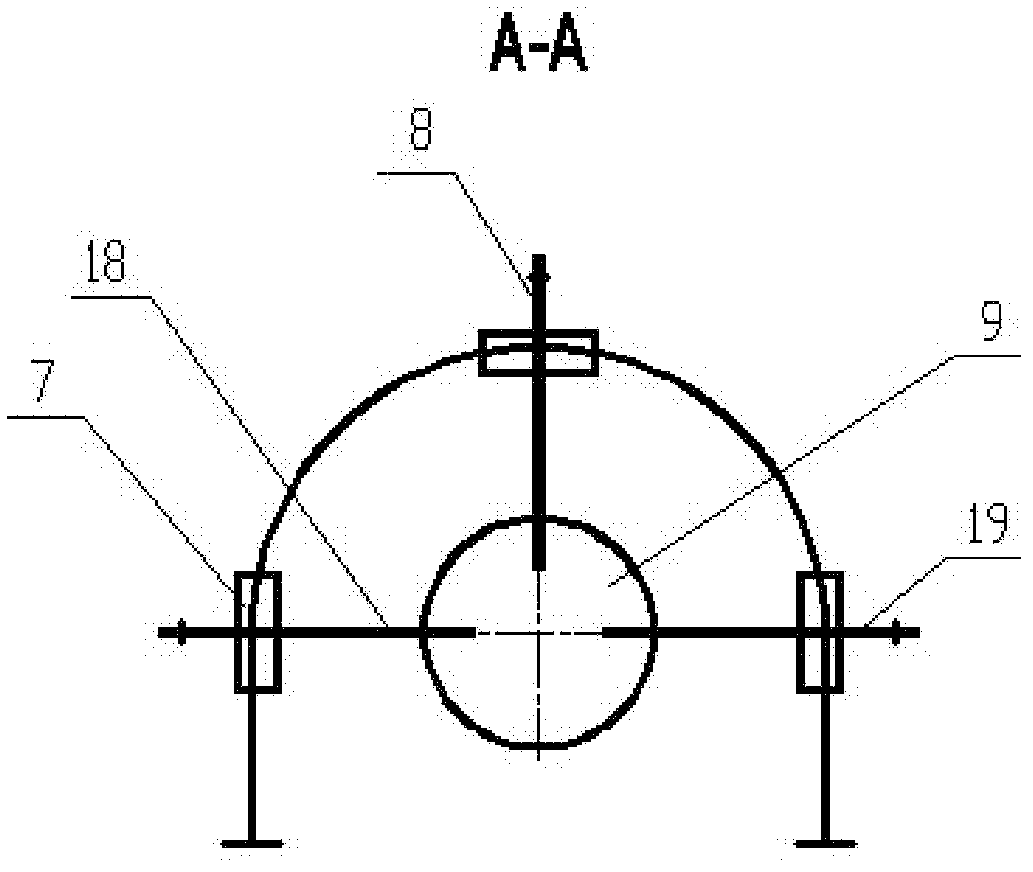

[0022] see Figure 1~3 ,

[0023] 1), according to the similarity ratio, make a curved model tunnel 12 with a section shape similar to the prototype tunnel, a curve radius of 25m, and a connection angle of up to 120° with a material such as glass fiber reinforced plastics according to the axis curve length of 1m. According to the similarity ratio, make a straight line model tunnel 11 with sufficient length for rectification;

[0024] 2) Customize the sandpaper 2 with a roughness of 0.46 mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com