Continuous gas in-tube solid phase microextraction device combined with gas chromatography for use

A technology of gas chromatography and extraction equipment, which is applied in the field of solid phase microextraction sample pretreatment, and can solve the problems of enrichment multiple and selectivity to be further improved, failure to meet the requirements of complete enrichment, low extraction rate of semi-volatile substances, etc. , to achieve the effect of increasing the extraction surface area, easy automation, and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

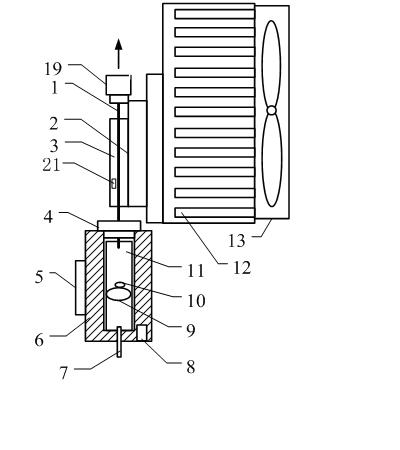

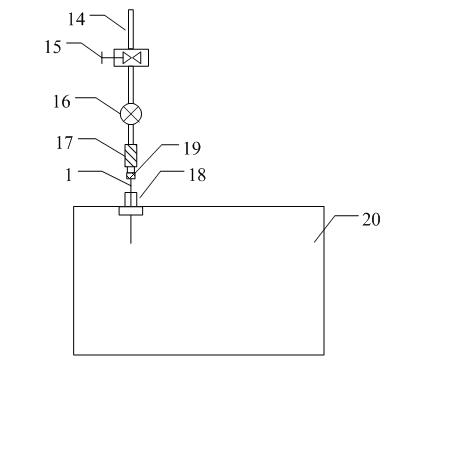

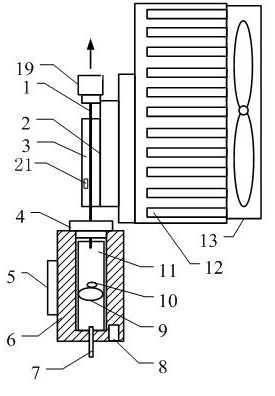

[0018] The continuous gas in-line solid phase microextraction device combined with gas chromatography is composed of two parts: a continuous gas in-line solid phase microextraction device and a sampling device that combines it with gas chromatography. The continuous gas inline solid phase microextraction device is as follows: figure 1 It is composed of solid phase microextraction needle 1 in the tube, a semiconductor condenser, a micro heater, and an inert gas connecting tube 7. The solid phase microextraction needle 1 in the tube is a replacement needle with a metal handle of HAMILTONRN, and the models are N726, N724, and N723 , N722, etc., the needle length is 50mm, and the inner diameter is 0.26-0.41 mm. The inner wall of the injection needle tube is coated with an extraction adsorbent (coating) by an electrochemical method, a sol-gel method or a direct oxidation method. The adsorbent can be an inorganic material adsorbent , organic macromolecules or organic polymers, namely...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com