A method for rapid determination of squalene

A technology for rapid determination and squalene, applied in the field of detection of chemical components in plants, can solve problems such as no relevant literature reports, and achieve the effects of shortening the saponification reaction time, reducing the analysis cost, and improving the detection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

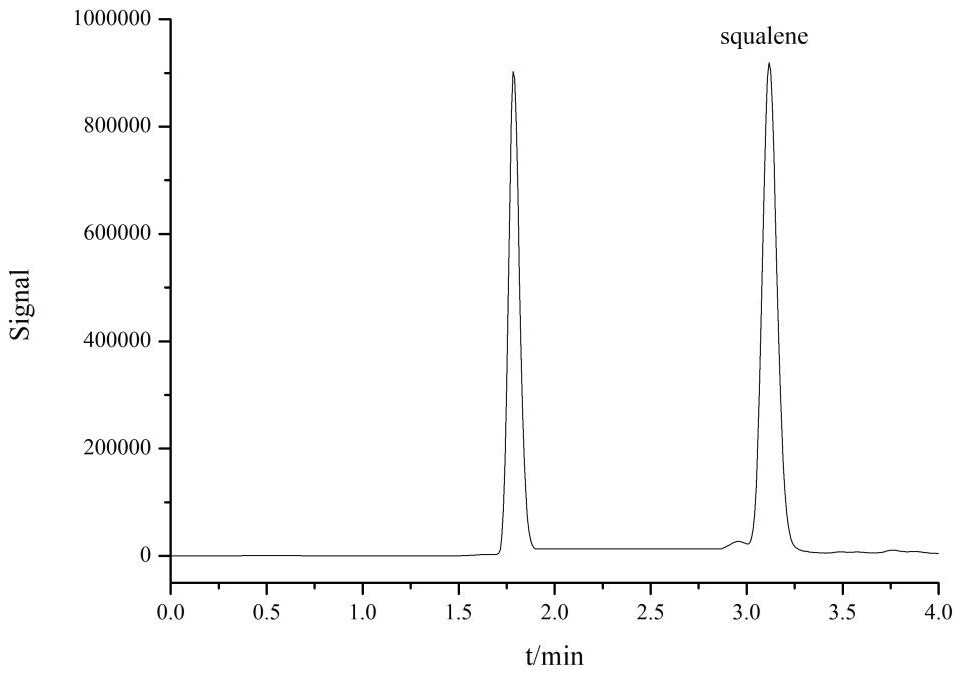

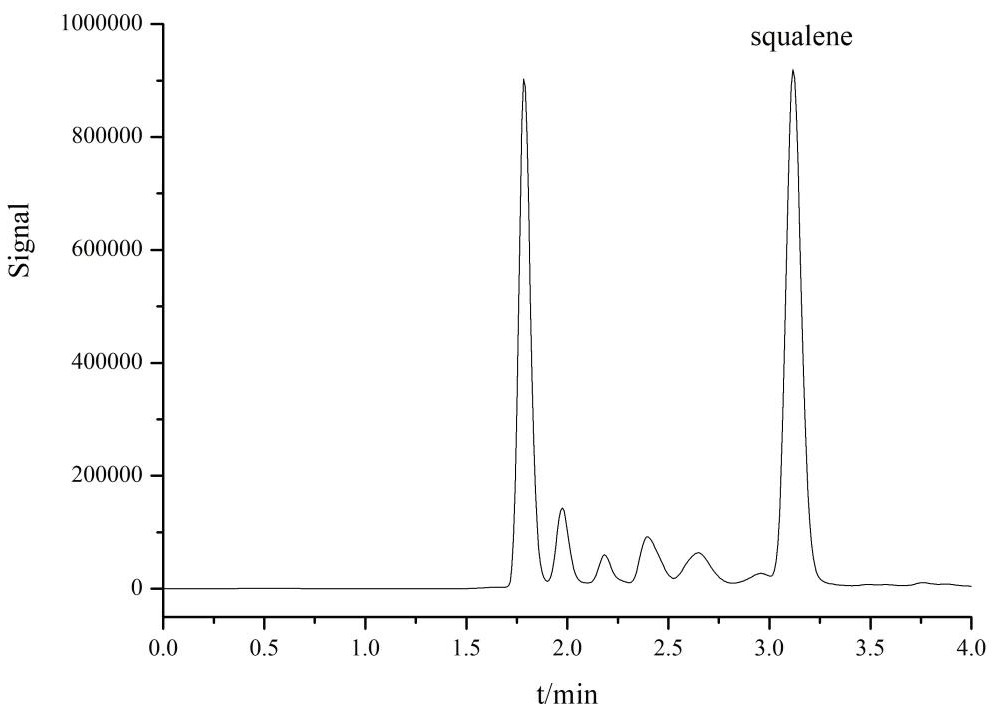

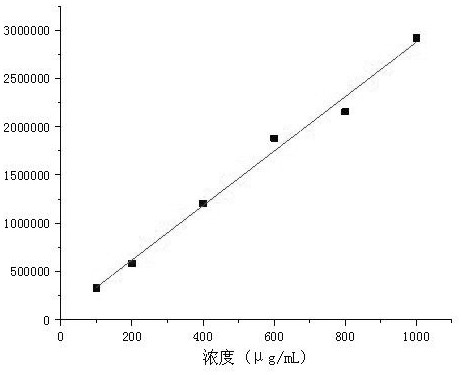

Image

Examples

Embodiment 1

[0035] 1. The preparation of the test solution comprises the following steps:

[0036] A. Take 3g of passion fruit seed powder and place it in an ultrasonic-microwave combined extractor, add 40g of petroleum ether, and then extract under ultrasonic-microwave cooperation. The extraction conditions are ultrasonic power 200W, microwave power 150W, and temperature 35°C , the extraction time is 3 minutes, then the extract is cooled to room temperature, the residue is repeatedly extracted with 40g of petroleum ether after filtration, the extract is combined, and the solvent is evaporated to recover the oil sample;

[0037] B. Take an oil sample and a potassium hydroxide solution with a concentration of 1.0mol / L and place it in an ultrasonic-microwave combined extraction apparatus. The weight ratio of the oil sample to the potassium hydroxide solution is 1:400, and carry out saponification reaction under the cooperation of ultrasonic-microwave For 5 minutes, the saponification reacti...

Embodiment 2

[0050] 1. The preparation of the test solution comprises the following steps:

[0051]A. Take 8g of passion fruit seed powder and place it in an ultrasonic-microwave combined extractor, add 80g of petroleum ether, and then extract under ultrasonic-microwave cooperation. The extraction conditions are ultrasonic power 300W, microwave power 250W, and temperature 45°C , the extraction time was 10 minutes, then the extract was cooled to room temperature, the residue was repeatedly extracted with 80 g of petroleum ether after filtration, the extract was combined, and the solvent was evaporated and recovered to obtain an oil sample;

[0052] B. Take an oil sample and a potassium hydroxide solution with a concentration of 1.0mol / L and place it in an ultrasonic-microwave combined extraction apparatus. The weight ratio of the oil sample to the potassium hydroxide solution is 5:400, and carry out saponification reaction under the cooperation of ultrasonic-microwave For 30 minutes, the sa...

Embodiment 3

[0065] 1. The preparation of the test solution comprises the following steps:

[0066] A. Take 5g of passion fruit seed powder and place it in an ultrasonic-microwave combined extractor, add 65g of petroleum ether, and then extract under ultrasonic-microwave cooperation. The extraction conditions are ultrasonic power 250W, microwave power 200W, and temperature 40°C , the extraction time was 5 minutes, then the extract was cooled to room temperature, the residue was repeatedly extracted with 70 g of petroleum ether after filtration, the extract was combined, and the solvent was evaporated and recovered to obtain an oil sample;

[0067] B. Take an oil sample and a potassium hydroxide solution with a concentration of 1.0mol / L and place it in an ultrasonic-microwave combined extraction apparatus. The weight ratio of the oil sample to the potassium hydroxide solution is 3:400, and carry out saponification reaction under the cooperation of ultrasonic-microwave For 10 minutes, the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com