Method for determining Cembrane diterpene alcoholate in tobacco and tobacco product by gas chromatography-mass spectrometry

A technology of Chinese cedarane diterpene alcohol and tobacco products, which is applied in the field of cetahane diterpene alcohol, can solve problems such as the difficulty of accurate quantitative analysis, the inability to achieve separation, and the difficulty in realizing accurate quantification of derivatization conditions, achieving high extraction efficiency , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

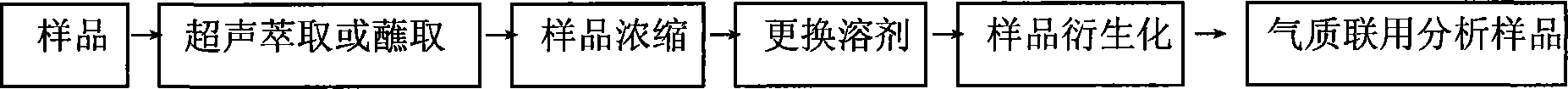

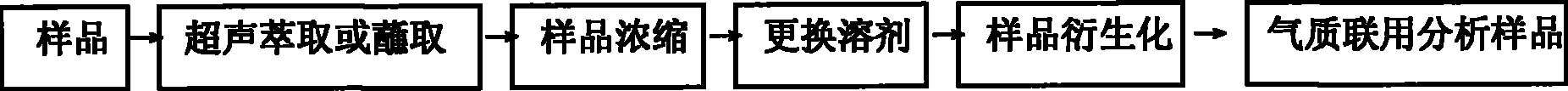

Method used

Image

Examples

Embodiment 1

[0021] a, take by weighing 0.2-0.5g of the tobacco sample of 40 mesh sieves in the glass flask, add the dichloromethane of 20-50ml (contain the content of the sucrose octaacetate of 16mg / ml n-heptadecanol and 6mg / ml Standard), at room temperature, ultrasonic extraction frequency of 50KHz and ultrasonic power of 350w ultrasonic 10min, after cooling to room temperature, with 5g of anhydrous sodium sulfate filter paper to filter out the smoke.

[0022] b. Concentrating the resulting filtrate to dryness at 10-13kpa. The residue was dilute to 5-10ml with chloroform. Take 1 ml and concentrate to dryness under the protection of inert gas. Add 500ul of 1:1 DMF:BSTFA and react at 60-80°C for 0.5-1.5 hours.

[0023] c. GC-MS analysis is performed on the obtained sample.

Embodiment 2

[0025] a, get two flue-cured tobacco green tobacco leaves, add 2000ml of 1,2-ethylene dichloride in a glass beaker of 5000ml, (containing 16mg / ml n-heptadecanol and 6mg / ml sucrose octaacetate), The tobacco leaves were dipped three times in the beaker for six seconds each time. After dipping, the solution was filtered with filter paper filled with 50 g of anhydrous sodium sulfate.

[0026] b. Concentrating the resulting filtrate to dryness at 10-13kpa. The residue was adjusted to 50ml with dichloromethane. Take 1 ml and concentrate to dryness under the protection of inert gas. Add 500ul of 1:1 DMSO:TMCS and react at 60-80°C for 0.5-1.5 hours.

[0027] c. GC-MS analysis is performed on the obtained sample.

Embodiment 3

[0029] a, get five oriental tobacco green tobacco leaves, add 500ml of chloroform (containing 16mg / ml n-heptadecanol and 6mg / ml sucrose octaacetate) in a 2000ml glass beaker, dip the tobacco leaves in the beaker Dip five times for three seconds each time. After dipping, the solution was filtered with filter paper containing 15 g of anhydrous sodium sulfate.

[0030] b. Concentrating the resulting filtrate to dryness at 10-13kpa. The residue was made up to 10ml with 1,2-dichloroethane. Take 1 ml and concentrate to dryness under the protection of inert gas. Add 500ul of 1:1 DMF:TMCS and react at 60-80°C for 0.5-1.5 hours.

[0031] c. GC-MS analysis is performed on the obtained sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com