Production method of anti-explosion valve sheet, lithium ion battery and anti-explosion cover plate of lithium ion battery

A lithium-ion battery, production method technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problems of affecting sealing, high adhesive curing conditions, low production efficiency, etc., and achieve good air tightness and The effect of explosion-proof, simple and easy production process, good safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

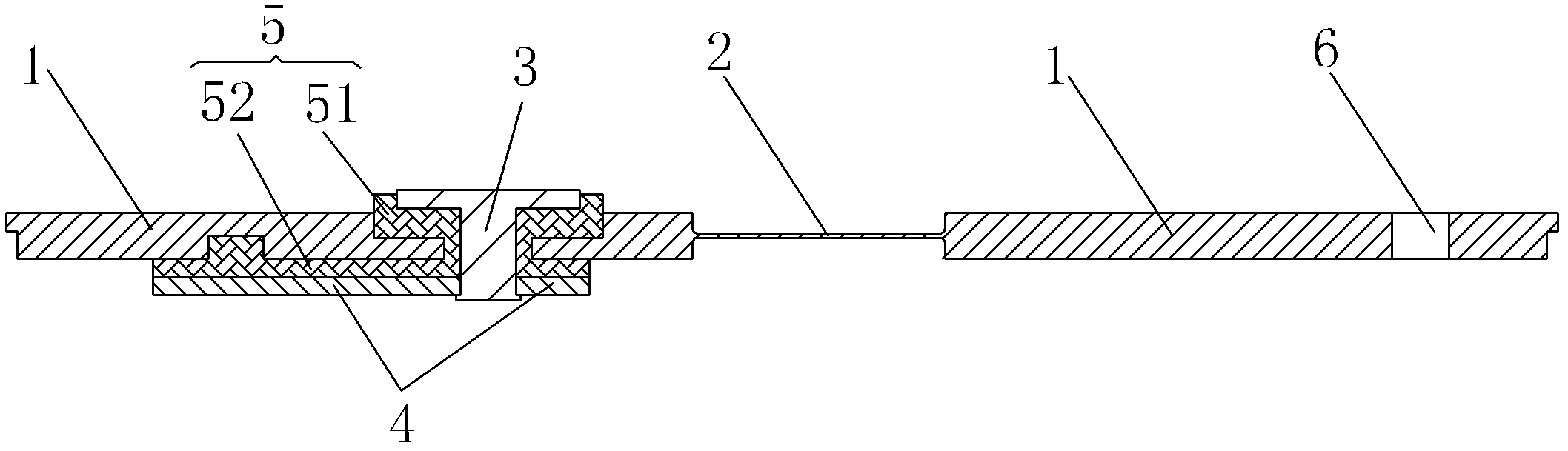

[0011] The production method of the lithium-ion battery explosion-proof valve plate, the lithium-ion battery and its explosion-proof cover plate of the present invention will be described with reference to the accompanying drawings.

[0012] The production method of the lithium-ion battery explosion-proof valve plate of the present invention comprises: performing forging processing on the reserved area on the main cover plate 1 of the explosion-proof cover plate, so that the reserved area forms an airtight film integrally connected with the main cover plate 1 The explosion-proof valve sheet 2 is composed of a film sheet.

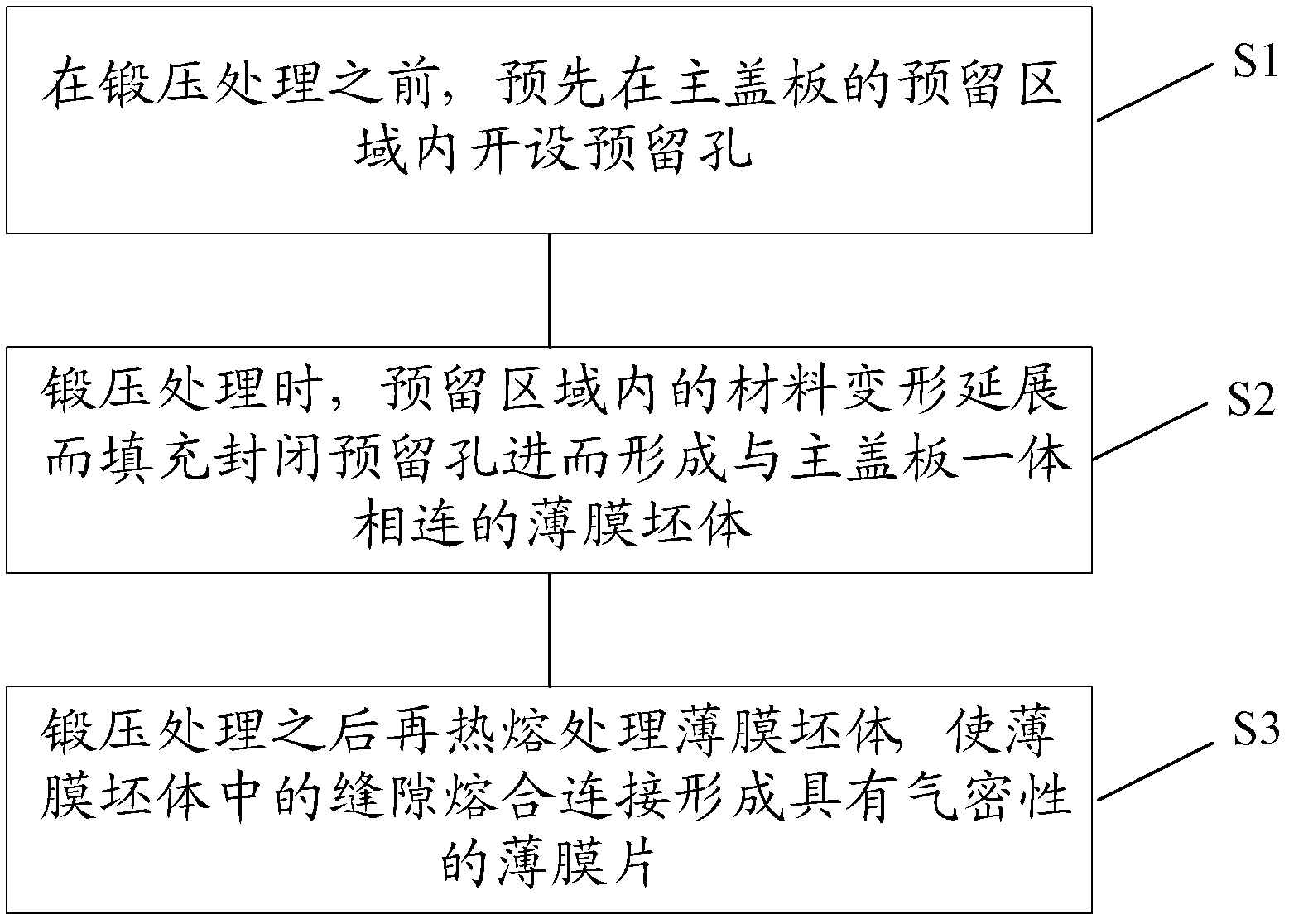

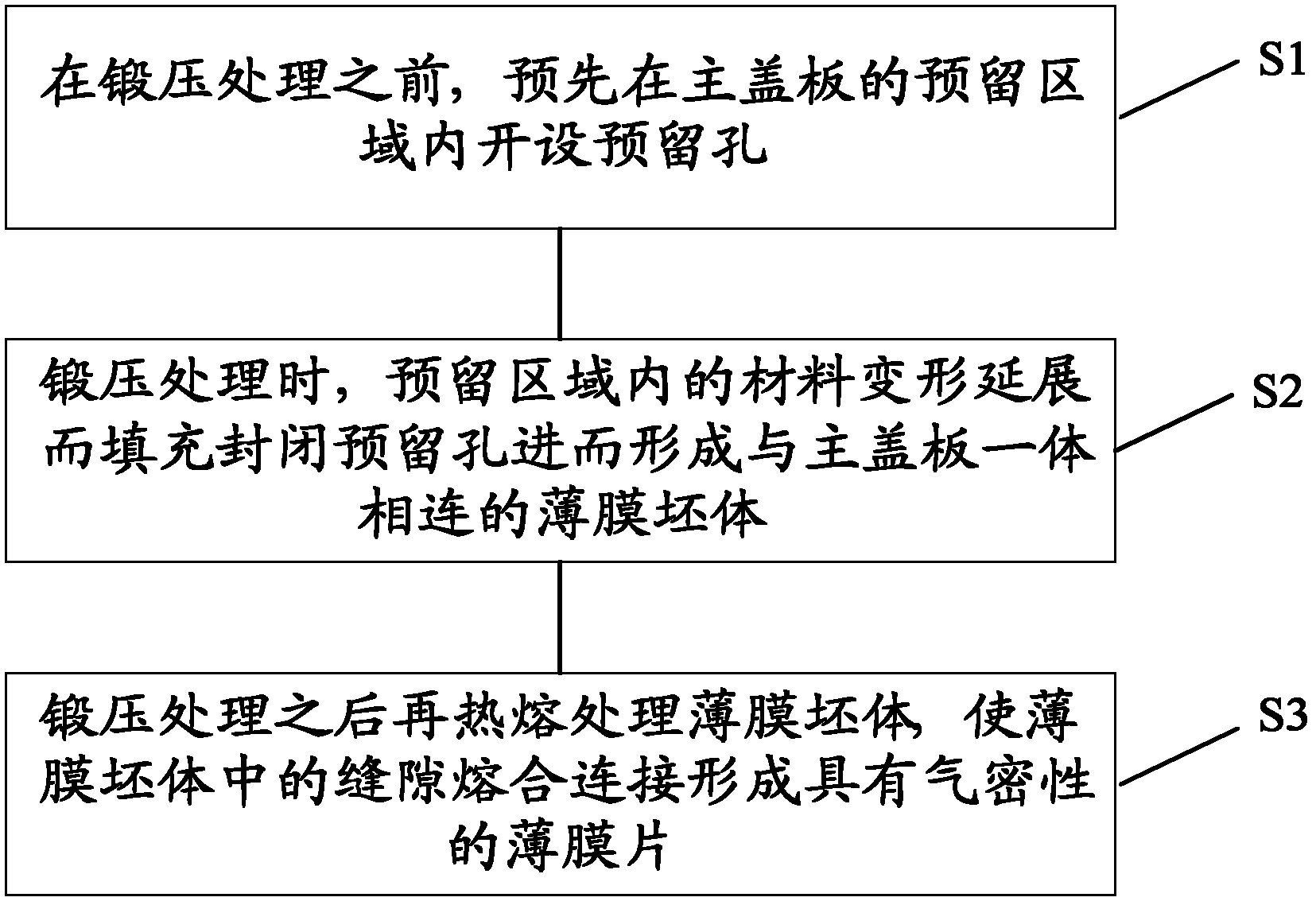

[0013] In specific implementation, such as figure 1 Shown is a flowchart of a method for producing an explosion-proof valve plate in a preferred embodiment of the present invention. This production method comprises the steps:

[0014] S1: before forging the main cover 1 , pre-open a reserved hole in the reserved area of the main cover 1 .

[0015] Speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com