Production process for aqueous environmental-friendly heavy anti-corrosion coating

A production process, heavy-duty anti-corrosion technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of the service life of water-based coatings, unsatisfactory anti-corrosion performance, etc., to achieve good environmental performance and simple production process Ease of use, excellent water and salt water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

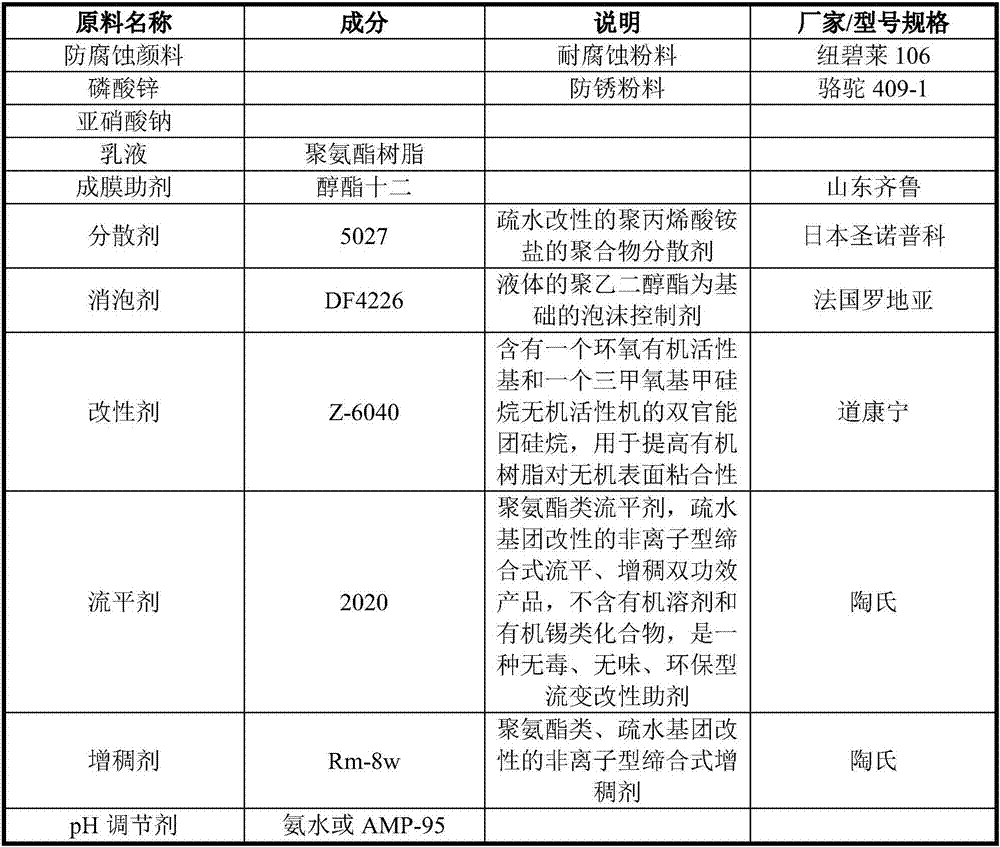

Method used

Image

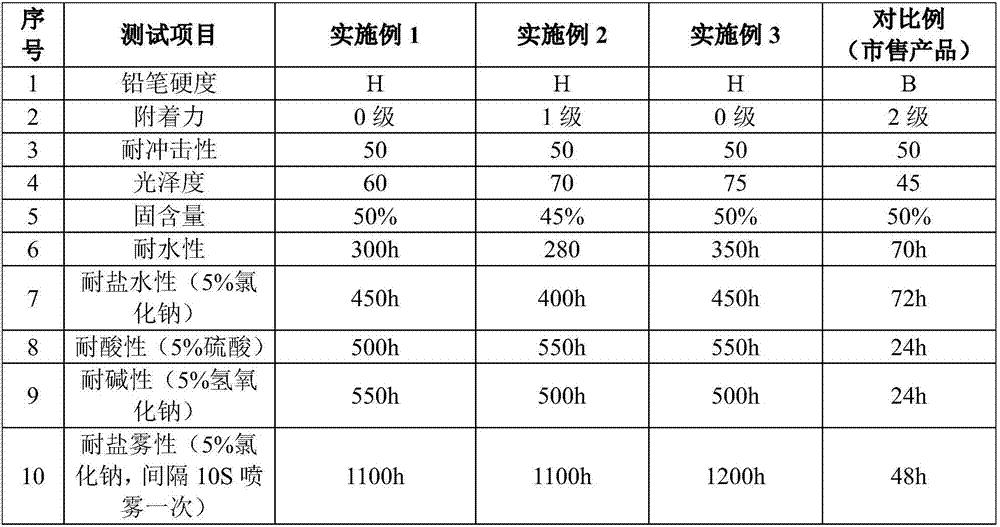

Examples

Embodiment 1~3

[0030] The difference of embodiments 1~3 is that the weight parts of each raw material are different (see Table 2 for details), and the process steps are all the same, specifically comprising the following steps:

[0031] S1. Pour clean water into a 300L dispersing bucket, start the dispersing machine, keep the rotating speed at 600-800rpm, then add dispersant and defoamer to the dispersing bucket, and disperse at a high speed of 600-800rpm for 10min, wherein, the weight part of clean water 200 copies;

[0032] S2. Put anti-corrosion pigments, zinc phosphate and sodium nitrite into the dispersing bucket, disperse at high speed for 20 minutes and stir evenly to obtain a slurry;

[0033] S3, input the slurry obtained in step S2 into a sand mill, and grind until the fineness reaches 20-30 microns;

[0034] S4, pour the emulsion into a dispersing tank of 1200L, start the dispersing machine to disperse, and the rotating speed is 600rpm;

[0035] S5. Input the slurry that has been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com