Debugging-free circular waveguide screw circular polarizer

A circular polarizer and circular waveguide technology, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of difficult to achieve high performance requirements, large debugging workload, difficult processing tolerances, etc. Good processing consistency and the effect of ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

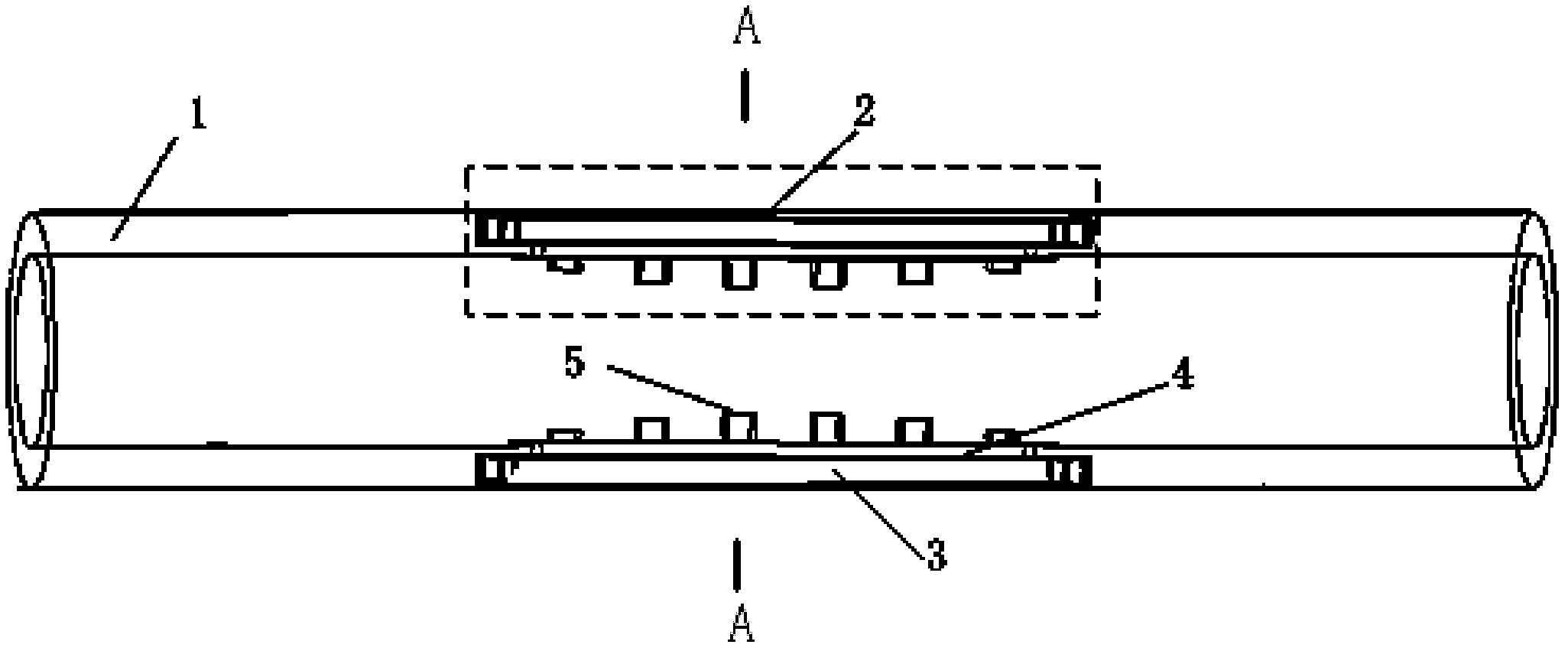

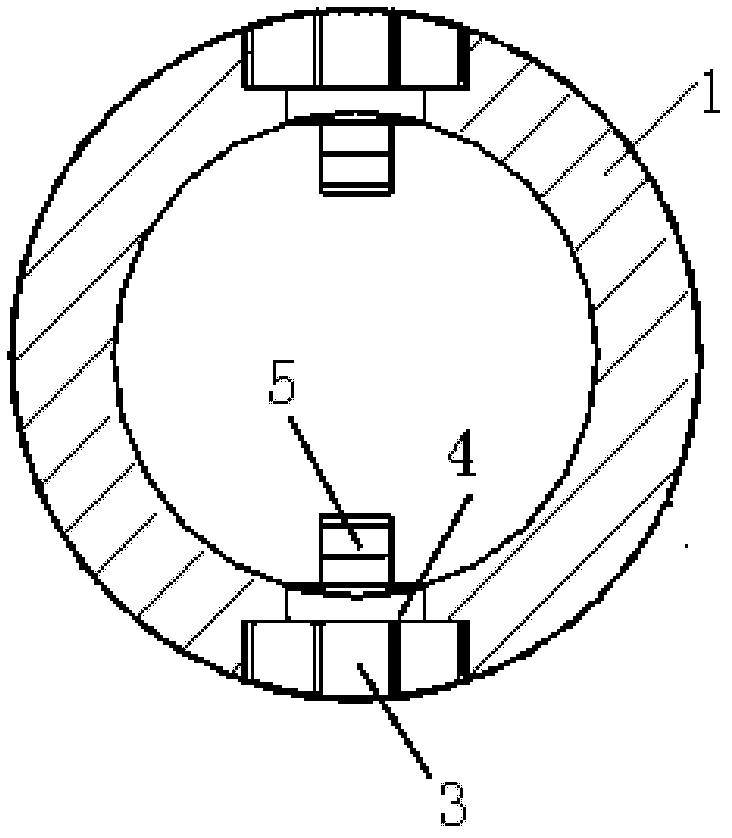

[0014] refer to figure 1 and figure 2 . figure 1 A cylindrical waveguide 1 using metal screws as phase modulating elements is described, and two rows of bidirectionally symmetrical metal integral boss mounting plates 3 on the metal wall of the cylindrical waveguide 1 cavity are placed in the circular waveguide, which constitutes the metal waveguide of the present invention. A best embodiment of screw circular waveguide circular polarizer.

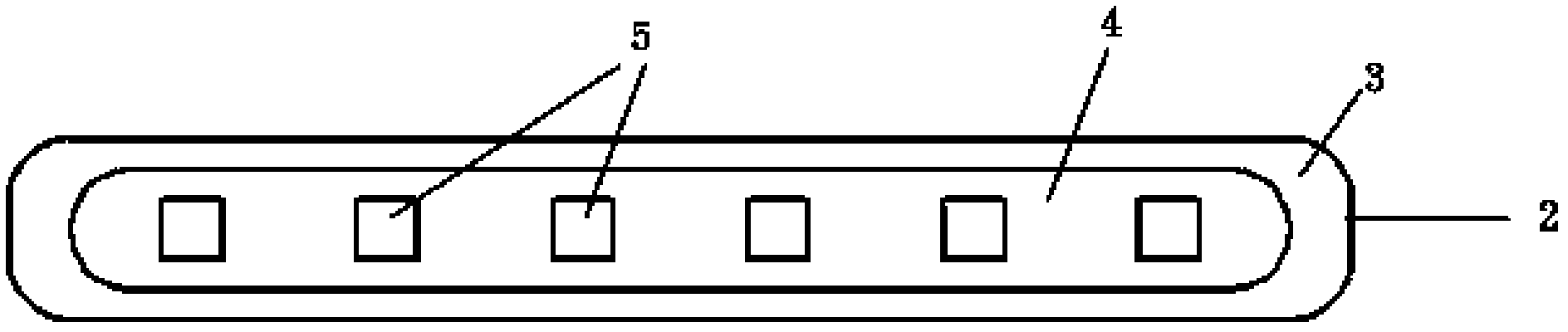

[0015] On the metal wall of the cylindrical waveguide 1, there are grooves symmetrically facing the center line of the cylindrical waveguide 1 in the radial direction, and the grooves are for assembly. image 3 As shown, the metal wall of the cylindrical waveguide (1) is made with a groove symmetrically facing the center line of the cylindrical waveguide (1) in the radial direction, and the groove is an integral component for assembling the metal integral boss mounting plate (3) , longitudinal grooves of complementary structure with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com