Ingot for bearing, and process for producing bearing steel

A bearing steel and manufacturing method technology, applied in the direction of bearings, manufacturing tools, shafts and bearings, etc., can solve the problems of rising manufacturing costs, uneven temperature, large economic burden, etc., and achieve the effect of excellent rolling fatigue resistance characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

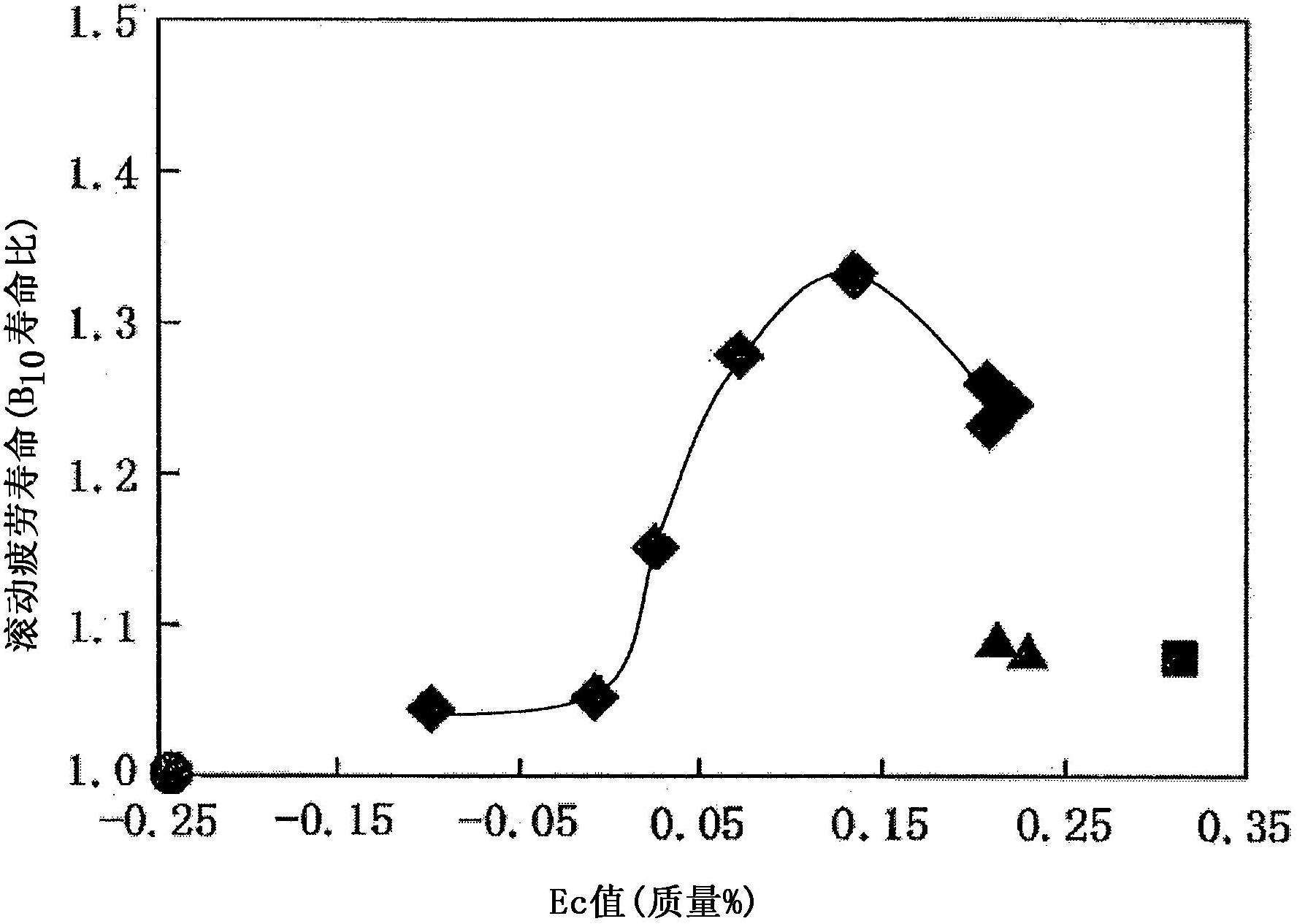

[0123] Steels having the composition shown in Table 3 were melted in a converter refining and degassing process, and then ingots of the dimensions shown in Table 4 were produced by die casting. This ingot was charged into a heating furnace and heated to 1000 to 1350° C., and then forged to the cross-sectional dimensions shown in Table 4. The presence or absence of eutectic carbides and rolling fatigue life characteristics of this forged product were investigated as follows.

[0124] [Presence or absence of eutectic carbide]

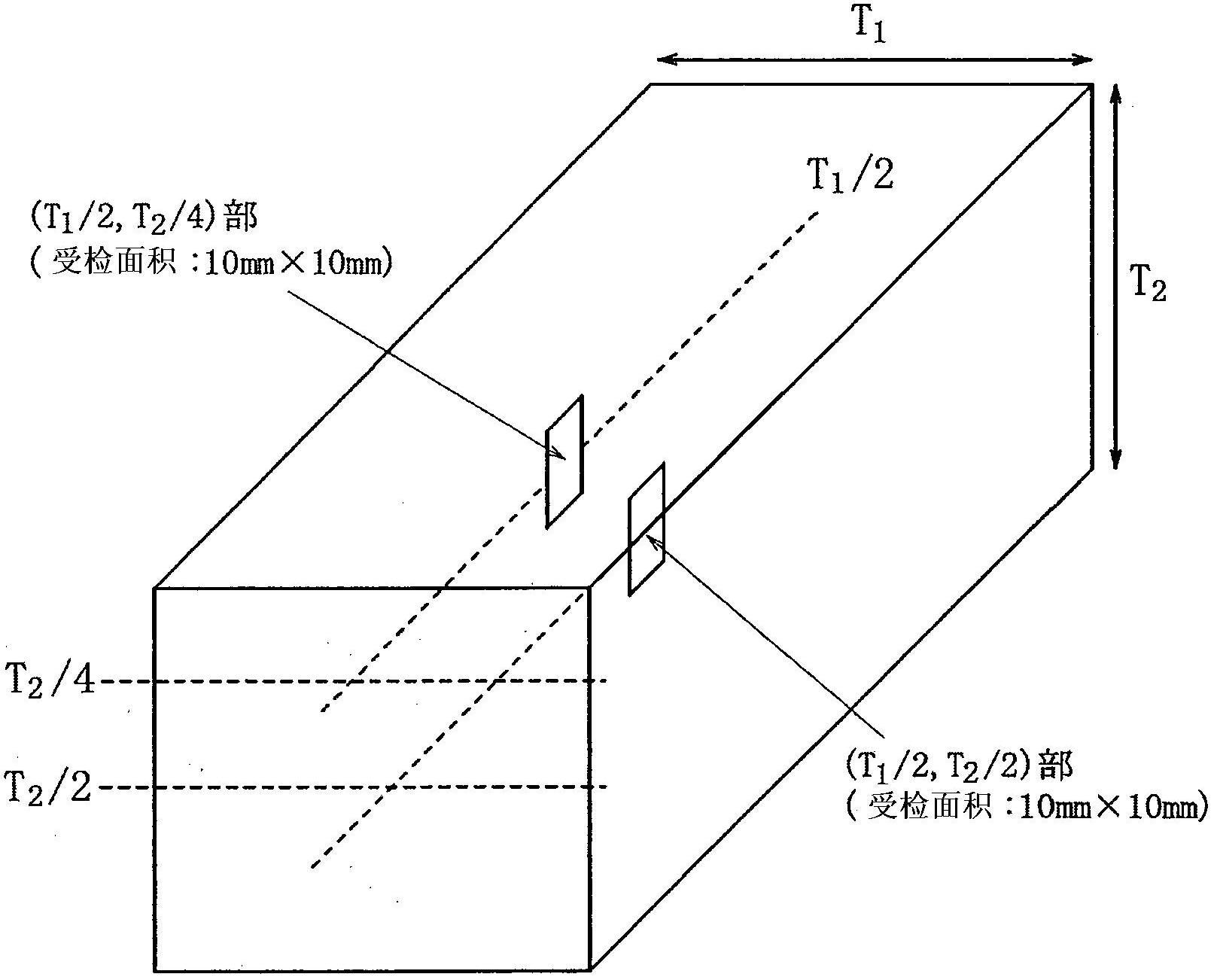

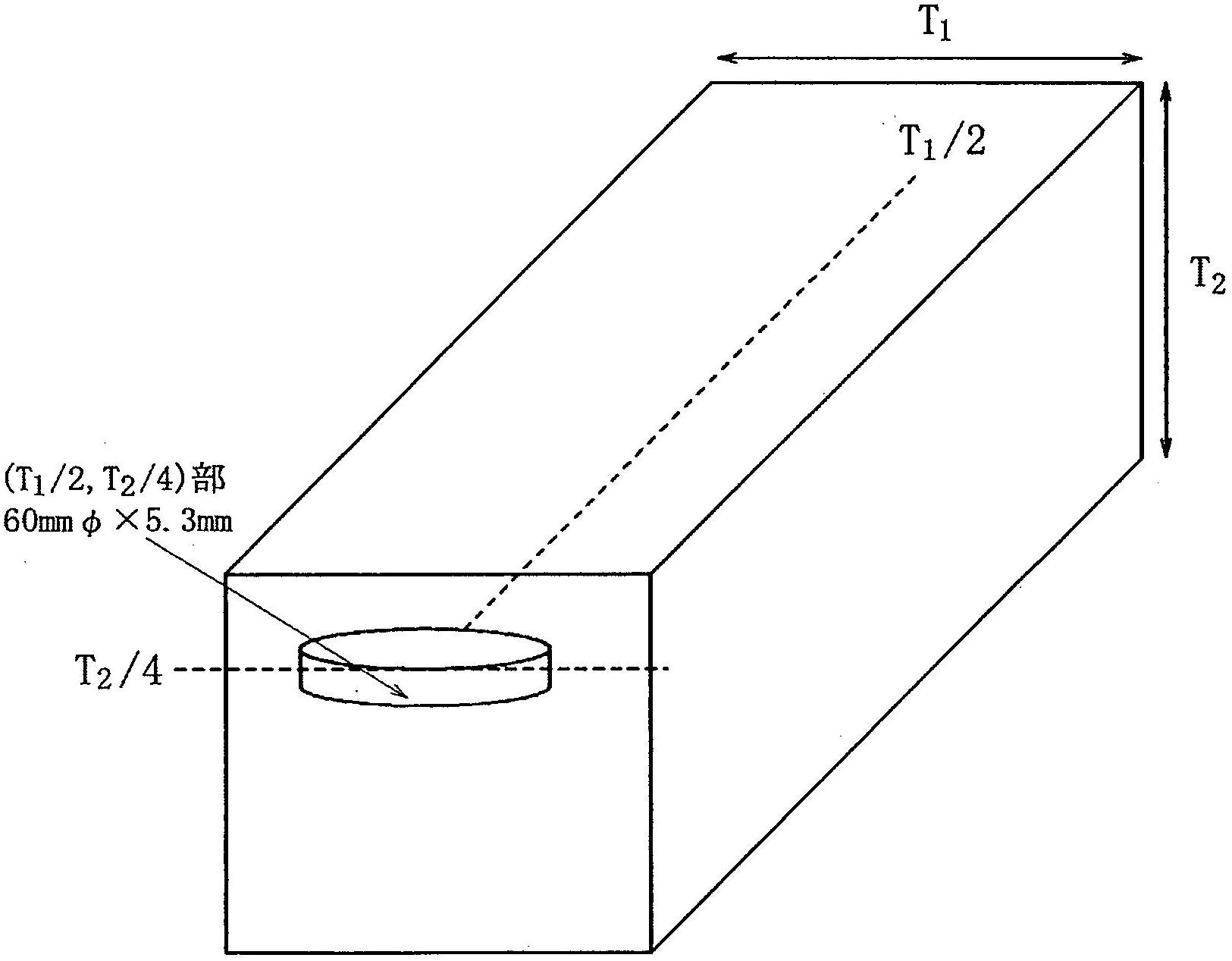

[0125] The presence or absence of eutectic carbides was investigated in the following manner: From (T 1 / 2,T 2 / 2) part (central part) and (T 1 / 2,T 2 / 4) Department (T 1 = T 2 The side length of the square forged steel sheet: figure 2 ) or D / 4 and D / 2 (D is the diameter of the round forged steel sheet: Figure 4 ) so that the cross-section in the direction of extension becomes the observation surface, the sample for microstructure observation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com