Tool path generation method and device

A tool path and target point technology, applied in the field of tool path formation, can solve the problems of inconsistent tool paths and inability to obtain a smooth machined surface, and achieve the effect of smooth machined surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

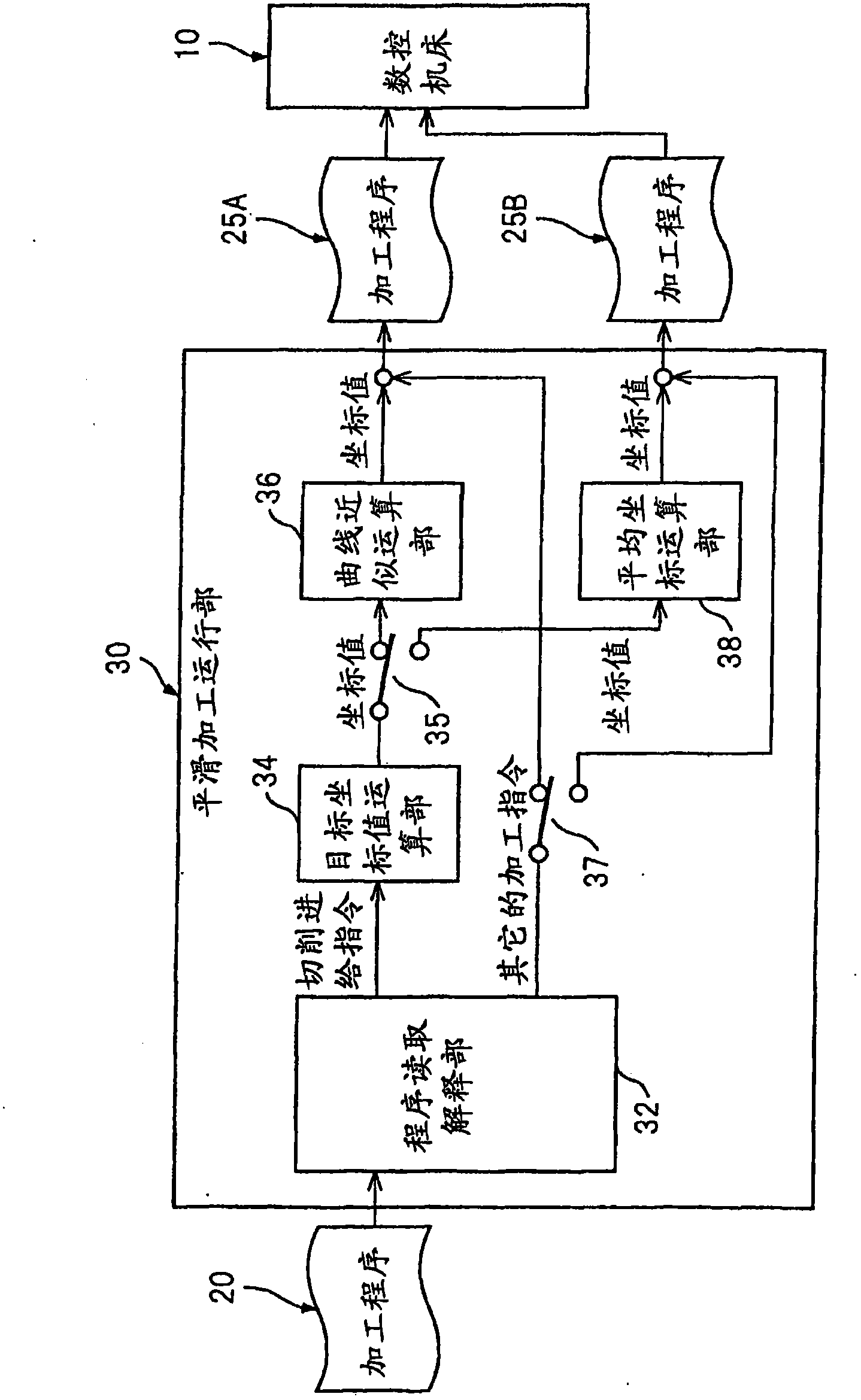

[0023] The tool path forming device of the present invention is not limited to the form of the control device 15 used together with the numerical control machine tool 10 shown in this specification, and may also be used as a CAM device that creates a machining program based on the CAD data of the workpiece, and has a built-in control device. It can be used in the form of a CNC machine tool or a personal computer. The control device 15 can perform smoothing processing after reading the machining program created by the CAM device to form a tool path, and rewrite the machining program 20 based on the formed tool path. The rewritten machining programs 25A, 25B are stored in a memory in the device, and can be read out to be used by other machine tools, or to partially edit the contents of the machining programs. In addition, the apparatus may be configured so as not to have the function of rewriting the machining program or the function of storing the machining program. The contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com