Self-cleaning type air filtering material and preparation method thereof

An air filter material, self-cleaning technology, applied in the field of filtration, can solve problems such as easy peeling or damage, weak electrospinning layer strength, delamination, peeling, etc., to achieve good processing and use performance, wide performance control range, Restoring the effect of filter performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

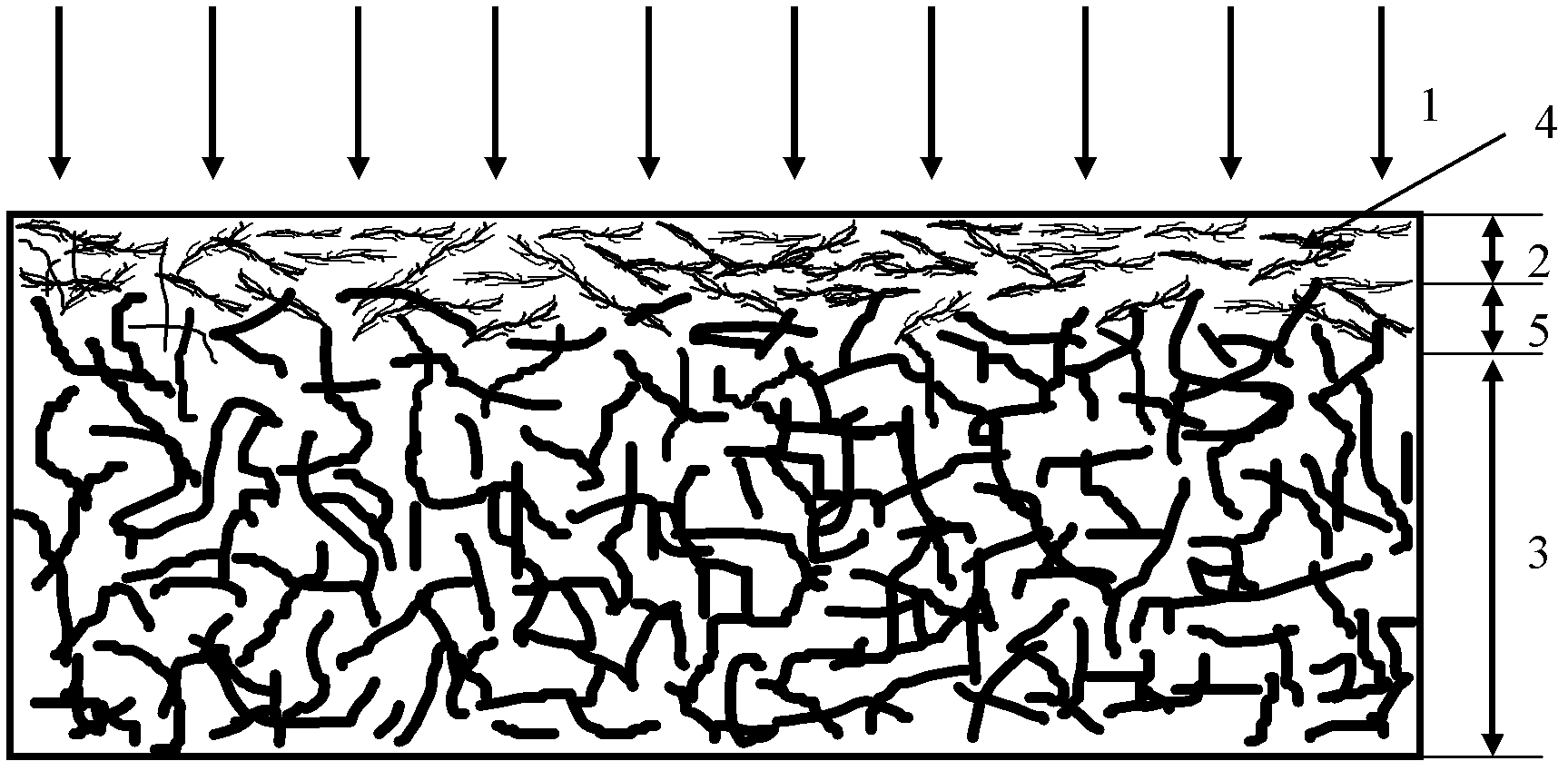

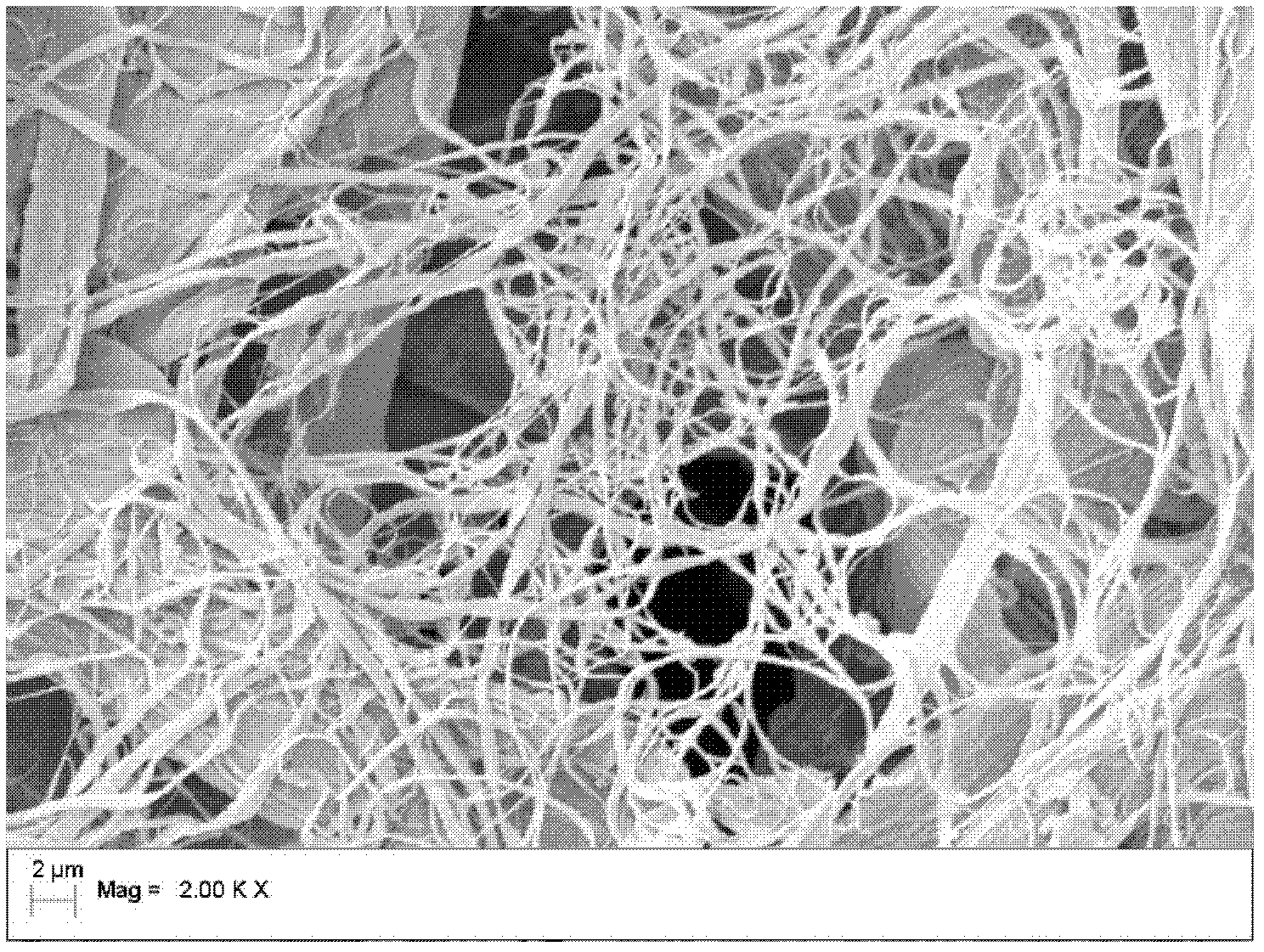

[0031] Example 1 Self-cleaning air filter material provided by the invention

[0032] This embodiment provides a preparation method of a self-cleaning air filter material.

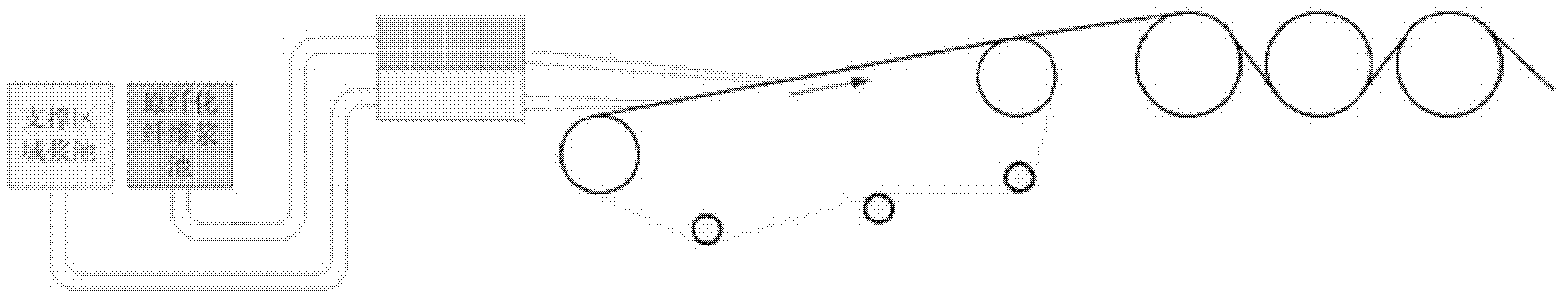

[0033] The preparation process of self-cleaning air filter material can be found in image 3 , the specific details are as follows:

[0034] 1) Mix the fibrillated tencel fiber slurry and the fibrillated aramid fiber slurry used to form the submicron fiber layer in the stock tank at a weight ratio of 1:9 to obtain a submicron fiber layer with a certain concentration fiber suspension;

[0035] 2) Mixing the wood fiber slurry and the polyester fiber slurry used to form the support area in another slurry tank at a weight ratio of 6:4 to obtain a fiber suspension of a certain concentration in the support area;

[0036] 3) The submicron fiber layer fiber suspension and the support region fiber suspension are respectively sent to the forming wire through the double-layer headbox, and the support region fibe...

Embodiment 2

[0050] Example 2 Research on the self-cleaning air filter material provided by the invention

[0051] With reference to the preparation method provided in Example 1, the quantification of the submicron fiber layer of the self-cleaning air filter material was studied, wherein the supporting regions all used 60% wood fibers and 40% polyester fibers with a diameter of 9 μm, and the quantification was 90g / m 2 . The results are shown in Table 1.

[0052] Table 1

[0053]

[0054] It can be seen from Table 1 that although the filtration efficiency increases with the increase of the submicron fiber layer weight, the increase speed of the filtration efficiency is significantly lower than the increase speed of the filtration resistance. Excessive resistance is very detrimental to the filtration process. Therefore described submicron fiber layer quantification should not exceed 10g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com