Polyethylene compound used for long-service-life electrolysis cathode plate sealing strip and preparation method thereof

A technology for electrolytic cathode plates and sealing strips, which is applied in the field of metal wet electrolysis, can solve the problems of short life and low toughness of edge strips, and achieve the effects of improving life, increasing adhesion, and reducing catalytic degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

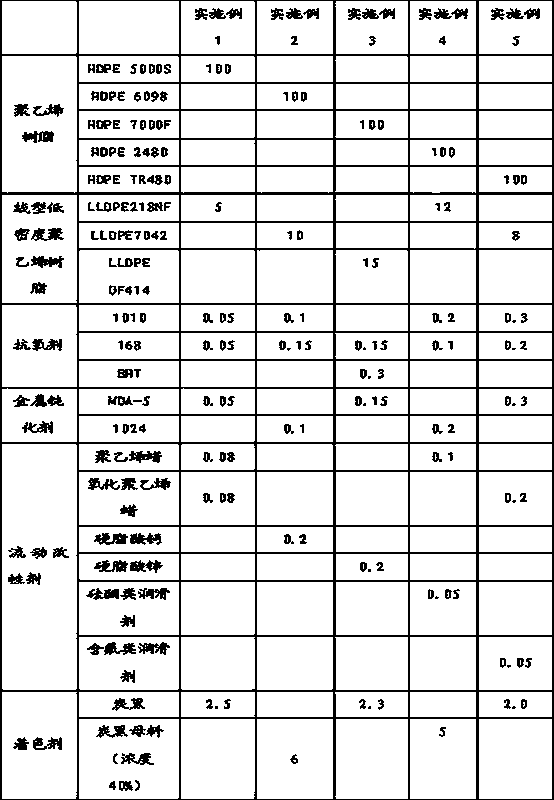

[0021] The present invention proposes long-life electrolytic cathode plate sealing strip polyethylene compounding material and its preparation method. The materials it adopts include: polyethylene resin, linear low-density polyethylene resin, antioxidant, metal passivator, flow modifier , Appropriate amount of coloring agent.

[0022] The polyethylene resin is copolymerized high-molecular-weight medium-density or high-density polyethylene, and the requirements for various performance indicators are: the comonomer is α-olefin, and its density is ≥ 0.940g / cm 3 , Melt flow rate ≤ 1.0g / 10min.

[0023] The linear low density polyethylene resin is a copolymer, the comonomer is α-olefin, and its density is ≤0.926g / cm 3 , Melt flow rate ≤ 2.0g / 10min. The purpose of adding linear low density polyethylene resin is to further improve the toughness of the composition.

[0024] The antioxidant is a hindered phenolic substance, and its function is to capture the free radicals formed by h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com