Friction machine for fabrication of liquid crystal cell, liquid crystal cell and its fabrication method, and liquid crystal display device

A processing method and rubbing machine technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as hair cutting and warping of the orientation layer on the substrate, so as to avoid uneven friction force, impurity pollution, and edge-free warping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment describes a rubbing machine for orientation processing of liquid crystal cells, comprising a rubbing roller and a rubbing cloth driven by the rubbing roller, and the rubbing machine is provided with at least three rubbing rollers arranged from front to back, Wherein the bottom of the first friction roller is higher than the bottom of the second friction roller, the friction cloth between the bottom of the first friction roller and the bottom of the second friction roller and the surface to be rubbed form an acute angle of introduction inclination , the second friction roller is set at the same height as the bottom of other friction rollers.

Embodiment 2

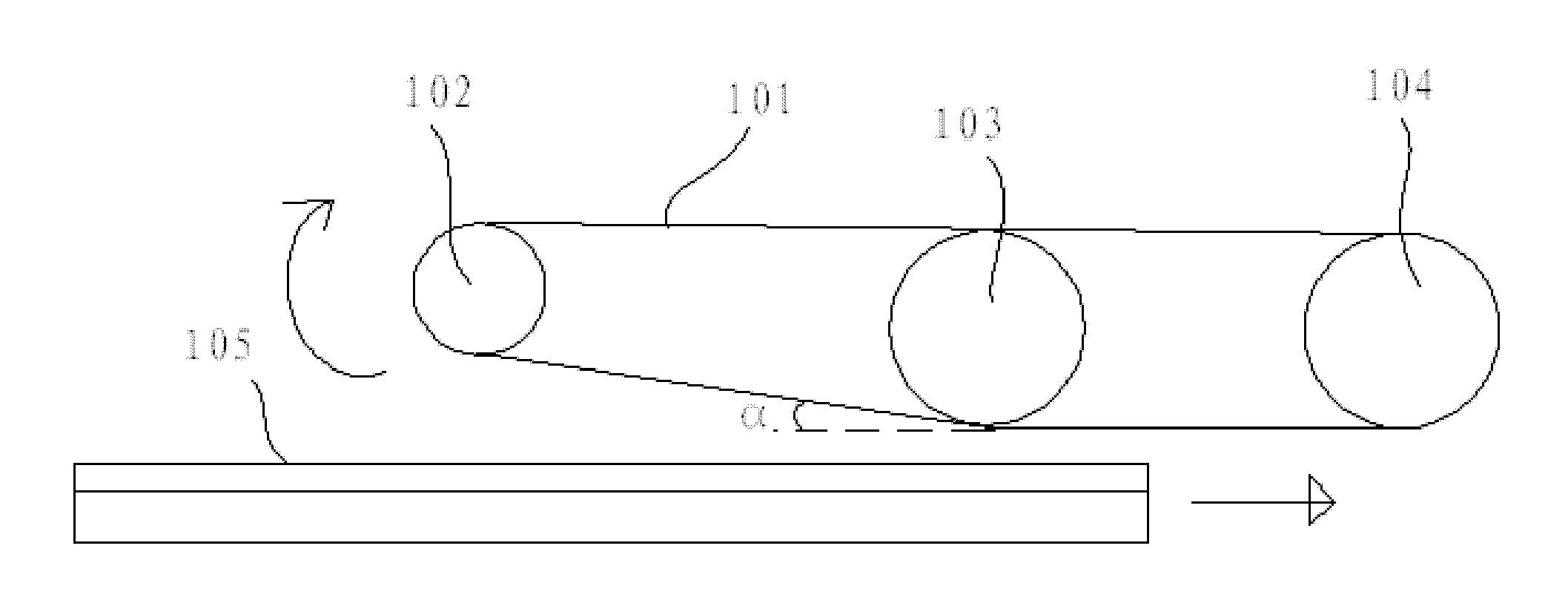

[0038] Such as figure 1 As shown, this embodiment describes a kind of rubbing machine for liquid crystal cell orientation processing, including from front to back ( figure 1 The first friction roller 102, the second friction roller 103, the third friction roller 104 and the friction cloth 101 moving under the drive of the three friction rollers are arranged in sequence from left to right in the center, wherein the bottom of the first friction roller 102 Higher than the bottom of the second friction roller 103, between the friction cloth 101 between the bottom of the first friction roller 102 and the bottom of the second friction roller 103 and the surface to be rubbed 105 forms an acute angle of introduction inclination α, the first The bottoms of the two friction rollers 103 and the third friction roller 104 are arranged at the same height.

[0039] Preferably, in this embodiment, the introduction inclination angle α is 8-15 degrees.

[0040] Depend on figure 1 It can be s...

Embodiment 3

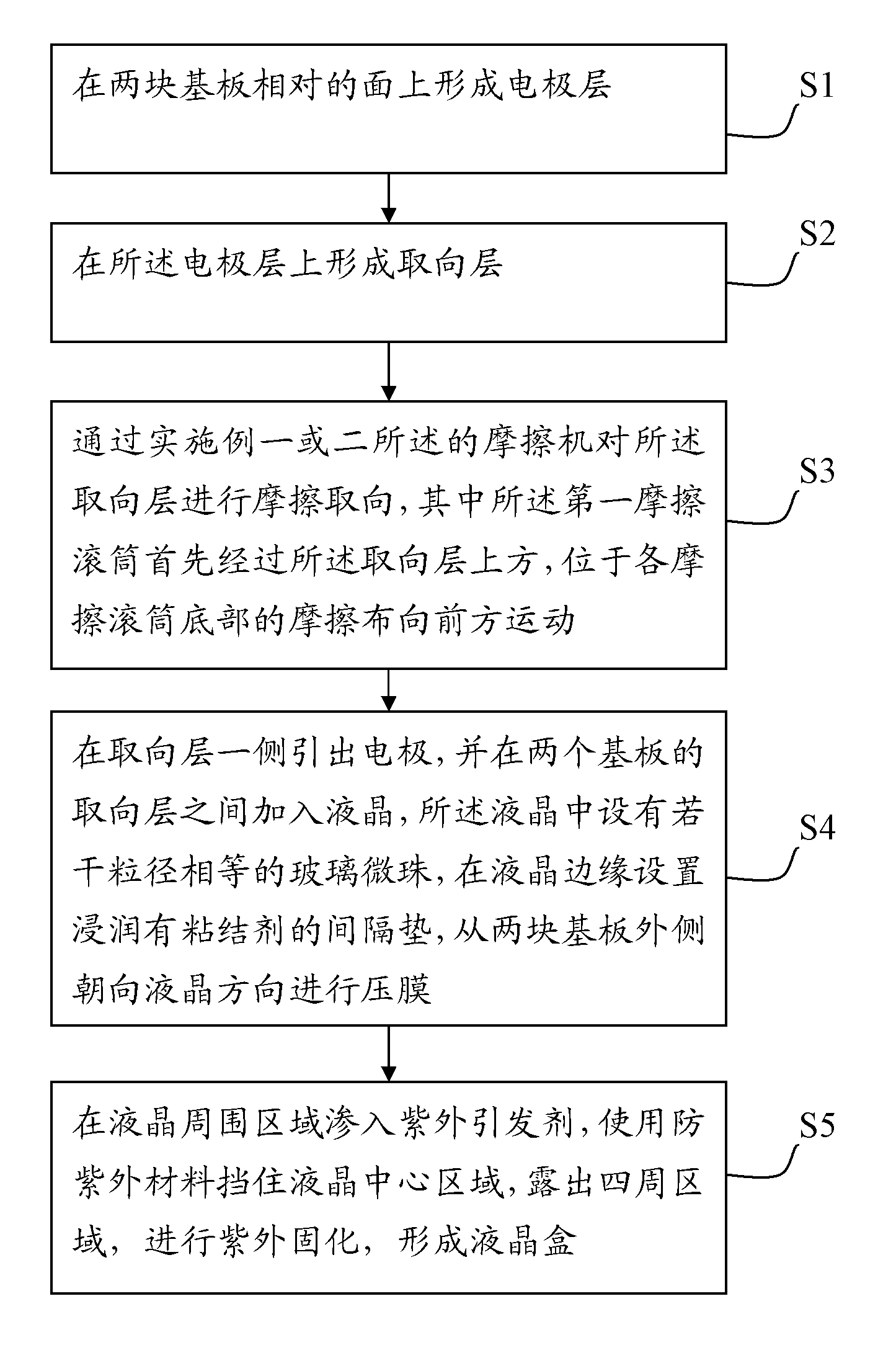

[0043] Such as figure 2 As shown, this embodiment describes a liquid crystal cell processing method, comprising the following steps:

[0044] S1: forming electrode layers on the opposite surfaces of the two substrates;

[0045] S2: forming an alignment layer on the electrode layer;

[0046] S3: Rubbing and aligning the orientation layer by the rubbing machine described in Embodiment 1 or Embodiment 2, such as figure 1 As shown, wherein the first friction roller first passes above the orientation layer, and the friction cloth at the bottom of each friction roller moves forward;

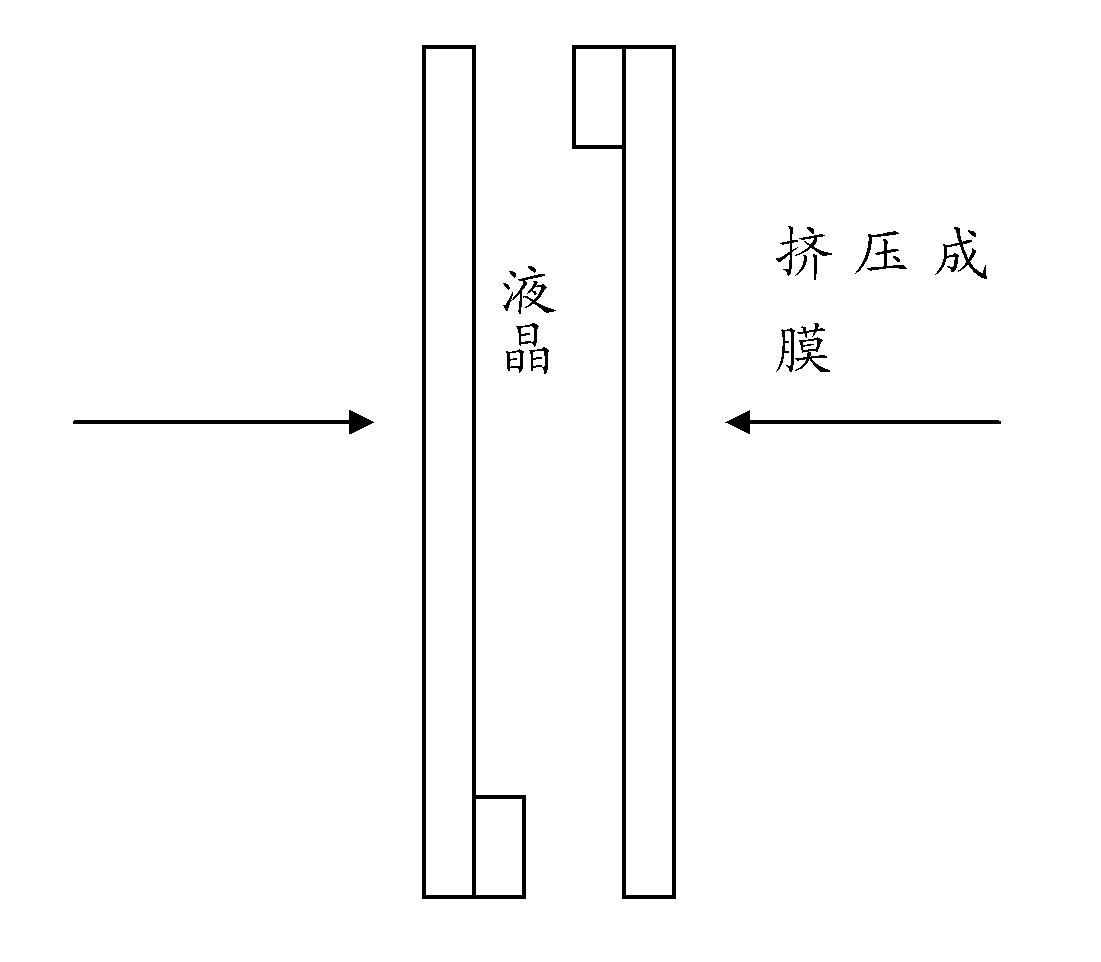

[0047] S4: Draw out the electrodes on one side of the alignment layer, and add liquid crystal between the alignment layers of the two substrates. The liquid crystal is provided with a number of glass beads with the same particle size, and a spacer soaked with adhesive is placed on the edge of the liquid crystal. , lamination is carried out from the outside of the two substrates toward the direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com