Scanning electron microscope (SEM) sample fixture used in on line SEM observing and SEM sample observing method

A sample observation and sample technology, applied in the direction of material analysis, discharge tube, electrical components, etc. by measuring secondary emissions, can solve the problems that online SEM cannot conduct SEM sample/section observation, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

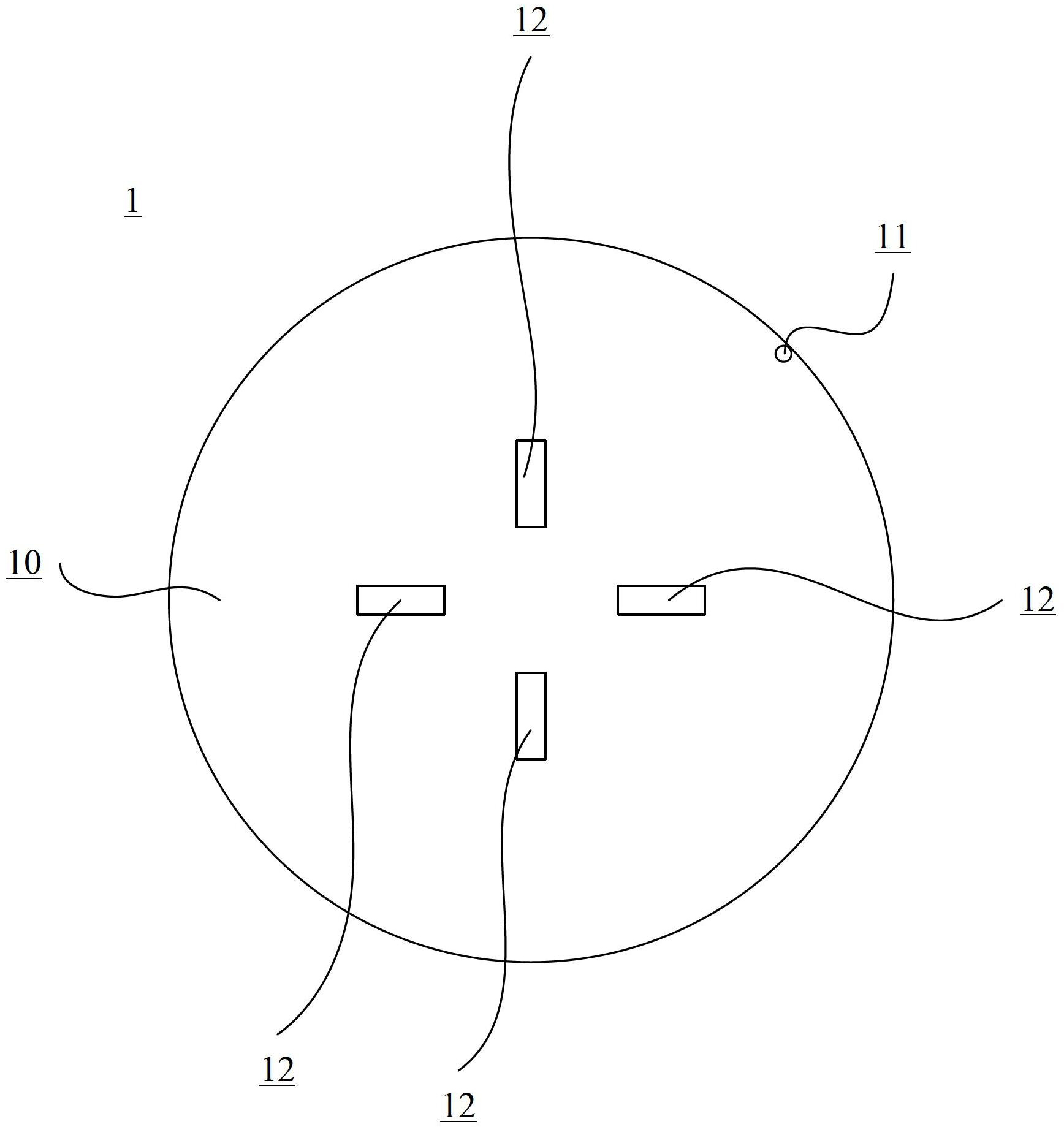

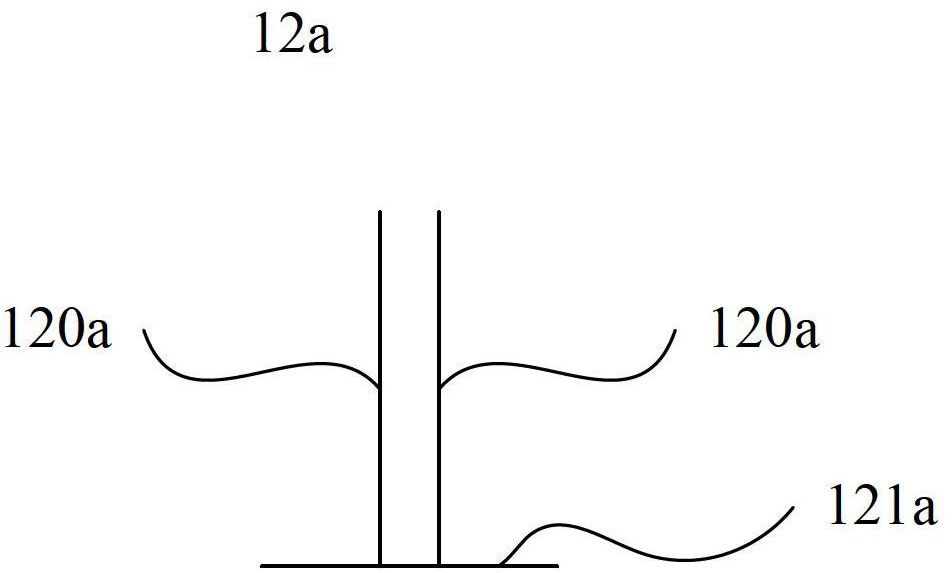

[0048] Please refer to Figure 1a~1b ,in, Figure 1a It is a schematic top view of the SEM sample fixture for online SEM observation according to Embodiment 1 of the present invention; Figure 1bIt is a schematic side view of the SEM sample fixture used for online SEM observation in Example 1 of the present invention.

[0049] like Figure 1a As shown, the SEM sample holder 1 includes:

[0050] A disc-shaped metal support 10, the disc-shaped metal support 10 is provided with a Notch notch 11;

[0051] The disc-shaped metal bracket 10 has one or more grooves 12 .

[0052] Specifically, the disc-shaped metal stent 10 has a diameter of 150 mm to 300 mm and a thickness of 0.4 mm to 6 mm. Usually, the shape of the disc-shaped metal support 10 is equivalent to the size of the wafer on the production line, that is, for example, the wafer on the production line is a 6-inch wafer, then the shape and size of the disc-shaped metal support 10 It is basically the shape and size of a 6-...

Embodiment 2

[0061] Please refer to Figure 3a~3b ,in, Figure 3a It is a schematic bottom view of the SEM sample fixture for online SEM observation according to the second embodiment of the present invention; Figure 3b It is a schematic side view of the SEM sample fixture used for online SEM observation according to the second embodiment of the present invention.

[0062] like Figure 3a As shown, the SEM sample holder 3 includes:

[0063] A disc-shaped metal support 30, the disc-shaped metal support 30 is provided with a Notch notch 31;

[0064] The disc-shaped metal bracket 30 has one or more grooves 32;

[0065] The disc-shaped metal bracket 30 has a thickened area 33 , and each groove 32 is partially located on the thickened area 33 .

[0066] The difference between this embodiment and the first embodiment is that a thickened area 33 is provided on the disc-shaped metal bracket 30 , and at the same time, each groove 32 is partially located on the thickened area 33 . For the vac...

Embodiment 3

[0069] Please refer to Figure 4a~4b ,in, Figure 4a It is a schematic bottom view of the SEM sample fixture for online SEM observation according to Embodiment 3 of the present invention; Figure 4b It is a schematic side view of the SEM sample fixture used for online SEM observation according to Example 3 of the present invention.

[0070] like Figure 4a As shown, the SEM sample holder 4 includes:

[0071] A disc-shaped metal support 40, the disc-shaped metal support 40 is provided with a Notch notch 41;

[0072] The disc-shaped metal bracket 40 has one or more grooves 42;

[0073] The disc-shaped metal bracket 40 has a thickened area 43 , and each groove 42 is partially located on the thickened area 43 . For the vacuum observation chamber of the SEM equipment, the chuck carrying the silicon chip is generally circular, and the thickened region 43 is positioned at the back side of the disc-shaped metal support 40, and the disc-shaped metal support 40 is placed When on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com