A kind of modified graphene composite slurry with high dispersion stability and preparation method thereof

A graphene composite and graphene technology, applied in the graphene field, can solve the problems of poor graphene dispersion, limit graphene's high electrical conductivity, high thermal conductivity, etc., achieve simple additives, prolong stable storage time, preparation steps and conditions simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

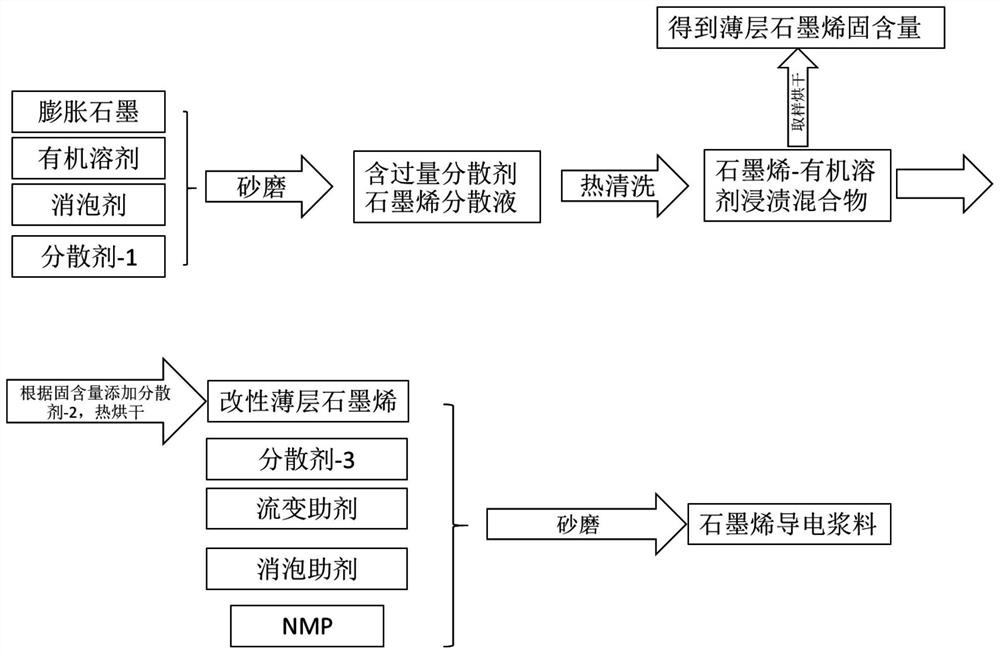

[0079] The present invention also provides a method for preparing the modified graphene composite slurry as described in any one of the above-mentioned technical solutions, comprising the following steps:

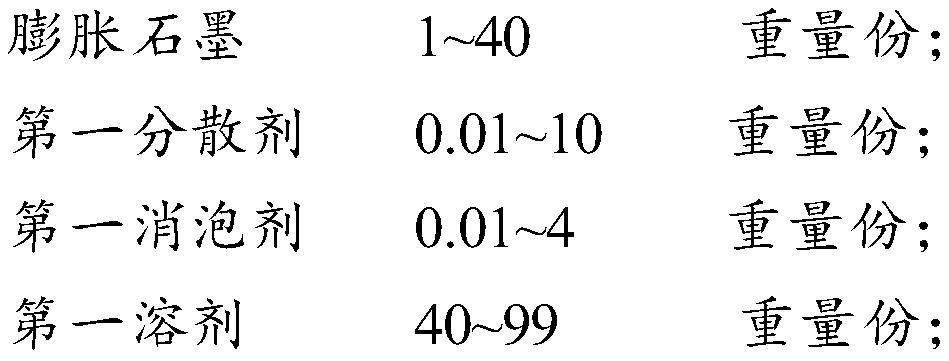

[0080] 1) After grinding and mixing the expanded graphite, the first dispersant, the first defoamer and the first solvent, a mixed solution is obtained;

[0081] 2) After the mixed solution obtained in the above steps is hot-filtered and cleaned using the second solvent, a modified graphene solution is obtained;

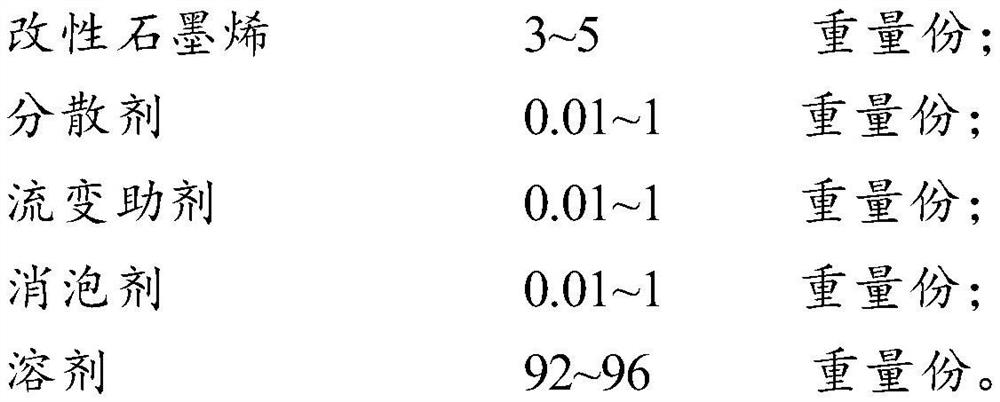

[0082] 3) After grinding and mixing the modified graphene, dispersant, rheological additive, defoamer and solvent again, the modified graphene composite slurry is obtained.

[0083] In the present invention, the selection and composition of raw materials in the preparation method of the modified graphene composite slurry, and the corresponding optimization principles, the selection and composition of the corresponding raw materials in the aforementioned modified g...

Embodiment 1

[0119] 1. Using expanded graphite produced by Shandong Oupo New Material Co., Ltd. as raw material, add a certain amount of dimethylformamide, polyvinylpyrrolidone, and polydimethylsiloxane. Wherein each component ratio is as follows:

[0120] Expanded graphite ---- 25 parts

[0121] Dispersant -----10 parts

[0122] Defoamer - 1 part

[0123] Solvent - 64 parts

[0124] 2. Grind the mixture in step 1 in a high-energy sand mill with a rotating speed of 2500r / min, a grinding time of 240min, a zirconium bead filling rate of 70%, and a zirconium bead size of 0.8mm.

[0125] 3. The mixed solution in step 2 is cleaned by hot filtration, and the solvent is tetrahydrofuran, which is a volatile solvent, and the solid content is tested by sampling.

[0126] 4. Add a certain amount of dispersant according to the solid content, dispersant: thin-layer graphene=0.4:4, and heat-dry to obtain a dispersant-modified thin-layer graphene mixture.

[0127] 5. Mix the modified thin-layer grap...

Embodiment 2

[0135] 1. Using expanded graphite as raw material, add a certain amount of methanol and water mixture, polyvinylpyrrolidone, and polydimethylsiloxane. Wherein each component ratio is as follows:

[0136] Expanded graphite ---- 30 parts

[0137] Dispersant ----- 8 parts

[0138] Defoamer ---- 2 parts

[0139] Methanol----30 parts

[0140] Water------30 parts

[0141] 2. Grind the mixture in step 1 in a high-energy sand mill with a rotating speed of 3000r / min, a grinding time of 300min, a zirconium bead filling rate of 60%, and a zirconium bead size of 0.2mm.

[0142] 3. The mixed solution in step 2 is cleaned by hot filtration, and the solvent is tetrahydrofuran, which is a volatile solvent, and the solid content is tested by sampling.

[0143] 4. Add a certain amount of dispersant according to the solid content, dispersant: thin-layer graphene=0.2:4, and heat-dry to obtain a dispersant-modified thin-layer graphene mixture.

[0144] 5. Mix the modified thin-layer graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com