A kind of ruthenium oxide-copper sulfide composite material, application and a kind of electrode sheet for supercapacitor

A technology of supercapacitors and composite materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of limited application and high price of ruthenium oxide, and can overcome the high cost, improve the specific capacitance, and increase the contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

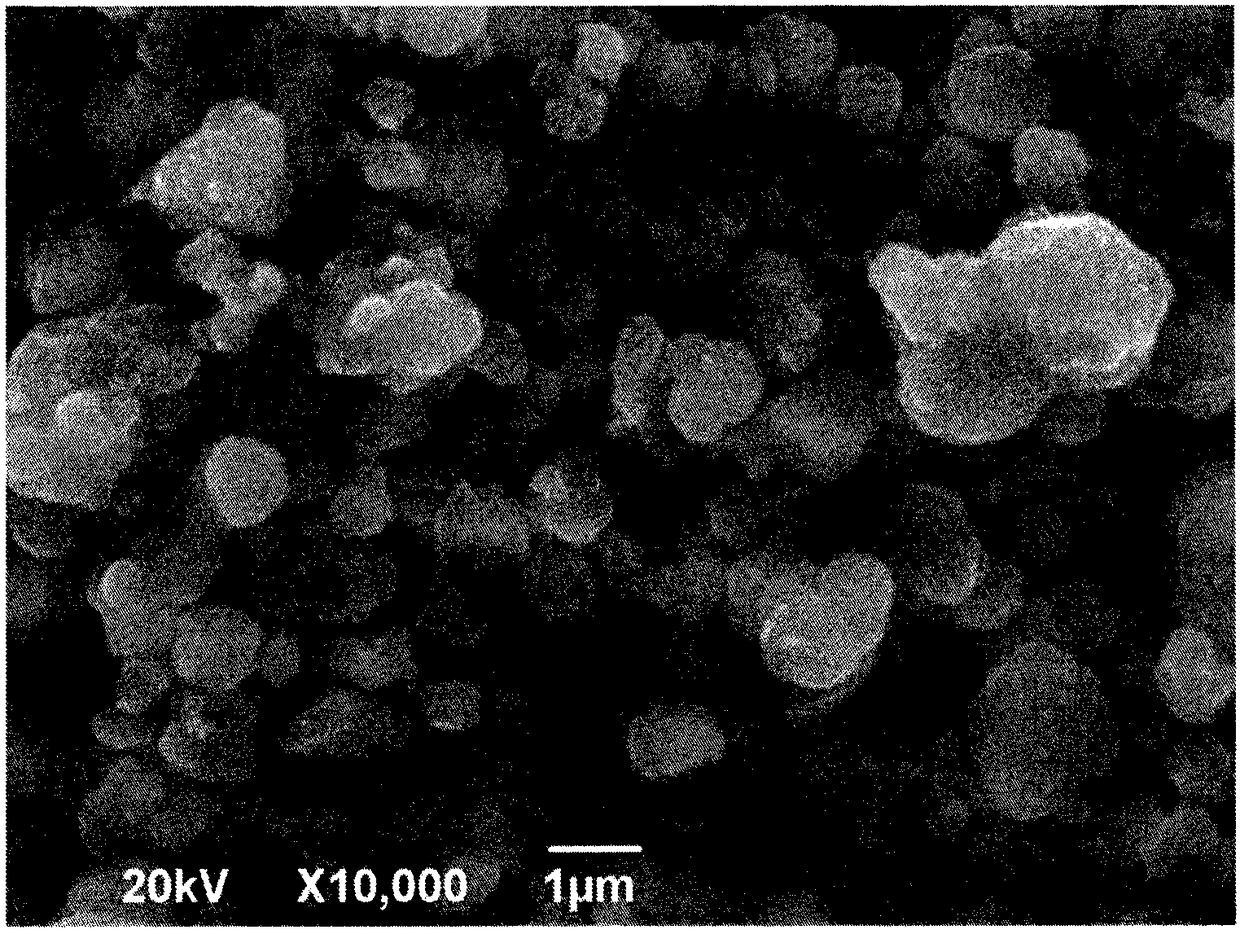

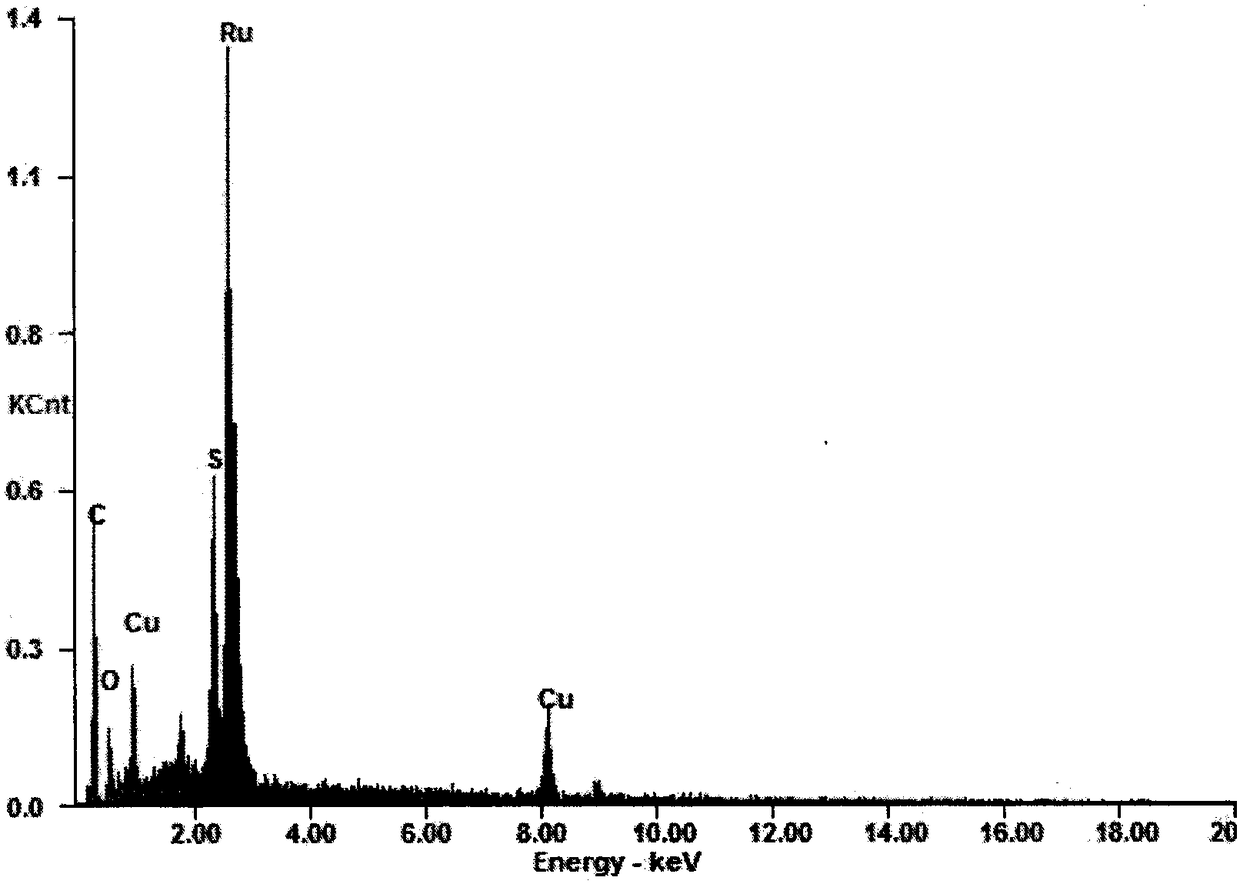

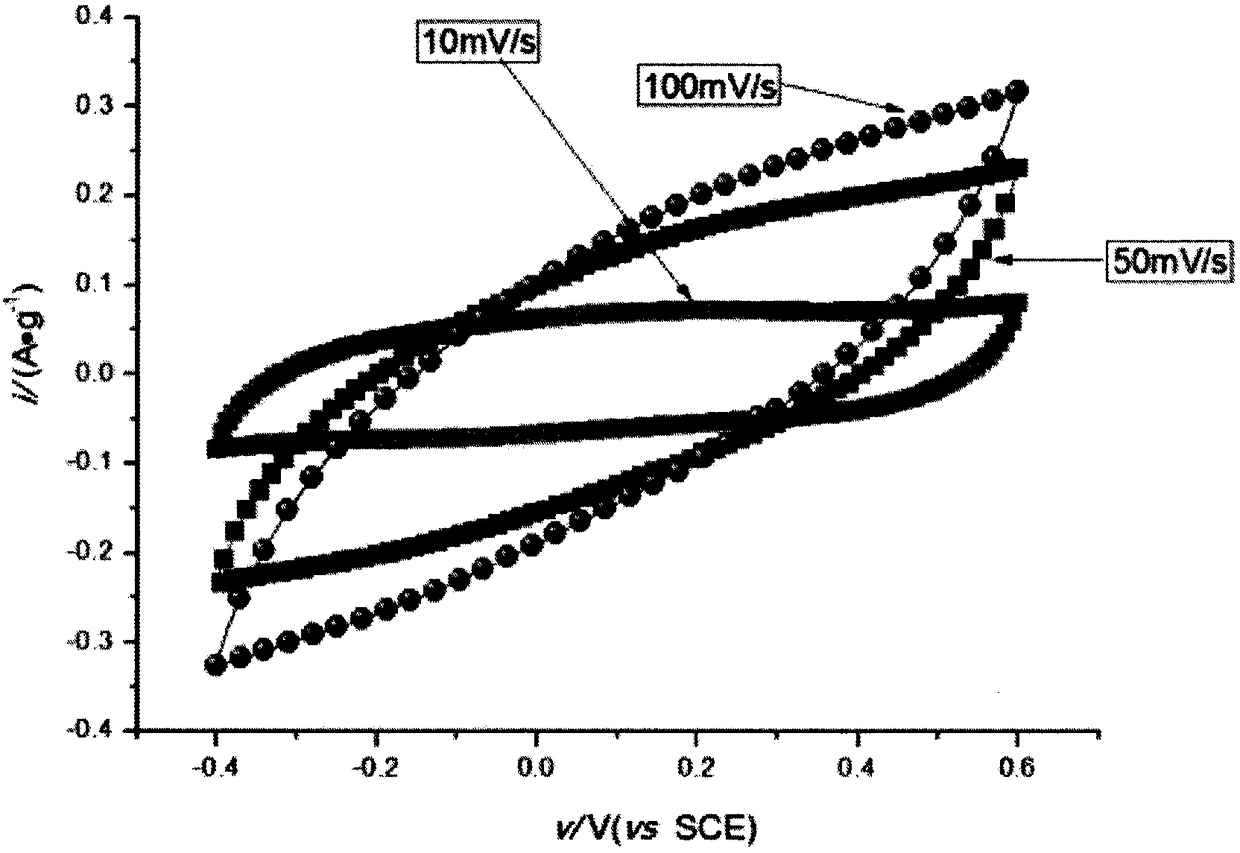

[0040] A ruthenium oxide-copper sulfide composite material, comprising 64% by weight of ruthenium oxide hydrate, 16% by weight of copper sulfide, 10% by weight of a conductive agent, and 10% by weight of 10% binder composition.

[0041] Its preparation method comprises the following steps

[0042] (1) Preparation of copper sulfide nanomaterials;

[0043] Ultrasonically dissolve copper chloride hydrate in ethylene glycol, then add thiourea to the above reaction system, and stir for 0.5h to 1h;

[0044] After the above stirring, after hydrothermal reaction at 150°C-200°C for 8h-12h, suction filtration, water washing, alcohol washing, and drying at 150°C-200°C for 24h, the copper sulfide nanomaterial is obtained;

[0045] (2) preparation of ruthenium trichloride solution;

[0046] Dissolving hydrated ruthenium trichloride in 40ml to 60ml of water to obtain a 10mg / ml to 20mg / ml ruthenium trichloride solution;

[0047] (3) Preparation of ruthenium oxide-copper sulfide composite...

Embodiment 2

[0054] A ruthenium oxide-copper sulfide composite material, comprising 56% by weight of ruthenium oxide hydrate, 24% by weight of copper sulfide, 10% by weight of a conductive agent, and 10% by weight of a conductive agent. 10% binder composition.

[0055] Its preparation method comprises the following steps

[0056] (1) Preparation of copper sulfide nanomaterials;

[0057] Ultrasonically dissolve copper chloride hydrate in ethylene glycol, then add thiourea to the above reaction system, and stir for 0.5h to 1h;

[0058] After the above stirring, after hydrothermal reaction at 150°C-200°C for 8h-12h, suction filtration, water washing, alcohol washing, and drying at 150°C-200°C for 24h, the copper sulfide nanomaterial is obtained;

[0059](2) preparation of ruthenium trichloride solution;

[0060] Dissolving hydrated ruthenium trichloride in 40ml to 60ml of water to obtain a 10mg / ml to 20mg / ml ruthenium trichloride solution;

[0061] (3) Preparation of ruthenium oxide-coppe...

Embodiment 3

[0068] A ruthenium oxide-copper sulfide composite material is composed of 50% by weight of hydrated ruthenium oxide, 32% by weight of copper sulfide, 10% by weight of a conductive agent, and 10% by weight of a conductive agent. 8% binder composition.

[0069] Its preparation method comprises the following steps

[0070] (1) Preparation of copper sulfide nanomaterials;

[0071] Ultrasonically dissolve copper chloride hydrate in ethylene glycol, then add thiourea to the above reaction system, and stir for 0.5h to 1h;

[0072] After the above stirring, after hydrothermal reaction at 150°C-200°C for 8h-12h, suction filtration, water washing, alcohol washing, and drying at 150°C-200°C for 24h, the copper sulfide nanomaterial is obtained;

[0073] (2) preparation of ruthenium trichloride solution;

[0074] Dissolving hydrated ruthenium trichloride in 40ml-60ml water to obtain 10mg / m1-20mg / ml ruthenium trichloride solution;

[0075] (3) Preparation of ruthenium oxide-copper sulfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com