Cutting insert, cutting tool, and method for manufacturing cut product using cutting tool

一种切削镶刀、切削工具的技术,应用在铣削切削刀片、制造工具、刀夹的附件等方向,能够解决损伤切削镶刀、刀夹加工面、切屑堵塞、不能够舒畅地排出切屑等问题,达到减少切削阻力、刚性提高、优异切屑排出性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

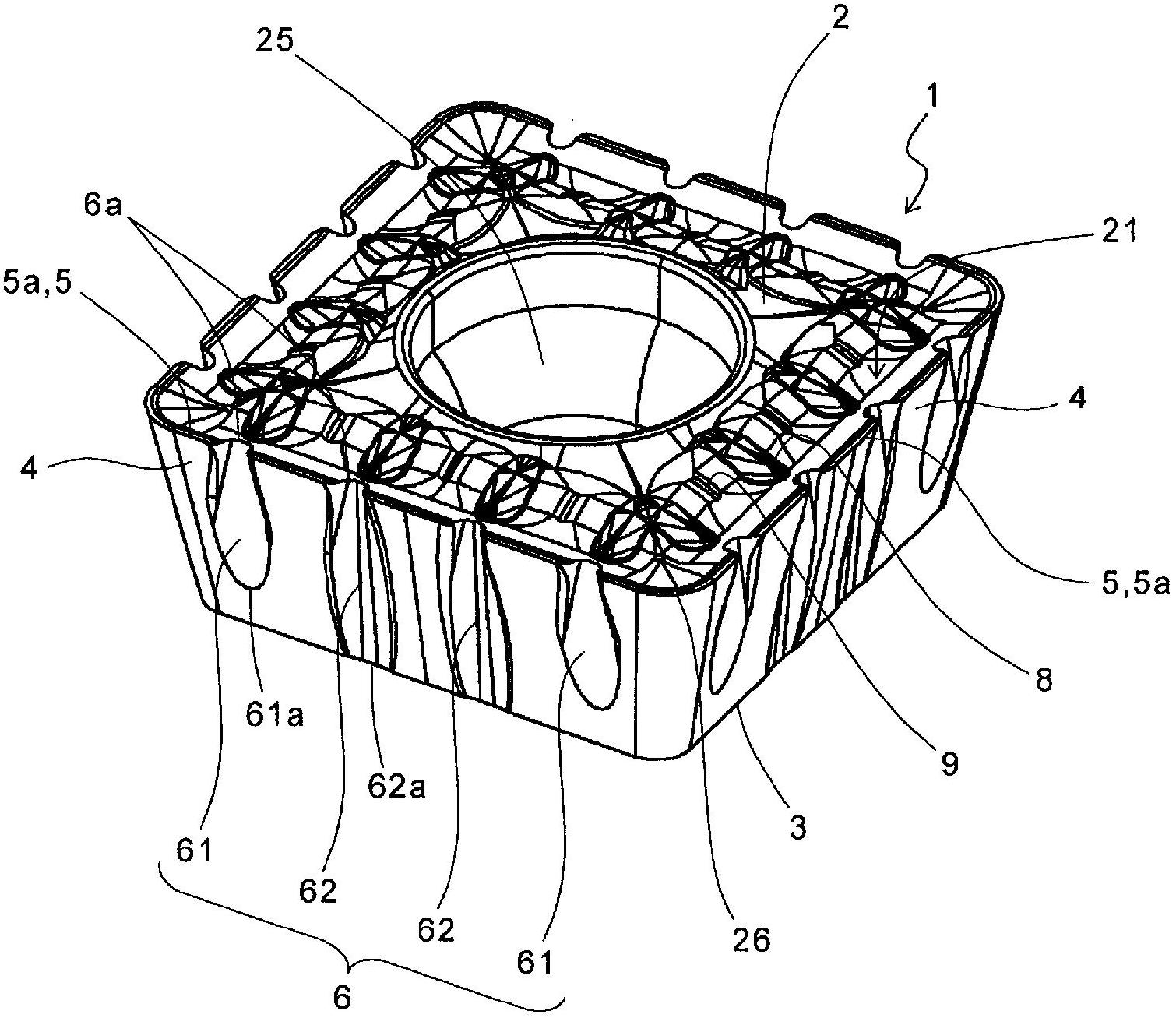

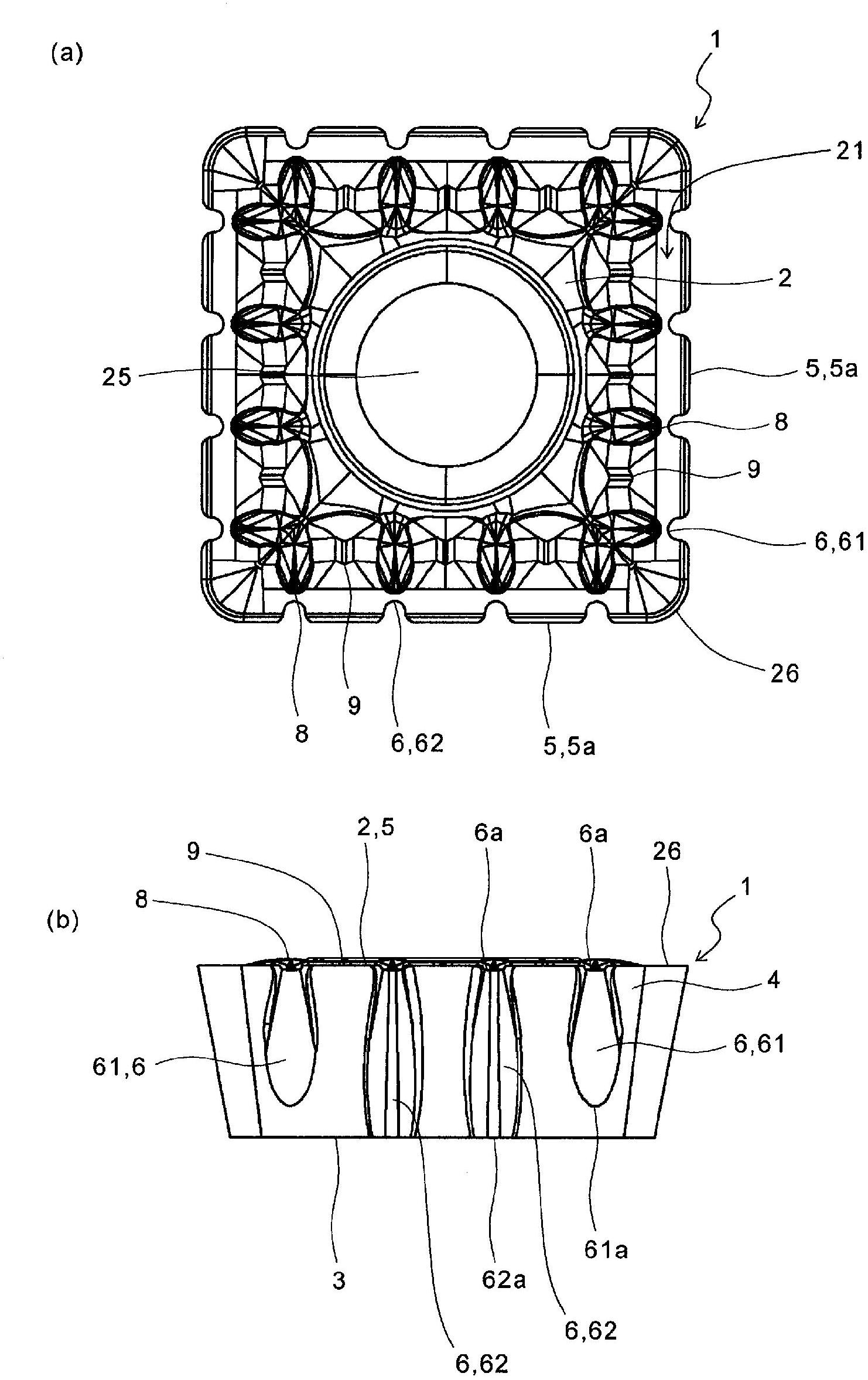

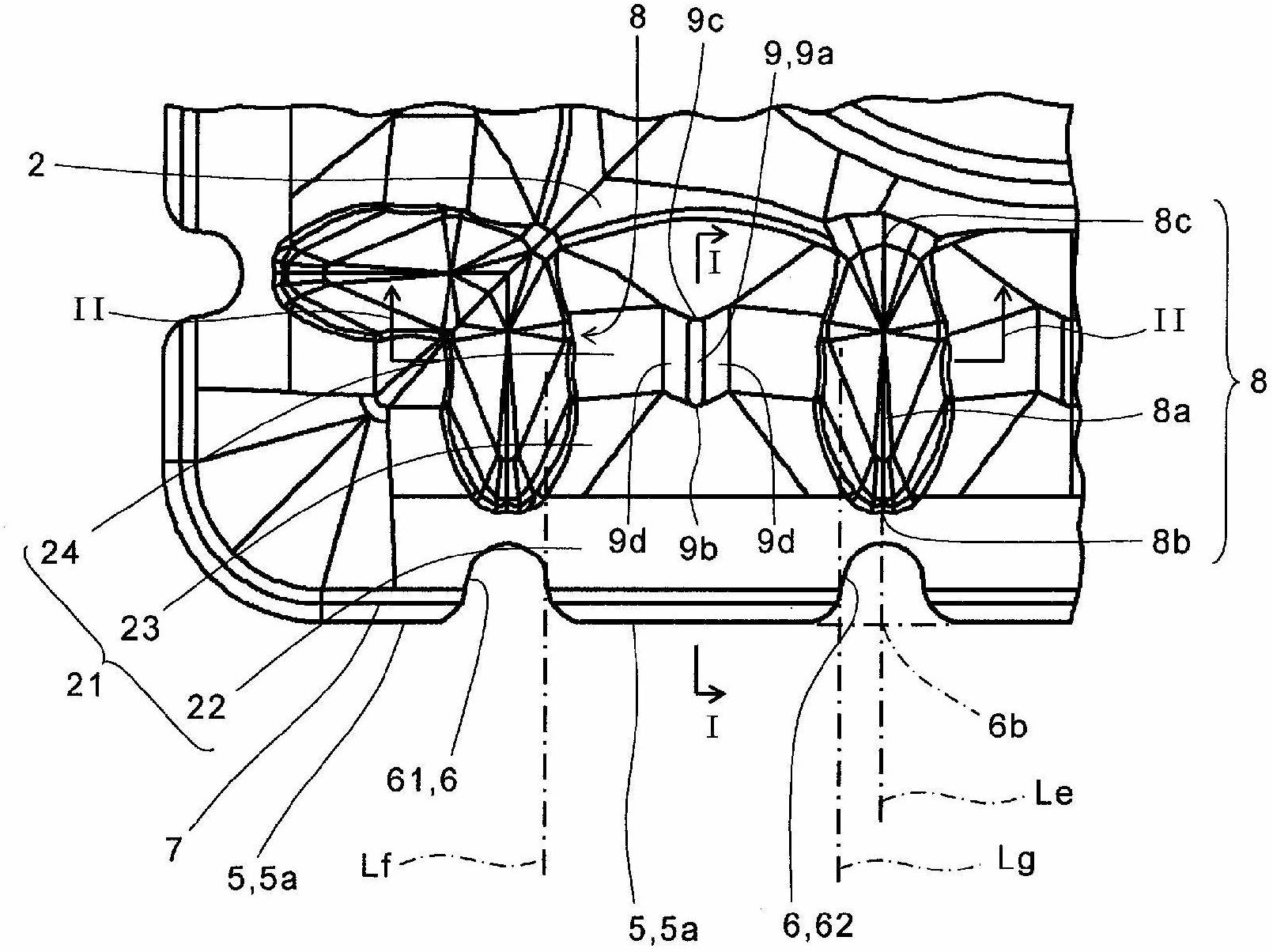

[0038] Below, refer to Figure 1 to Figure 5 The cutting insert (hereinafter referred to as "insert") according to the first embodiment of the present invention will be described in detail.

[0039] Such as figure 1As shown, the cutting insert 1 according to the present embodiment includes a main body having an upper surface 2, a lower surface 3, a side surface 4 located between the upper surface 2 and the lower surface 3, and a side surface 4 located between the upper surface 2 and the side surface 4. The cutting edge 5 of the intersection line.

[0040] The main body is composed of, for example, a member in which a film is coated on a sintered body such as cemented carbide, cermet, or ceramic. The film is for improving the wear resistance of the insert 1 . Examples of the film composition include titanium-based compounds such as titanium carbide, titanium nitride, and titanium carbonitride, or aluminum oxide. The film may be composed of at least one layer, and may be com...

no. 2 approach

[0079] Second, refer to Figure 6-10 The insert according to the second embodiment of the present invention will be described in detail. It should be noted that, in Figure 6-10 , for the above Figure 1~5 The same structural parts are marked with the same symbols and descriptions are omitted.

[0080] Such as Image 6 and Figure 7 As shown, the insert 31 according to the present embodiment includes a main body having an upper surface 32 , a lower surface 33 , and a side surface 34 . In the present embodiment, the main body has a quadrangular shape having four long sides and four corners with equal lengths.

[0081] In addition, in the insert 31, a cutting edge 35 is provided at the intersection of the upper surface 32 and the side surface 34, and as Figure 8 and Figure 9 As shown, the insert 31 is a so-called positive insert in which a positive relief angle θ3 is given to the side surface 34 . In the present embodiment, the relief angle θ3 is constant along the cut...

no. 3 approach

[0099] Second, refer to Figure 11 and Figure 12 An insert according to a third embodiment of the present invention will be described in detail. It should be noted that, in Figure 11 and Figure 12 , for the above Figure 1 to Figure 10 The same structural parts are marked with the same symbols and descriptions are omitted.

[0100] Such as Figure 11 As shown in (a), in the insert 31' according to this embodiment, the concave portion 36 is formed on the entire surface of the side surface 34, a plurality of divided cutting edges 35a are formed on the first side surface 34a, and a plurality of split cutting edges 35a are formed on the second side surface 34b. A plurality of divided cutting edges 35c are formed.

[0101] In this embodiment, three recesses 36a are formed on the first side surface 4a, and four recesses 36c are formed on the second side surface 34b. Therefore, the cutting edge 35 formed at the intersection of the first side surface 34a and the upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com