Liquefied natural gas filling pry

A technology of liquefied natural gas and liquid level, which is applied in the direction of gas/liquid distribution and storage, equipment loaded into pressure vessels, pipeline systems, etc., which can solve the problems of inability to establish LNG gasification stations, inability to pay fees in time, and inability to realize remote monitoring To achieve the effect of remote monitoring, excellent evaporation rate index and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific examples.

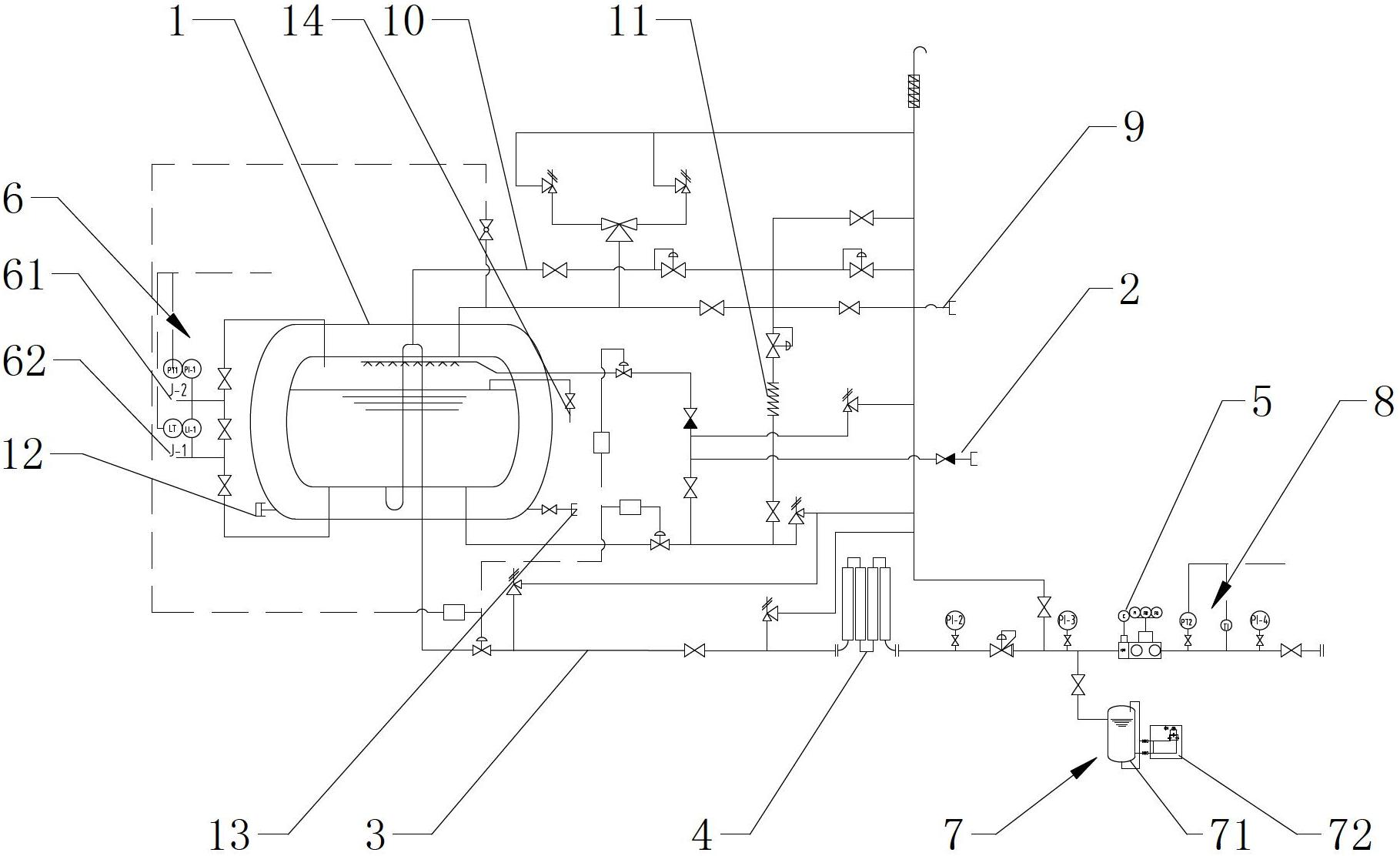

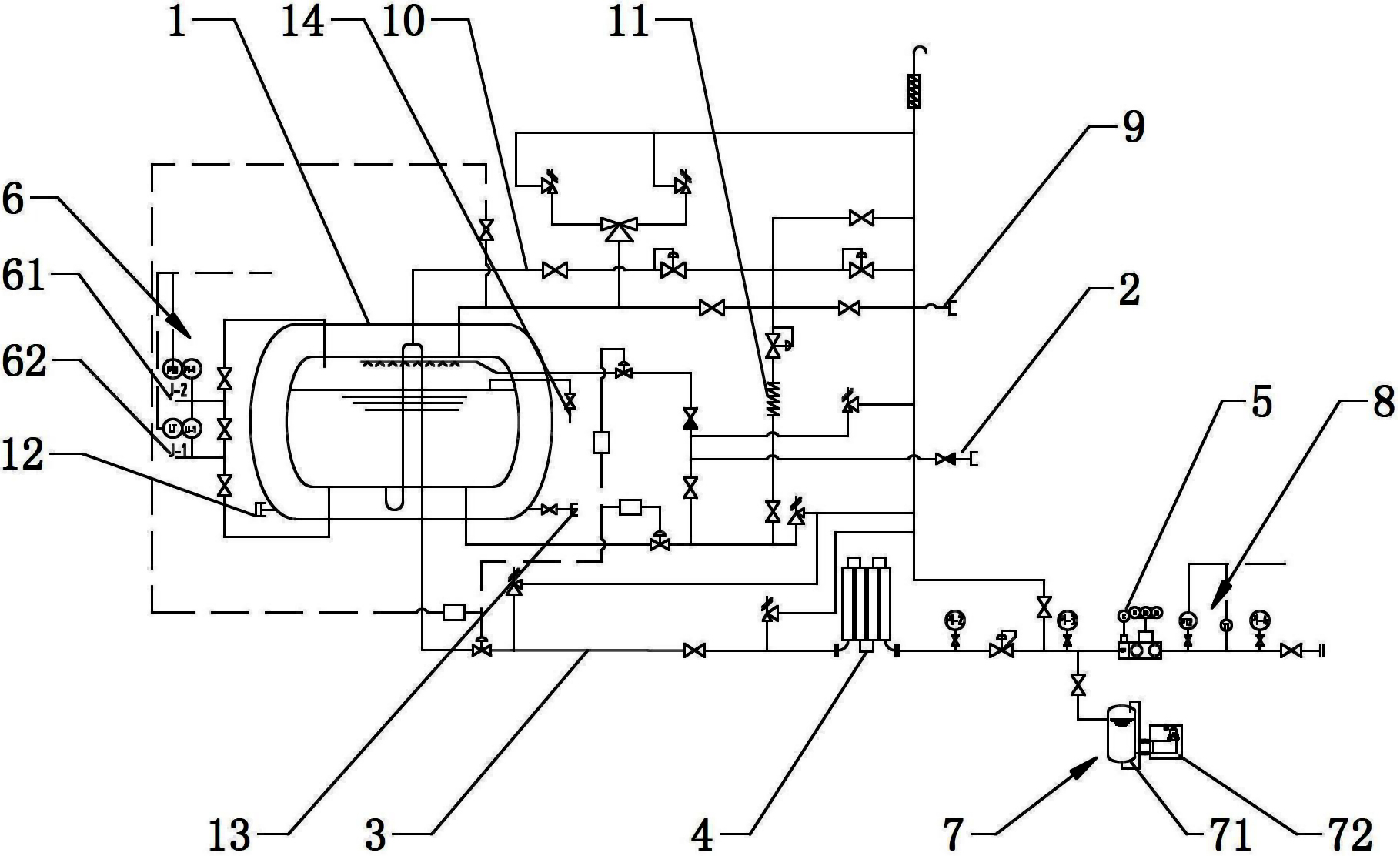

[0030] Such as figure 1 As shown, the liquefied natural gas refueling skid includes a storage tank 1, the storage tank 1 includes an inner tank body and an outer tank body, and a heat-insulating and radiation-proof heat-insulating material is provided in the cavity between the inner tank body and the outer tank body, and the cavity It is connected with the vacuum port 12, and the outer tank body is provided with a vacuum test port 13 communicating with the cavity. The storage tank 1 is provided with an overflow pipeline 14, and the overflow pipeline 14 is provided with an overflow valve. The storage tank 1 is provided with an input port and an exhaust port, the input port is connected to the liquid filling pipeline 2, and the exhaust port is connected to the pressure regulating pipeline system. The pressure regulating system includes a supercharger 11 and the exhaust port of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com