L-CNG (Liquid-Compressed Natural Gas) skid-mounted device without energy consumption

A technology of L-CNG without energy consumption, applied in the method of container discharge, equipment discharged from pressure vessels, pressure vessels, etc., can solve the problem of high energy consumption, and achieve the effect of saving energy and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

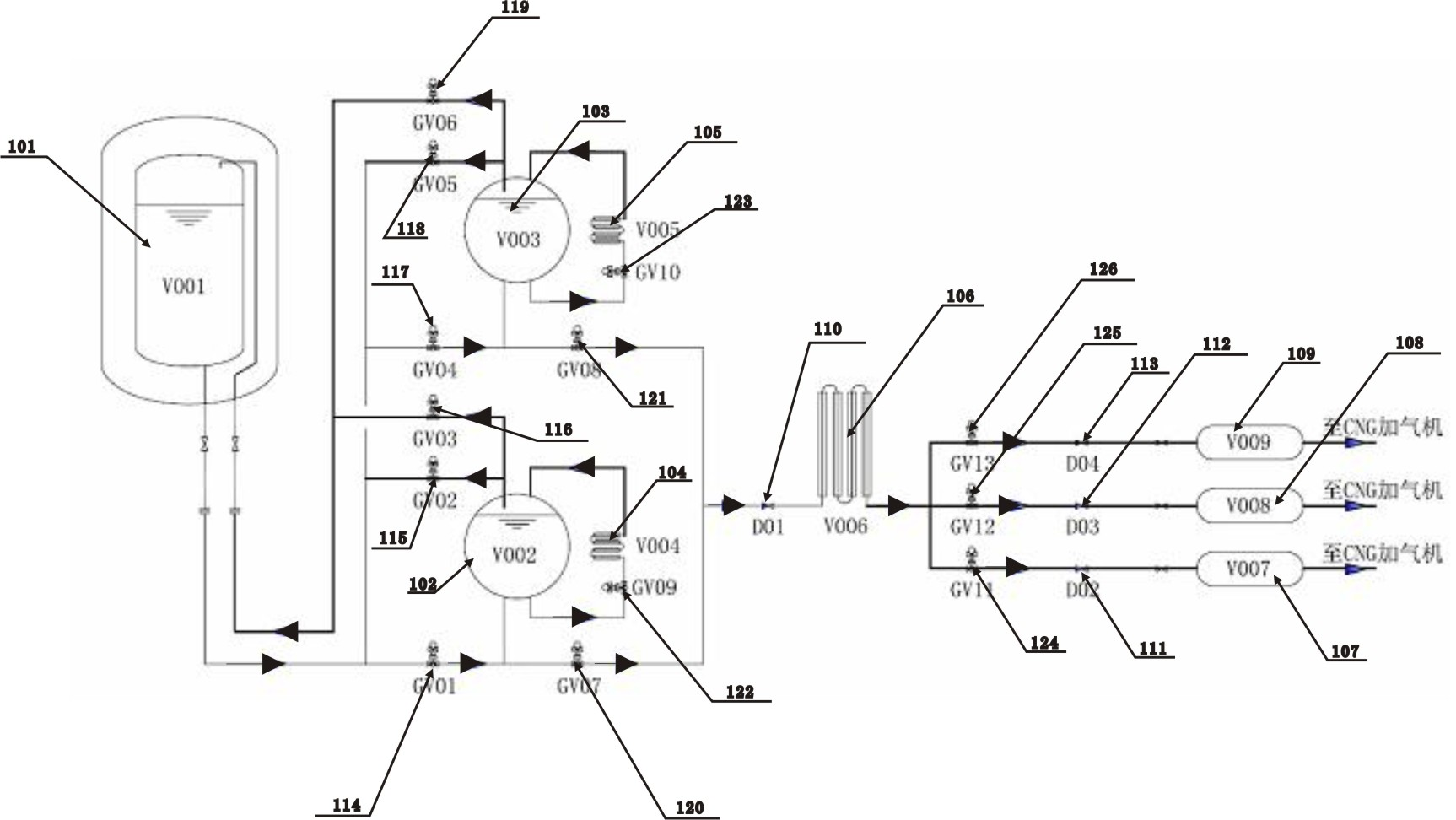

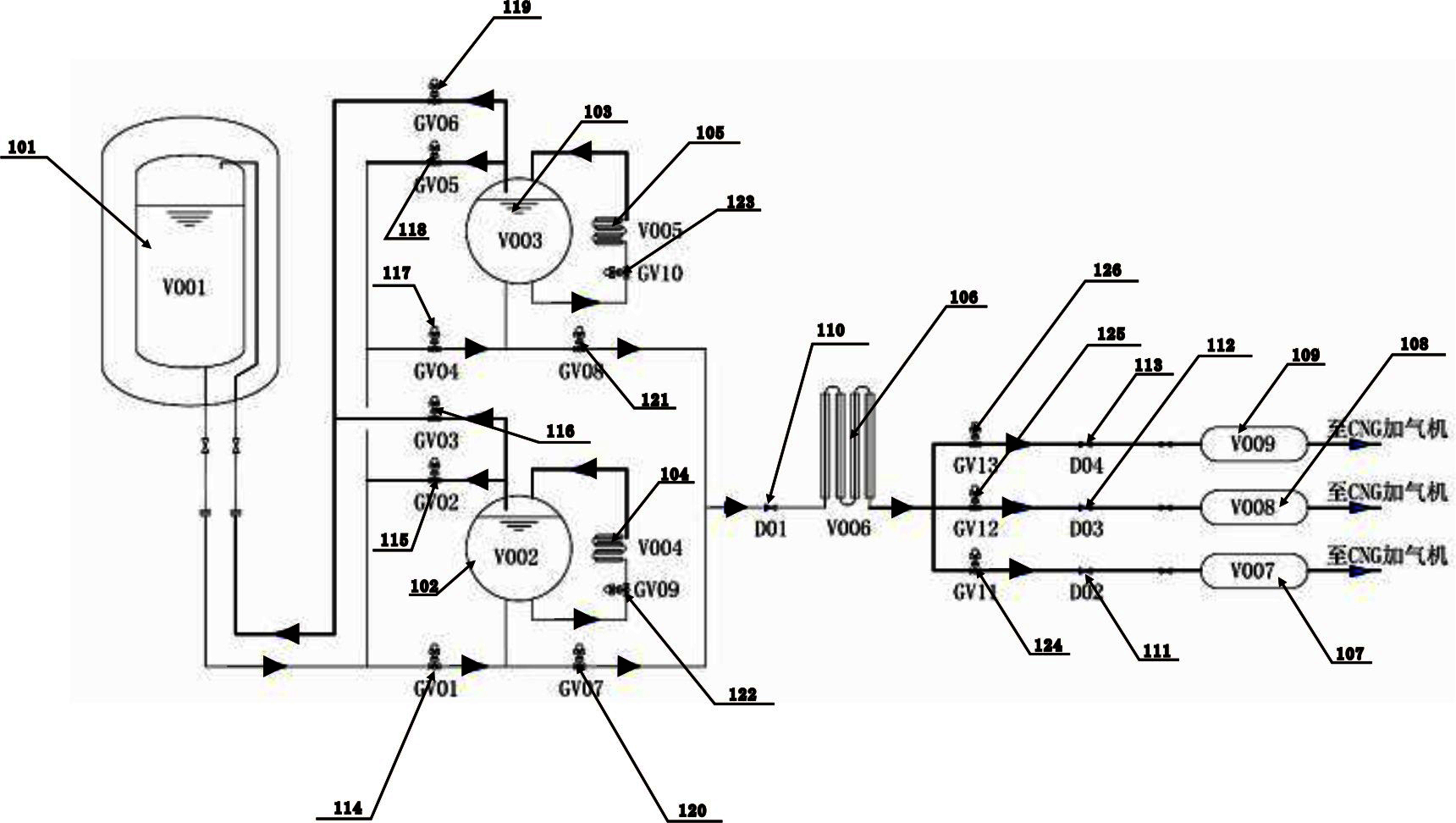

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

[0026] The invention provides a non-energy-consuming L-CNG skid-mounted device, such as figure 1 Shown: There is a low temperature insulation storage tank V001101: It adopts a double-layer insulation structure and is used to store LNG on the gas station. There are low-temperature and high-pressure spherical storage tanks V002 102 and low-temperature and high-pressure spherical storage tanks V003 103: used for temporary storage of LNG. There are LNG high-pressure booster V004 104 and LNG high-pressure booster V005 105: used to absorb heat from the air and transfer the heat to the internal LNG, so that the LNG is heated and gasified. After gasification, the high-pressure spherical storage tank will Pressure rises. Equipped with LNG high-pressure air-temperature vaporizer V006 106: it is used to absorb heat from the air, transfer the heat to the internal LNG, let the LNG be hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com