Silicon carbide composite tube for zinc-plating spiral hexsteel

A tortoise shell mesh silicon carbide and composite pipe technology is applied in the field of composite pipes, which can solve the problems that the construction quality is easily affected by human factors, the coating of corundum ceramic patches is easy to crack, and the thermal shock resistance of corundum ceramic patches is poor. Good thermal shock resistance, light specific gravity, and the effect of enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

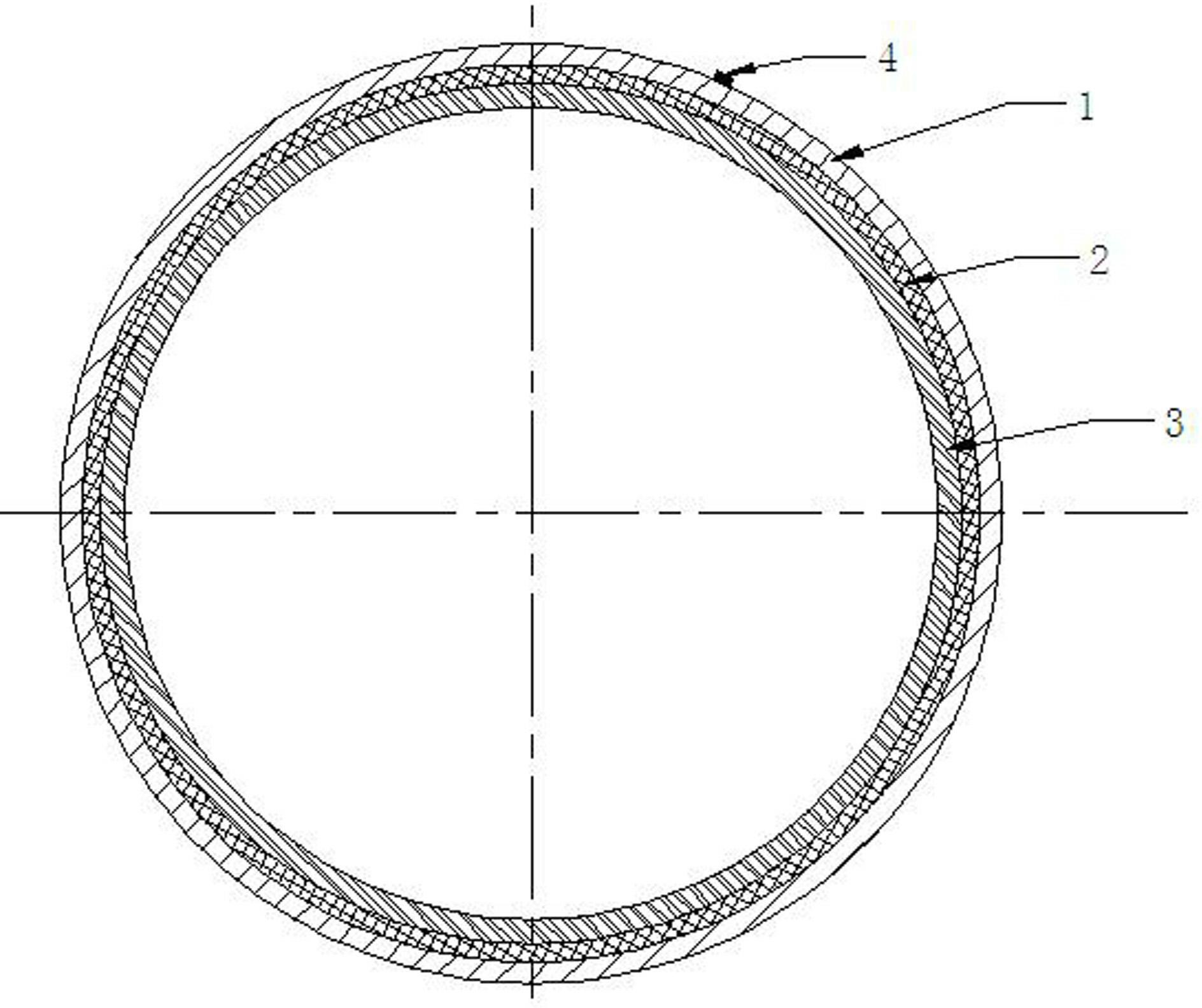

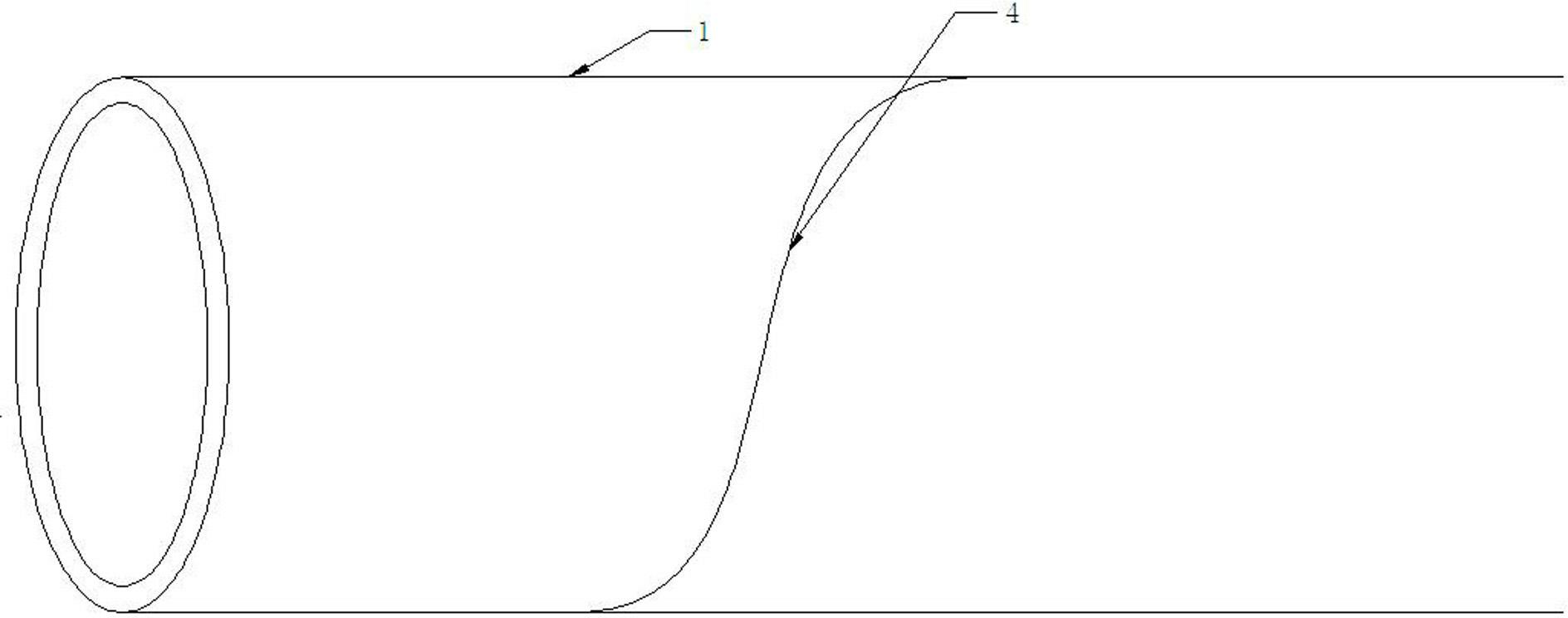

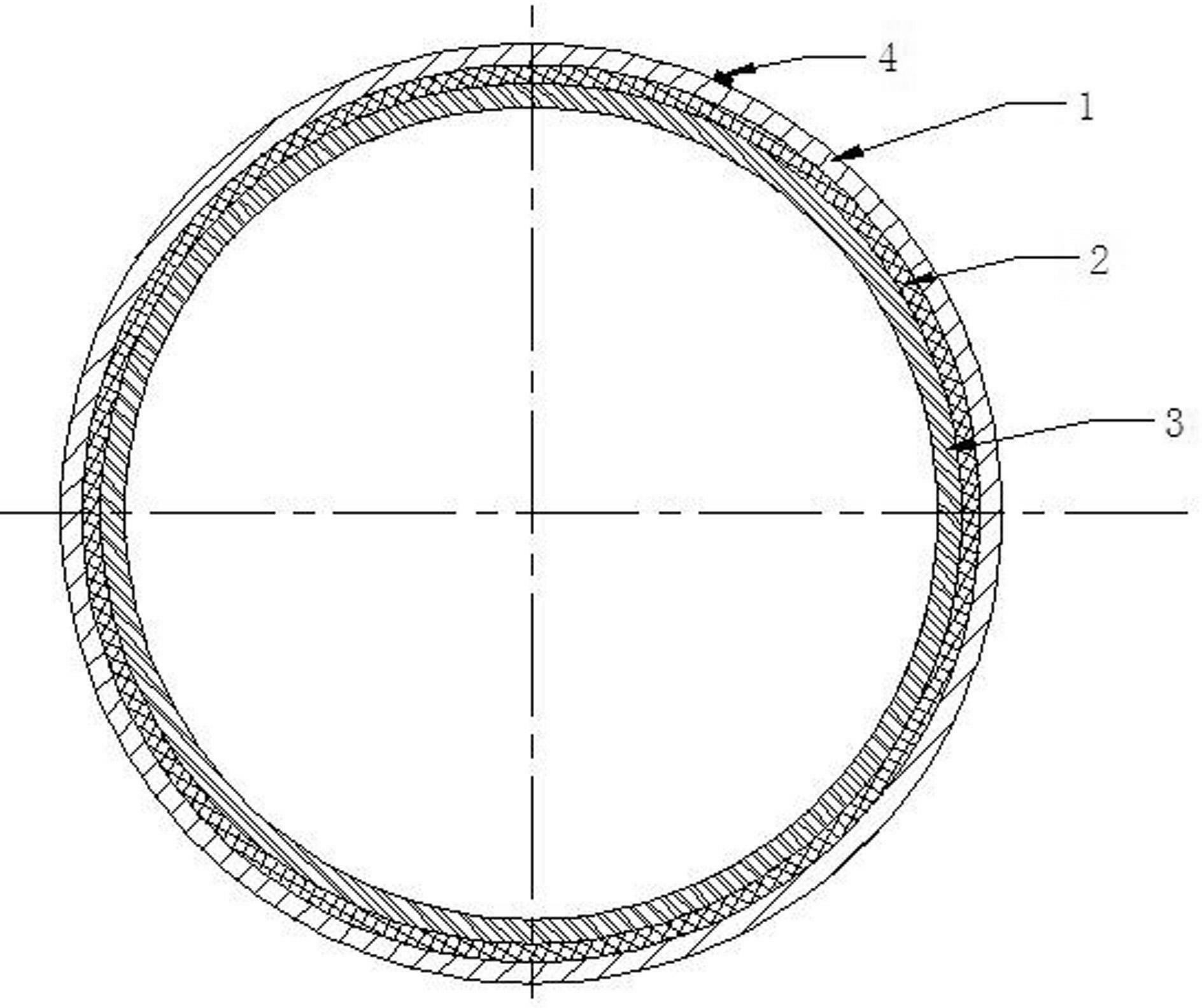

[0010] Such as figure 1 As shown, the galvanized spiral tortoise shell mesh silicon carbide composite pipe is composed of light galvanized spiral reinforced steel pipe 1, tortoise shell mesh 2, and silicon carbide ceramics 3 from outside to inside. Clawed tortoise shell mesh 2 (the grid is in a honeycomb shape) is welded to the inner wall of light galvanized spiral reinforced steel pipe 1, the silicon carbide ceramic 3 and the adhesive are fully stirred evenly, and then filled in the welded tortoise shell mesh 2, Ensure that each grid is filled with wear-resistant materials, and the two claws protruding into the silicon carbide ceramic 3 firmly anchor the silicon carbide ceramic 3 to form a strong wear-resistant layer. Welding of tortoise shell mesh 2 requires four grids with more than two solder joints (one solder joint each with a horizontal and vertical length of 10cm). The outer wall of the spiral reinforced steel pipe 1 is attached with a crest spiral reinforcement rib 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com