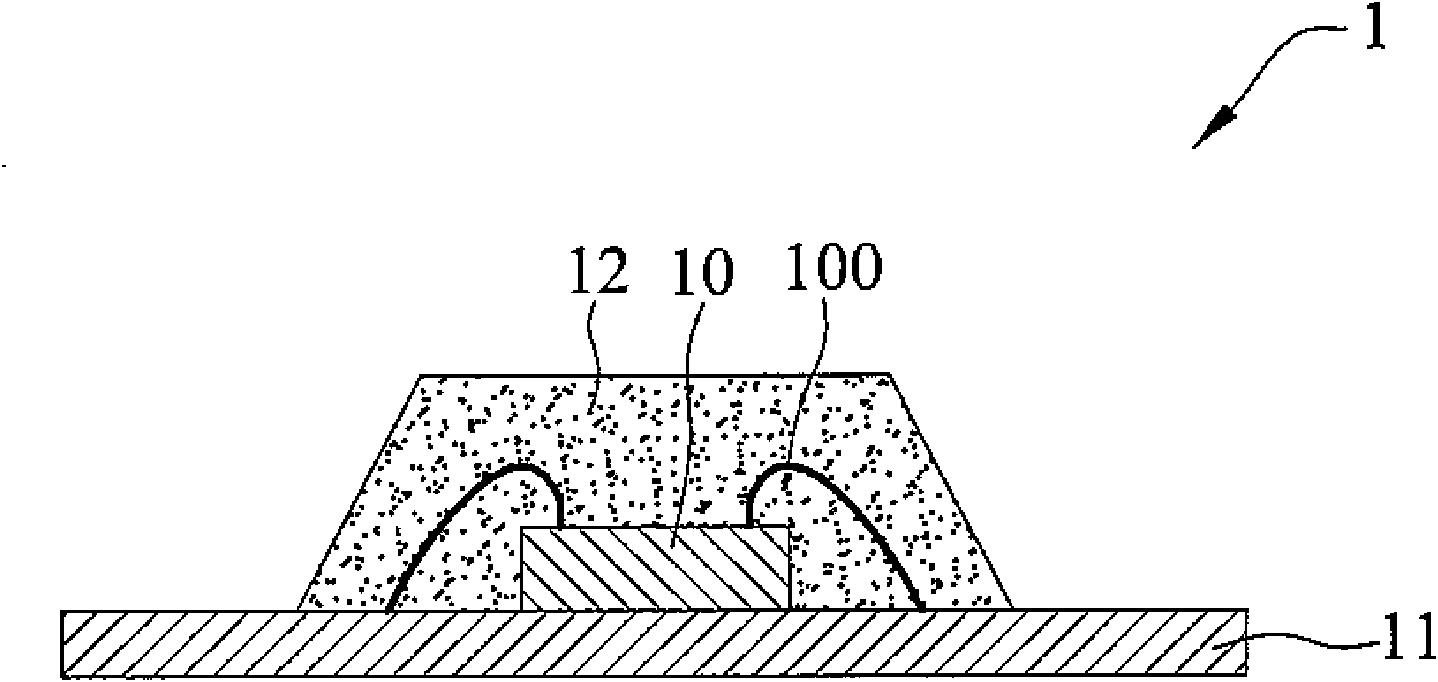

III-V solar battery packaging part and manufacturing method thereof

A solar cell, III-V technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as inability to bend or poor bending rate, inability to use arc-shaped products, inability to meet miniaturization, etc., to reduce weight. and the effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The implementation of the present invention is described below through specific specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

[0046] Figure 2A to Figure 2C It is the preparation method of III-V group solar cell encapsulation member 2 of the present invention.

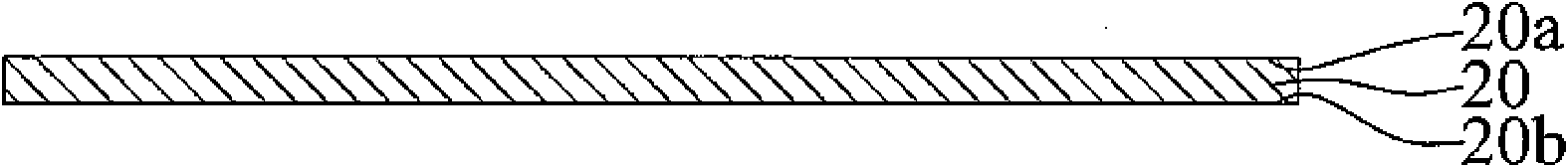

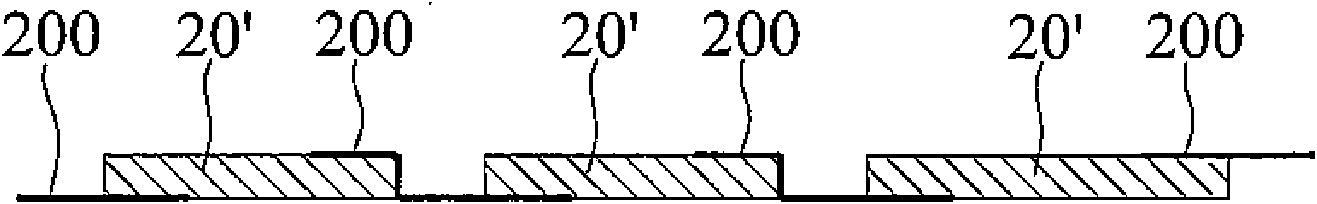

[0047] Such as Figure 2A As shown, firstly, a solar cell 20 with opposite first side 20a and second side 20b is provided; in another embodiment, as Figure 2A ′, a plurality of solar cells 20 ′ can be connected in series through conductive elements such as bonding wires 200 , or can be electrically connected in parallel (not shown in the figure).

[0048] Such as Figure 2B As shown, next, a first insulating layer 21a and a second insulating layer 21b are respectively formed on the first side 20a and the second side 20b of the solar cell 20, and the first and second insulating lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com