Preparation method for successively producing yak bone marrow oil and ultramicro polypeptide bone calcium powder once

A technology of yak bone marrow and peptide bone calcium powder, which is applied in the field of one-time continuous production of yak bone oil and ultrafine polypeptide bone calcium powder, and can solve the problem that the preparation methods of yak bone oil and ultrafine polypeptide bone calcium powder have not been reported. problems, to achieve the effect of increasing added value, improving taste and improving digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

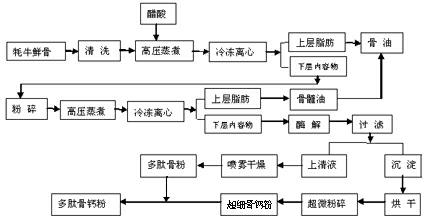

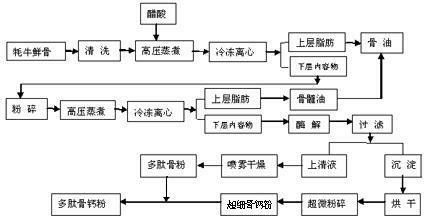

[0021] The preparation method of one-time continuous production of yak bone marrow oil and ultrafine polypeptide bone calcium powder of the present invention, the steps of the method are as follows:

[0022] ⑴. Cleaning: Wash the fresh skeleton with clean water, and blanch it in boiling water for 5 minutes to remove the blood, and then wash it with clean water, which meets the hygienic requirements;

[0023] ⑵. High-pressure cooking: Put the cleaned and crushed bones into a high-pressure cooking pot, add water according to the material-liquid ratio of 1:6 (w / v), and cook for 40 minutes at 0.2-0.3MPa, 105-110°C , in order to soften the bones and increase the free calcium content, a certain amount of acetic acid is added during cooking to make the pH reach 4.5-5;

[0024] ⑶. Separation: After refrigerated and centrifuged, remove the upper layer of fat as bone oil;

[0025] ⑷. Crushing and secondary high-pressure cooking: After filtering the contents of the lower layer, separate...

Embodiment 1

[0032] Take 200g of yak bone raw material, clean it, and blanch it in boiling water for 5 minutes to remove the blood, then wash it with clean water, grind it roughly, put it into a high-pressure cooking pot, and add water according to the ratio of material to liquid at 1:6 (w / v) , cook at 0.2-0.3MPa, 105-110°C for 40 minutes, and add a certain amount of acetic acid to make the pH 5; after cooking, perform refrigerated centrifugation, take the upper layer of fat as bone oil; filter the contents of the lower layer, Separate the bone and meat, crush it again, and continue to cook at 0.2-0.3MPa, 105-110°C for 30 minutes. After the same freeze and centrifugation, collect the upper layer of fat and combine it with the bone oil collected for the first time to obtain the bone marrow oil product. Then carry out enzymolysis of the above-mentioned lower layer content, the enzyme used is papain, the enzymolysis conditions are: enzymolysis temperature is 58°C, pH is 6, enzyme dosage is 960...

Embodiment 2

[0034]Take 500g of yak bone raw material, clean it, and blanch it in boiling water for 5 minutes to remove blood, then wash it with clean water, grind it roughly, put it into a high-pressure cooking pot, and add water according to the ratio of material to liquid at 1:6 (w / v) , cook at 0.2-0.3MPa, 105-110°C for 40 minutes, and add a certain amount of acetic acid to make the pH 5; after cooking, perform refrigerated centrifugation, take the upper layer of fat as bone oil; filter the contents of the lower layer, Separate the bone and meat, crush it again, and continue to cook at 0.2-0.3MPa, 105-110°C for 30 minutes. After the same freeze and centrifugation, collect the upper layer of fat and combine it with the bone oil collected for the first time to obtain the bone marrow oil product. Then carry out enzymolysis of the above-mentioned lower layer content, the enzyme used is papain, the conditions of enzymolysis are: the enzymolysis temperature is 60°C, the pH is 5.7, the enzyme d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com