Electric kettle and working method thereof

A technology for an electric kettle and a working method, which is applied in the direction of timing control of ignition mechanisms, cooking utensils, household utensils, etc., can solve problems such as unfavorable cleaning, inability to reach boiling temperature, inconvenient cleaning, etc., so as to reduce mental burden and protect personal safety. , the effect of improving life efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

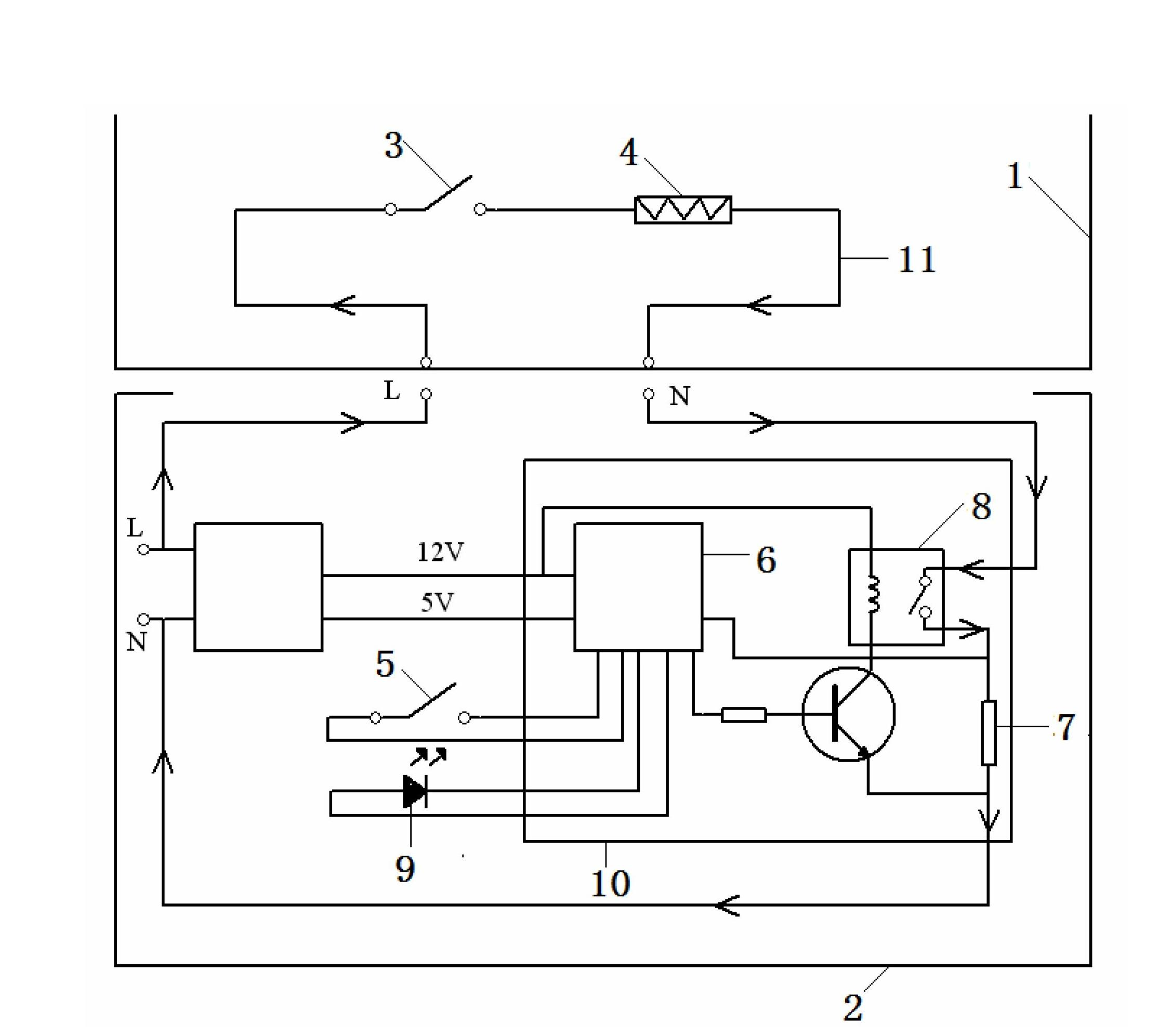

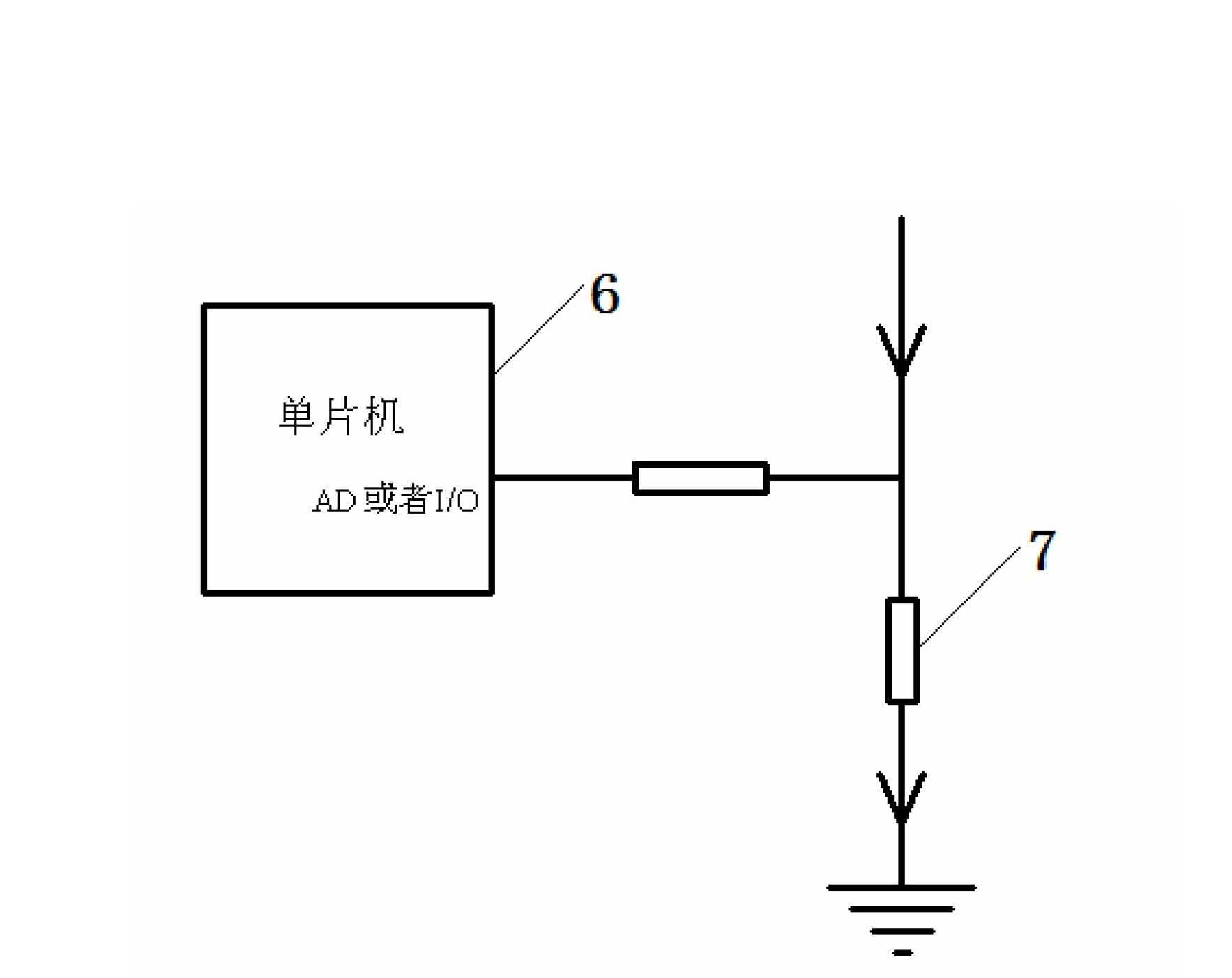

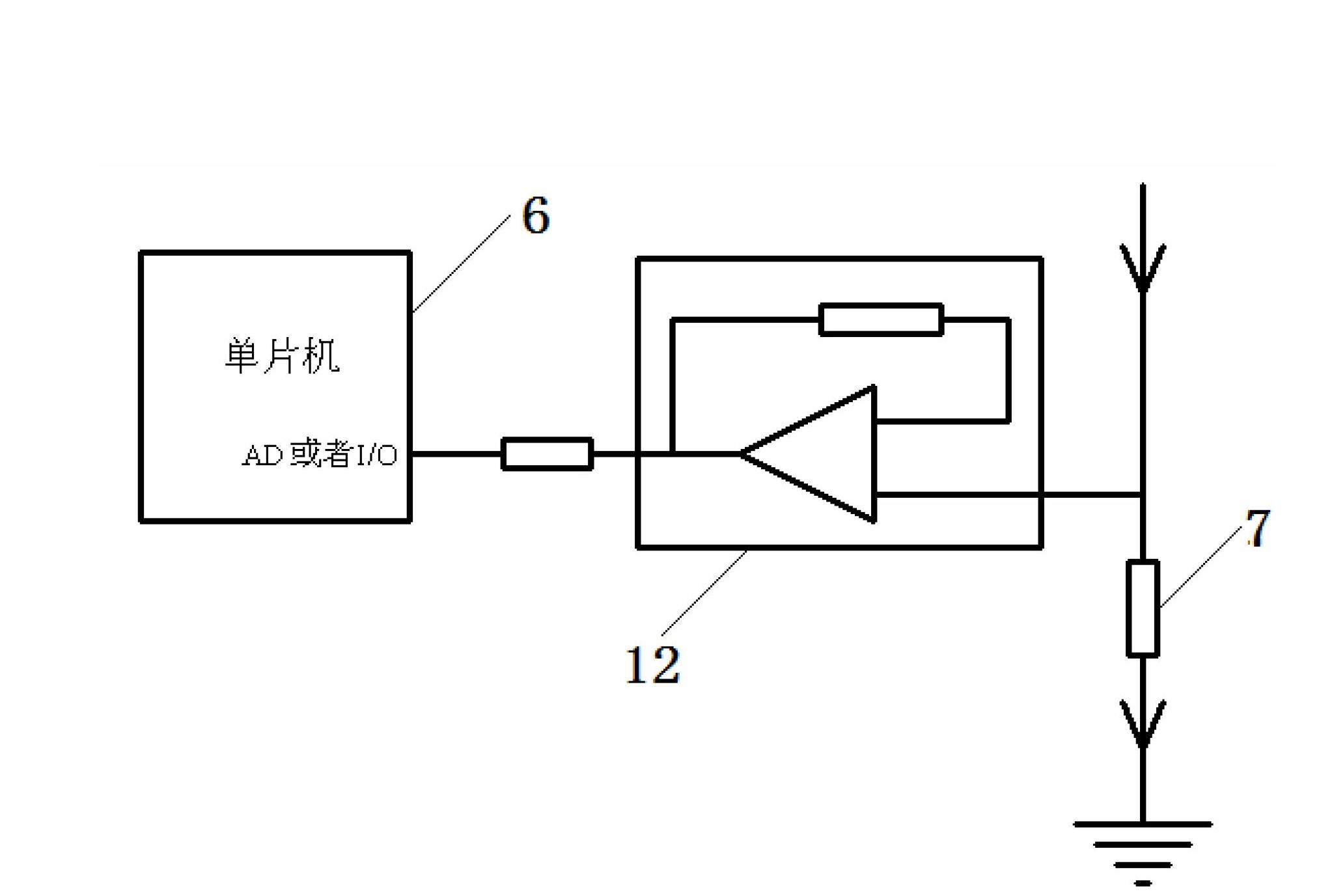

[0035] refer to figure 1 , an electric kettle, comprising a body 1 provided with an upper coupler, a base assembly 2 provided with a lower coupler, a control circuit 10 disposed in the base assembly 2 and a user operating device 5, the body 1 and The base assembly 2 is connected by an upper and a lower coupler and forms a heating circuit 11 between them, the body 1 includes a container forming a liquid holding chamber, the bottom of the container is provided with an electric heating element 4, and the bottom of the container is A bimetal thermostat 3 is arranged on the lower surface of the wall, the bimetal thermostat 3 and the electric heating element 4 are connected in series in the heating circuit 11, and the control circuit 10 includes a current detection unit 7. The heating circuit 11 further includes a relay 8 communicating with the control circuit 10, and the control circuit 10 controls the conduction or switching of the relay 8 according to the detected on-off signal o...

Embodiment 2

[0043] refer to Figure 7 , the working method of the electric kettle described in the above-mentioned invention comprises the following working steps:

[0044] (1) Turn on the power supply, and the control circuit 10 is in a standby state;

[0045] (2) Press the user operation device 5, after the single-chip microcomputer detects the trigger signal from the user operation device 5 to make the heating circuit 11 conduction, the control circuit 10 enters the working state, and the single-chip microcomputer 6 sends a conduction command to the relay 8, so that The heating circuit 11 is turned on, and the single-chip microcomputer 6 starts to detect whether there is a current circulation in the heating circuit 11;

[0046] (3) If it is detected that there is current in the heating circuit 11, the single-chip microcomputer 6 sends a conduction command to keep the relay 8 on, and the heating circuit 11 remains on; if it detects that there is no current in the heating circuit 11, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com