Precision combined electrochemical machining method

A processing method and composite processing technology, which is applied in the field of precision composite electrolytic machining, can solve problems such as insufficient electrolytic machining accuracy, and achieve the effect of improving electrolytic machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

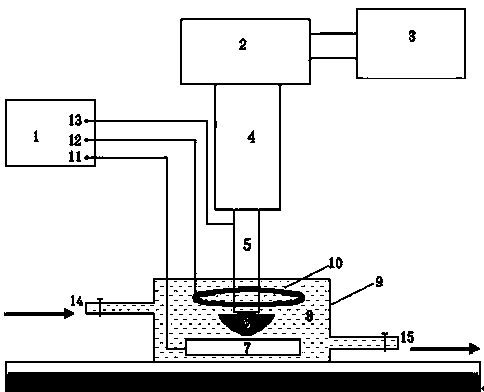

[0036] Such as figure 1 As shown, the composite electrolytic processing device used in the present invention includes a template 6, a fixing frame 5, a driving device 2, an information processing computer 3, and an electrochemical system. The template 6 is fixed on the lower part of the fixed frame 5, the upper part of the fixed frame is connected to the vertical drive shaft 4 of the driving device, and the driving device 2 is connected to the information processing computer 3. The drive device is provided with a drive controller capable of stepping in three directions of X, Y, and Z to control the relative distance between the template 6 and the workpiece 7 and the processing position on the XY plane. The electrochemical system includes a working power source 1 , an electrolyte solution 8 , a receiving electrode 10 and an electrolytic cell 9 . The working power supply is provided with working electrode terminal 11, counter electrode (ie auxiliary electrode) terminal 13, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com