Surface emitting laser packaging fixture

A surface-emitting laser and clamping technology, which is applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of easy-to-deviate tube shells, poor fixation of heat sinks, and poor mobility, so as to improve efficiency and improve The effect of fixed efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

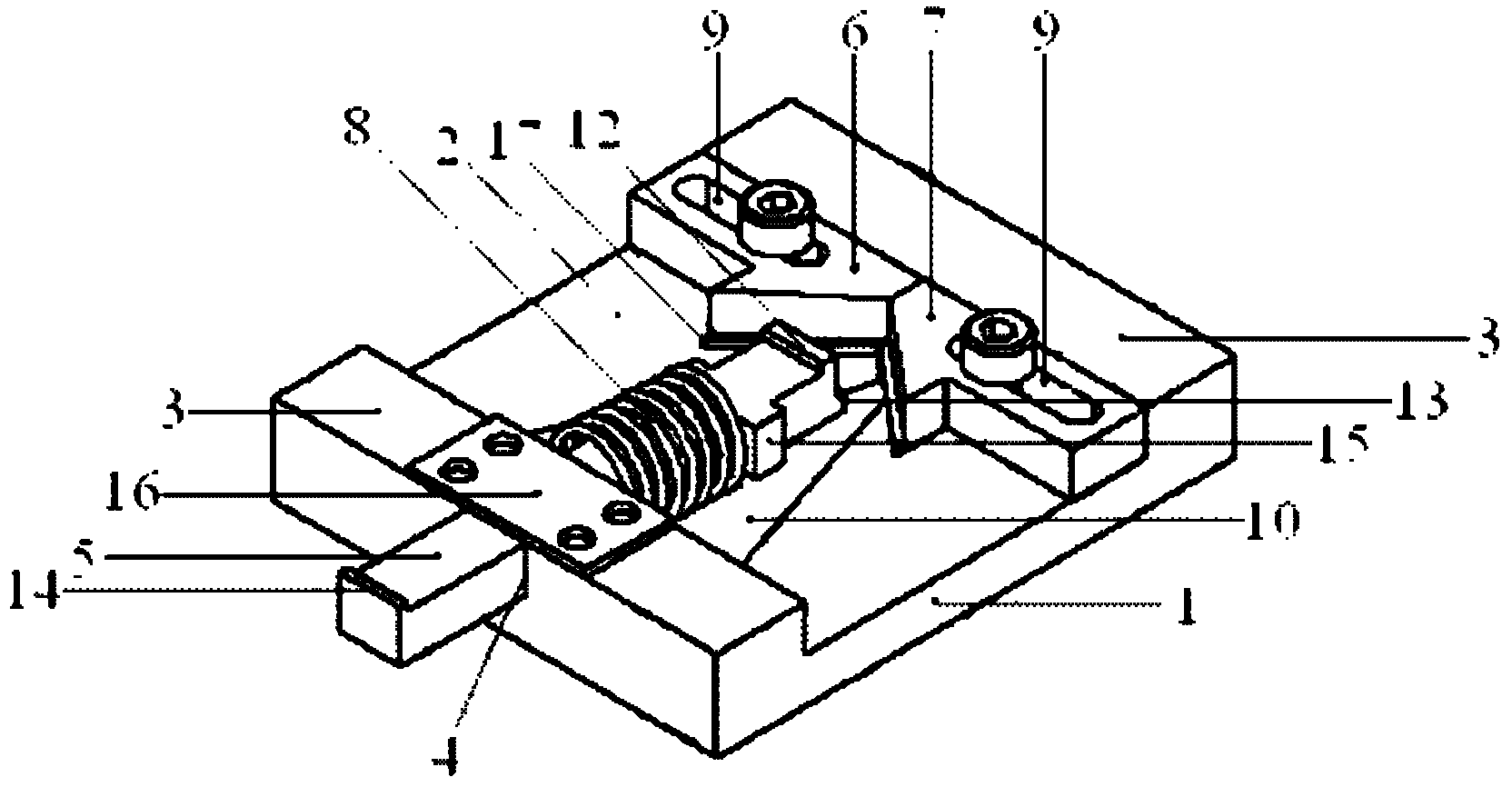

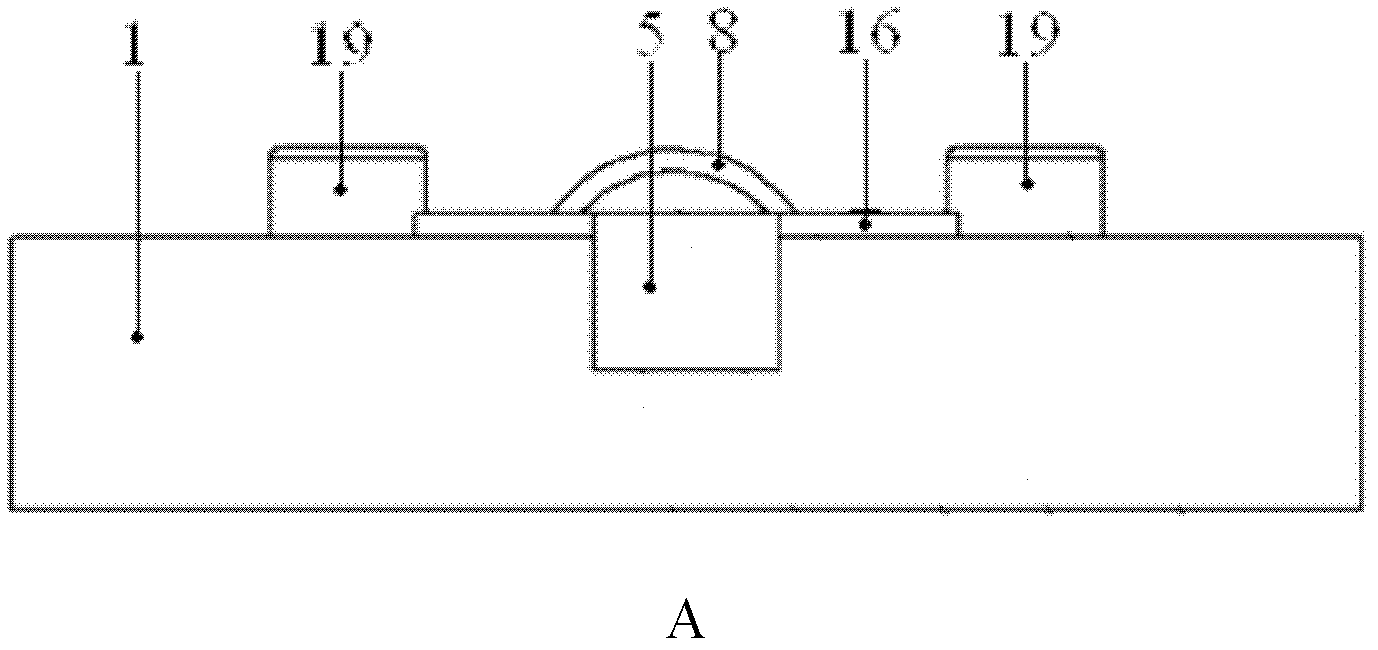

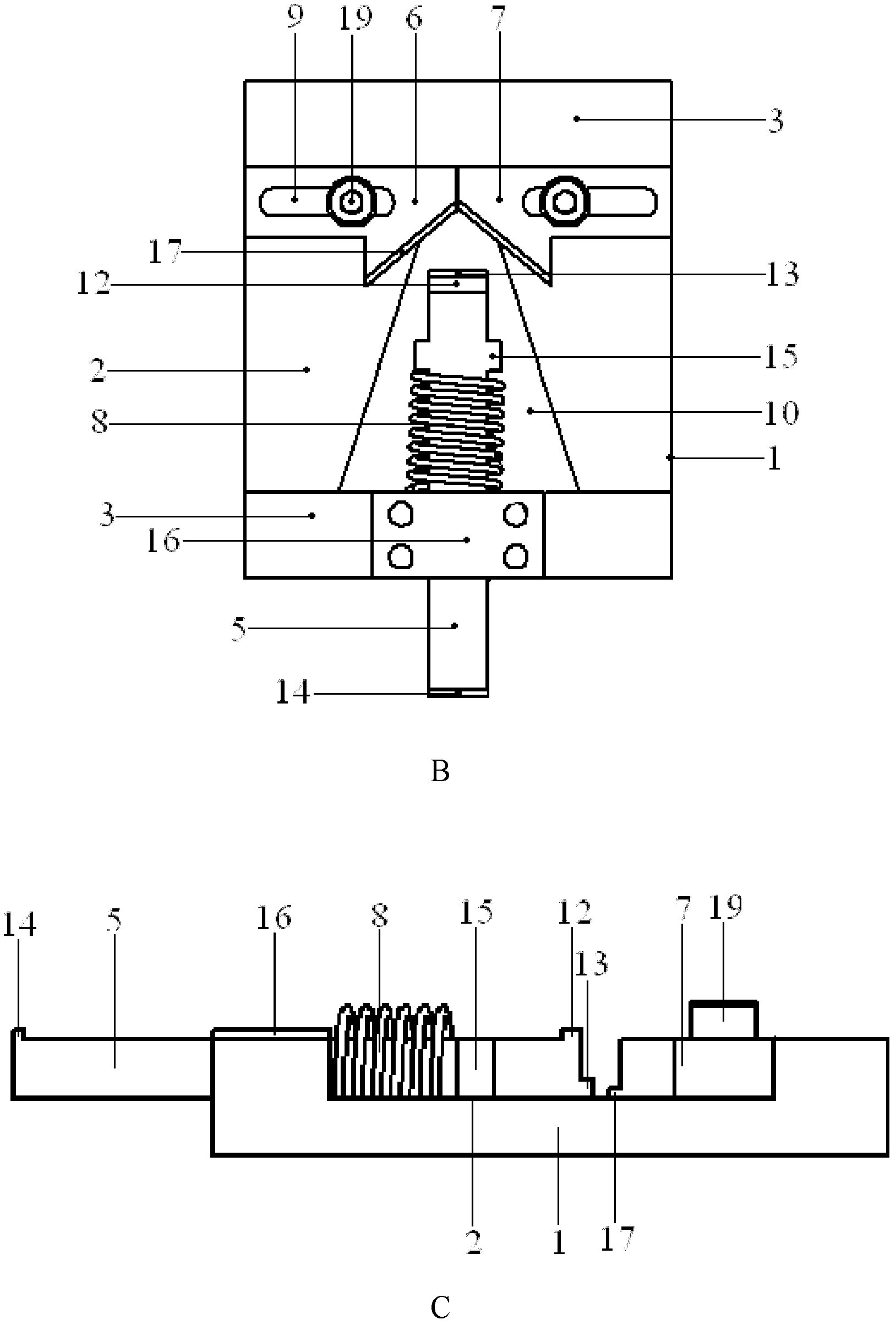

[0017] Specific implementation mode 1. Combination figure 1 Describe this embodiment, as shown in the figure, the surface-emitting laser packaging fixture of the present invention includes a fixture body 1, a rectangular sinking structure 2 is arranged in the middle of the fixture body 1, and raised structures 3 of the same width are respectively arranged at both ends, There is a sliding groove 4 in the middle of the protruding structure 3 at one end, which is characterized in that it also includes a push rod 5, a left tightening part 6 and a right tightening part 7. The push rod 5 passes through the sliding groove 4 and is movably connected with the clamp main body 1, and the spring 8 is inserted into the ejector rod 5, and the left tightening part 6 and the right tightening part 7 are respectively provided with length adjustment grooves 9, and the positions of the left tightening part 6 and the right tightening part 7 in the length adjustment groove 9 are aligned with the pos...

specific Embodiment approach 2

[0024] Embodiment 2. The difference between this embodiment and Embodiment 1 is that this embodiment is a specific example of Embodiment 1.

[0025] The surface-emitting laser packaging fixture of the present invention is suitable for packaging and welding the surface-emitting laser on the shell or heat sink. The diameter of the shell or heat sink is required to be 5.4mm, the height is 12mm, and the size of the surface-emitting laser is 1mm×1mm.

[0026] The fixture main body 1, ejector rod 5, left tightening part 6 and right tightening part 7 of the surface emitting laser packaging fixture of the present invention are all made of aluminum material, and the shape of the above-mentioned parts is processed by a wire cutting method, and the above-mentioned parts are polished by a machine. Polish the surface, and then use ultrasonic cleaning and drying to form.

[0027] The fixture main body 1 is an axisymmetric structure, the length, width and height of the fixture main body 1 ar...

specific Embodiment approach 3

[0030] Embodiment 3. The difference between this embodiment and Embodiment 1 is that this embodiment is a specific working process of Embodiment 1.

[0031] combine Figure 7 To illustrate this embodiment, when the surface-emitting laser packaging fixture of the present invention is working, the left tightening component 6 and the right tightening component are adjusted by adjusting the positions of the screws 19 on the left tightening component 6 and the right tightening component 7 in the length adjustment groove 9. The distance between 7 is increased to an appropriate width, slide the ejector rod 5, so that the front desk 13 on the ejector rod 5 is separated from the left tightening part 6 and the right tightening part 7 by a suitable distance, and the base of the TO-46 tube shell 18 is placed on the left tightening On the protruding platform 17 of the component 6 and the right tightening component 7, use the pressure of the spring 8 to reset the ejector rod 5 and fix it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com