Gas drive type underwater disconnecting device

A technology of pneumatic drive and release device, which is applied in the directions of underwater operation equipment, transportation and packaging, ships, etc., can solve the problems of inapplicability of underwater electric manipulators, etc., and achieve the effects of light weight, guaranteed reliability and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

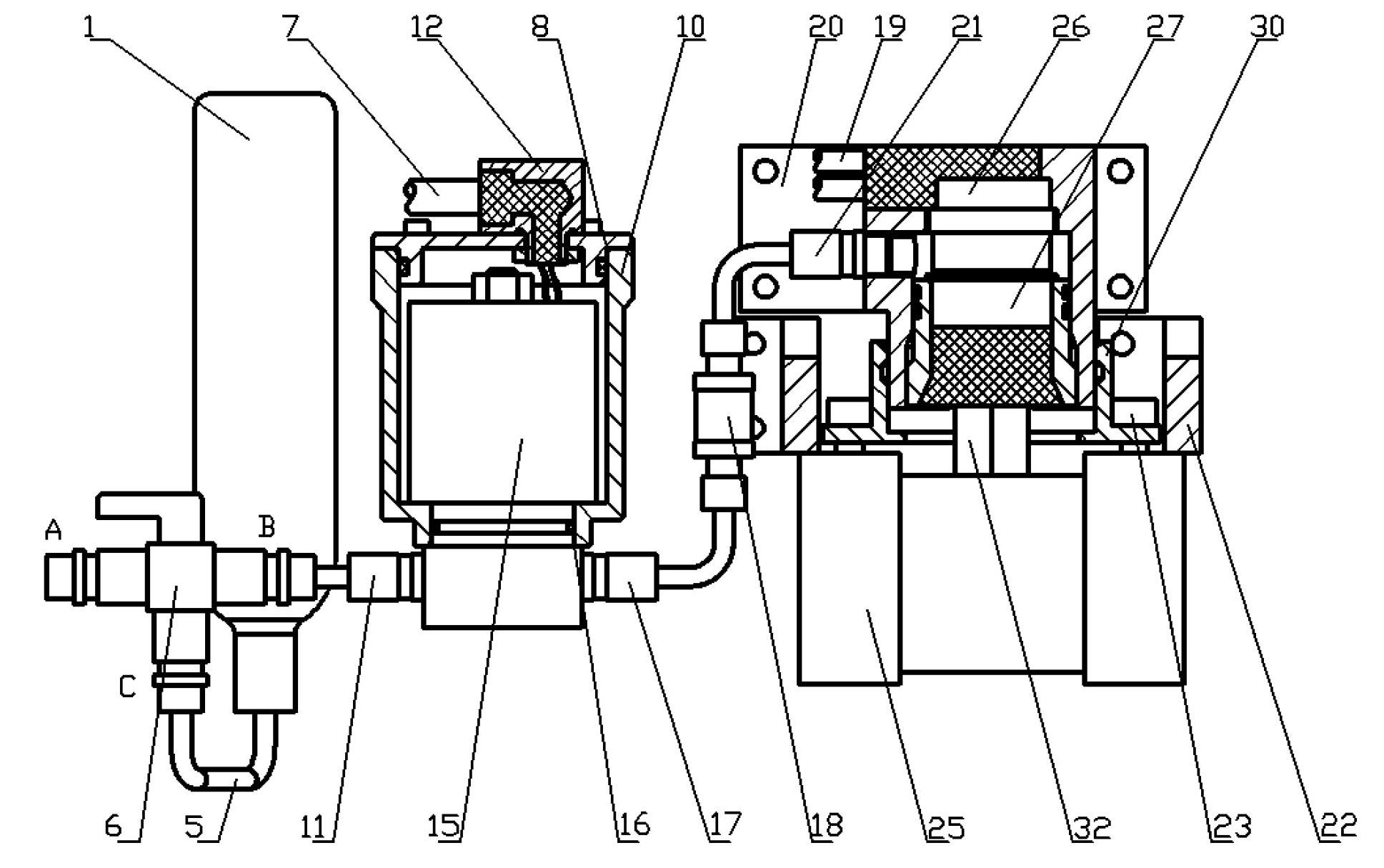

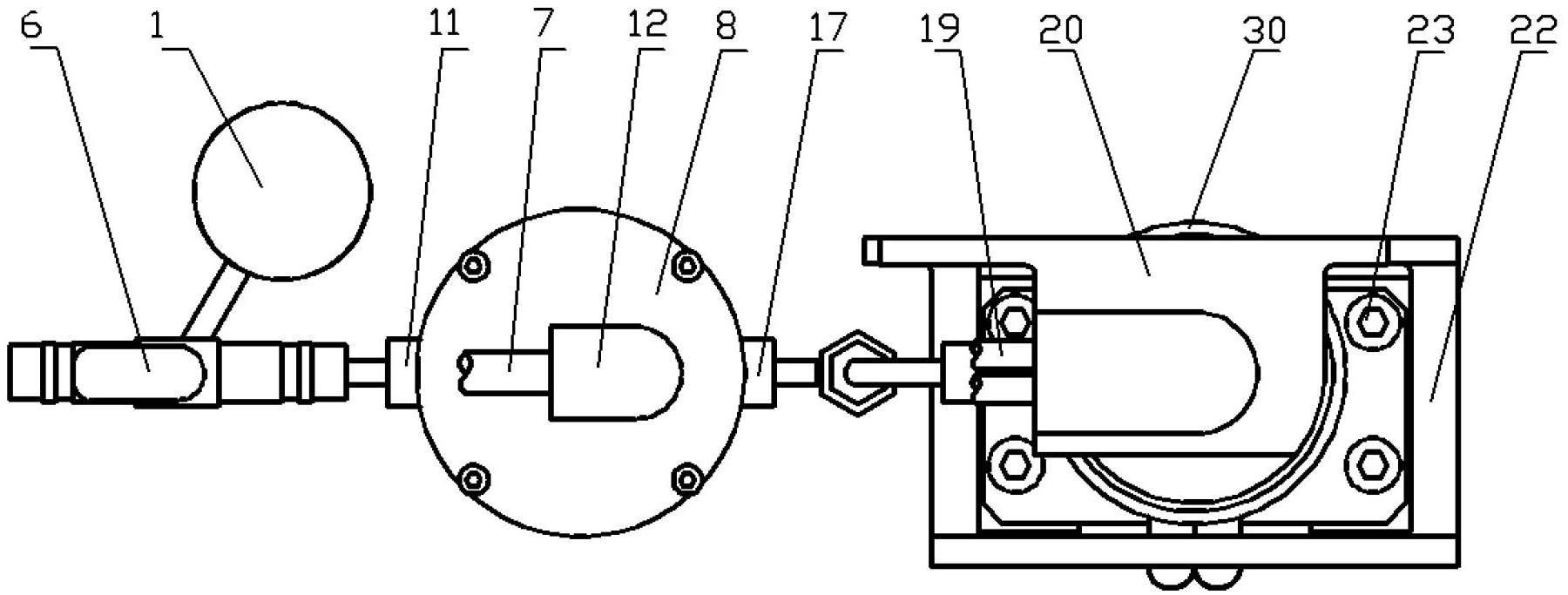

[0034] Such as figure 1 and figure 2 As shown, the present invention is mainly composed of three parts: a high-pressure gas cylinder assembly, a high-pressure solenoid valve assembly, and an emergency release mechanical body assembly. A three-way ball valve 6 is installed between the high-pressure gas cylinder assembly and the high-pressure solenoid valve assembly. A one-way valve 18 is installed between the components of the mechanical body, and each part is connected by a stainless steel high-pressure steel pipe and a high-pressure pipe joint.

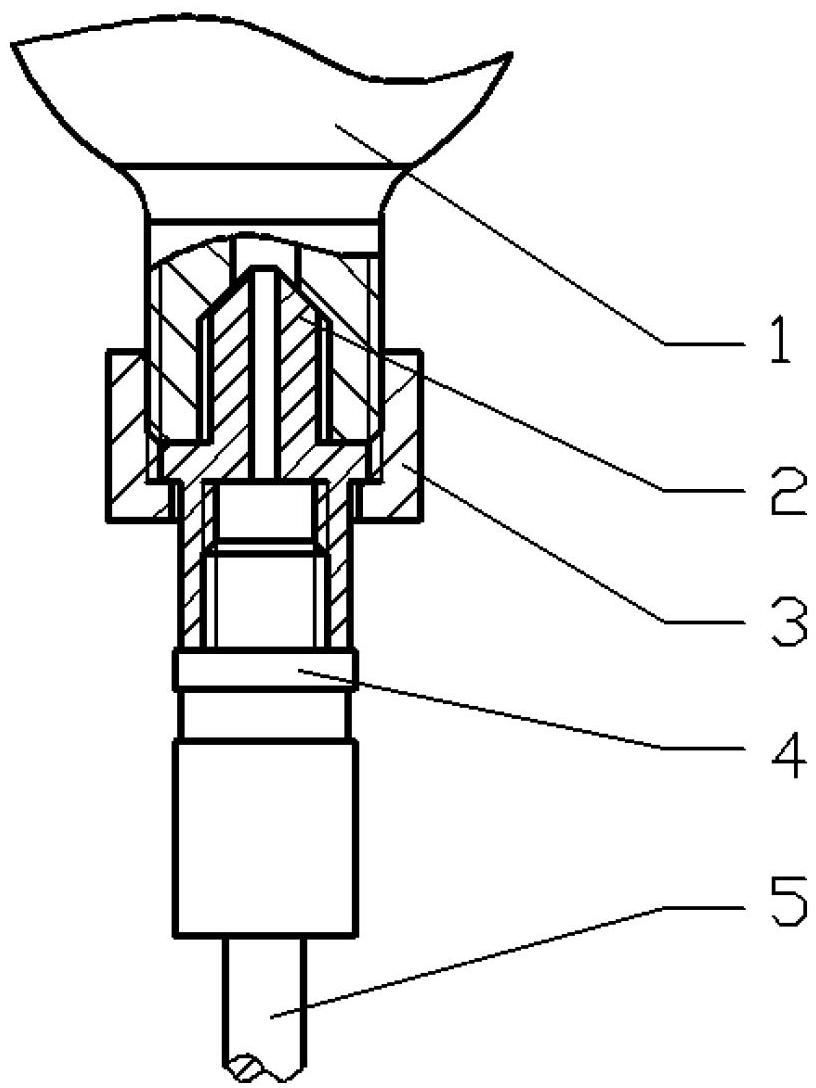

[0035] Such as image 3 As shown, the bottle mouth of the high-pressure gas cylinder 1 is processed with external threads, and the front end of the gas cylinder valve joint 2 is tightly pressed against the inner side of the bottle mouth under the extrusion of the nut 3 to complete the seal. The stainless steel high-pressure pipe joint 4 passes through the sealing pipe thread It is connected with the gas cylinder valve joint 2, and...

specific Embodiment approach 2

[0042] Such as Figure 10 As shown, a set of high-pressure solenoid valve assembly is added on the basis of Embodiment 1. Add threaded holes on the right side of the fixed base 20, connect with the high-pressure pipe joint 34 through the sealing pipe thread, and then connect with the high-pressure solenoid valve 37 valve body through the high-pressure steel pipe 35 and the high-pressure pipe joint 36, and the left end of the high-pressure pipe joint 38 passes through the sealing pipe Thread links to each other with high pressure electromagnetic valve 37 valve bodies, and the right end connects oil bag 39, is full of hydraulic oil in the oil bag 39. When the underwater equipment works normally, the solenoid valve 15 is in a normally closed state, while the solenoid valve 37 is in a normally open state. The hydraulic oil in the oil bag 39 enters the inner cavity of the fixed base 20 through the electromagnetic valve 37 and the steel pipe 35, so that the inner cavity pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com