Life jacket

A life jacket and inner core technology, applied in the field of life jackets, can solve the problems of poor thermal insulation effect, insufficient use of buoyancy, insufficient structure, etc., and achieve the effect of light weight, easy to carry, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

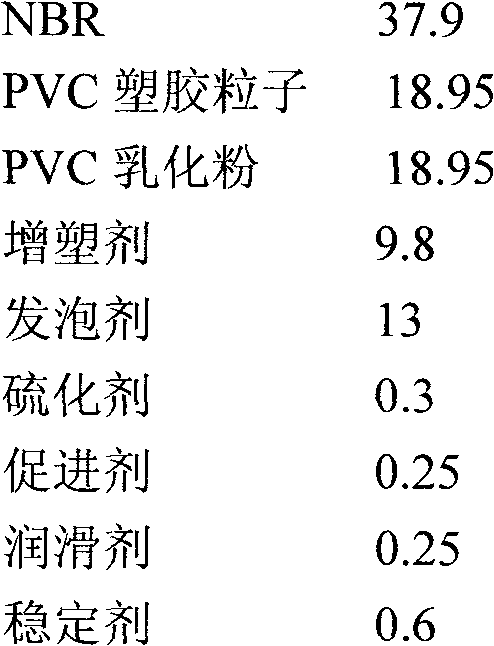

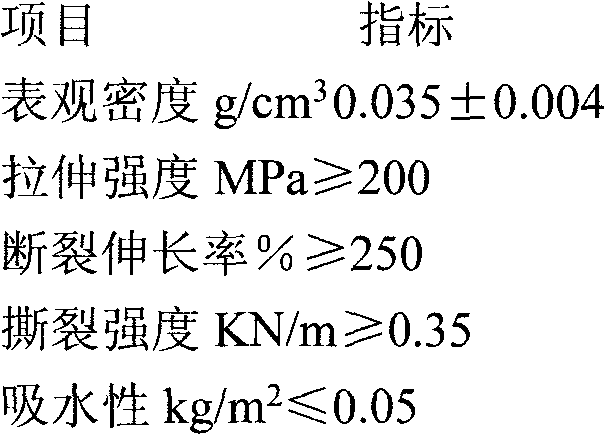

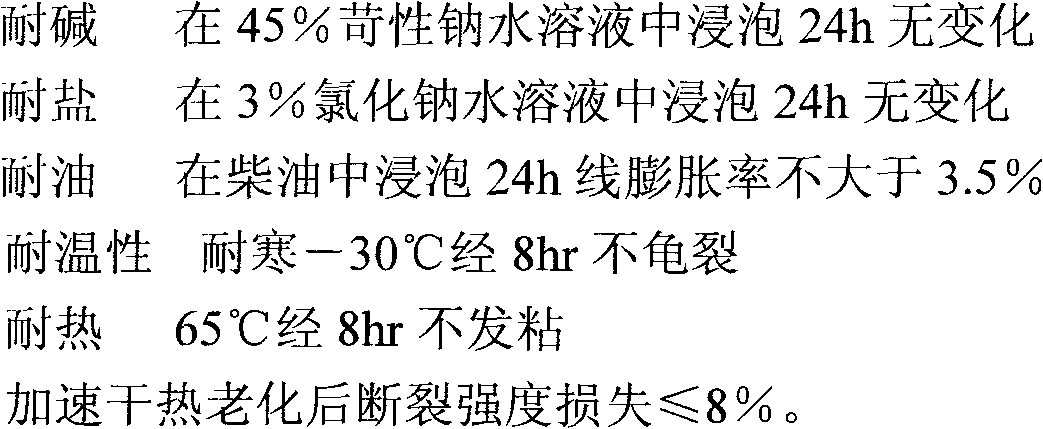

[0016] Embodiment 1, the lifejacket includes an outer jacket and an inner core that acts as a float, the inner core is placed in the interlayer of the outer jacket, and the inner core is made of nitrile rubber and polyvinyl chloride as main raw materials through foaming Foam material, the formula of the inner core is basically composed of: 20% of nitrile rubber, 50% of polyvinyl chloride resin, 0.1% of vulcanizing agent, 0.2% of metal soap lubricant, 9% of plasticizer, and Foaming agent is 20%, and stearate stabilizer is 0.7%, and above-mentioned is mass percent.

[0017] The above-mentioned plasticizer is dioctyl phthalate. The vulcanizing agent is sulfur. The stearate stabilizer is barium stearate, cadmium stearate or zinc stearate. The jacket is made of a face cloth and an inner cloth. The face cloth is made of orange or red polyester cloth that can attract visual attention, and the inner cloth is made of polyester cloth.

[0018] The manufacturing method of the inner co...

Embodiment 2

[0022] Embodiment 2, the lifejacket includes an outer jacket and an inner core that acts as a float, the inner core is placed in the interlayer of the outer jacket, and the inner core is made of nitrile rubber and polyvinyl chloride as main raw materials through foaming Foam material, the formula of the inner core is basically composed of: 10% of nitrile rubber, 60% of polyvinyl chloride resin, 0.2% of vulcanizing agent, 0.3% of metal soap lubricant, 10% of plasticizer, hair Foaming agent is 19%, and stearate stabilizer is 0.5%, and above-mentioned is mass percent.

[0023] The above-mentioned plasticizer is dioctyl phthalate. The vulcanizing agent is sulfur. The stearate stabilizer is barium stearate, cadmium stearate or zinc stearate. The jacket is made of a face cloth and an inner cloth. The face cloth is made of orange or red polyester cloth that can attract visual attention, and the inner cloth is made of polyester cloth.

[0024] The manufacturing method of the inner ...

Embodiment 3

[0028] Embodiment 3, the lifejacket includes an outer jacket and an inner core that acts as a float, the inner core is placed in the interlayer of the outer jacket, and the inner core is made of nitrile rubber and polyvinyl chloride as main raw materials through foaming Foam material, the formula of the inner core is basically composed of: 25% of nitrile rubber, 55% of polyvinyl chloride resin, 0.3% of vulcanizing agent, 0.2% of metal soap lubricant, 7% of plasticizer, and Foaming agent is 12%, and stearate stabilizer is 0.5%, and above-mentioned is mass percent.

[0029] The above-mentioned plasticizer is dioctyl phthalate. The vulcanizing agent is sulfur. The stearate stabilizer is barium stearate, cadmium stearate or zinc stearate. The jacket is made of a face cloth and an inner cloth. The face cloth is made of orange or red polyester cloth that can attract visual attention, and the inner cloth is made of polyester cloth.

[0030] The manufacturing method of the inner co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap