Pressureless sintering method for synthesizing high-purity Ti3SiC2 powder

A high-purity, powder technology, applied in the field of ceramic materials, can solve problems such as complex operation process, low production efficiency, easy oxidation of raw materials and time-consuming, and achieve good economic prospects, good practicability, and good social benefits.

Inactive Publication Date: 2012-09-12

镇江中孚复合材料有限公司

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, most of their synthesis processes involve ball milling and mixing, which have disadvantages such as low production efficiency, complicated operation process, easy oxidation of raw materials and long time consumption, and cannot achieve mass production in industry

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0017] Example 2

Embodiment 2

[0019] Example 3

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

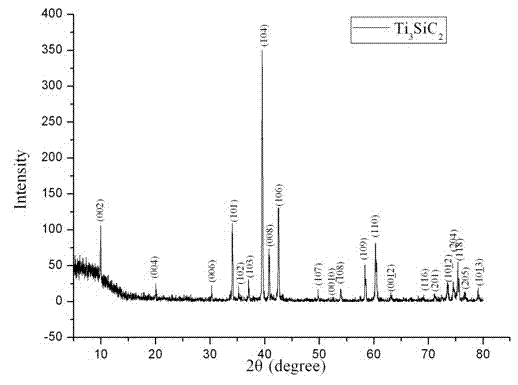

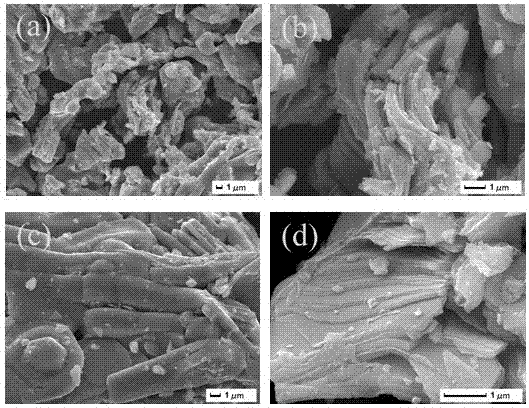

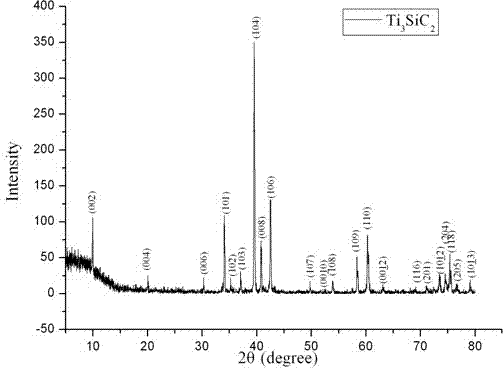

The invention discloses a pressureless sintering method for synthesizing high-purity Ti3SiC2 powder, comprising the following steps of: (1) adding element powders of Ti, Si, C and Al into a container, adding alcohol and heating and stirring the solution for more than 1h at a controlled temperature of 70 DEG C until the alcohol is totally evaporated so that residual powder is obtained, wherein the molar ratio of Ti, Si, C and Al is 3:1:2:0.1; (2) transferring the residual powder to a tubular furnace, sintering the residual powder at 1420 DEG C for 2 to 2.5h in an atmosphere of argon, and cooling the obtained product naturally so that Ti3SiC2 powder is obtained. Element substances of Ti, Si, C and Al are used as raw materials in the invention, and a synthesis of high-purity (96.7 %) Ti3SiC2 powder is achieved by means of optimized mixing and by using a pressureless sintering method at 1420 DEG C under the protection of argon. The method of the invention provides a good practicability, good economic prospects and good social benefits.

Description

technical field [0001] The invention relates to a novel ceramic material, in particular to a pressureless sintering synthesis of high-purity Ti 3 SiC 2 powder method. Background technique [0002] Ti 3 SiC 2 As a new type of ceramic material, which combines many excellent properties of metal and ceramics, it has recently received more and more attention. Ti 3 SiC 2 Belonging to ternary layered compounds, the general formula of this type of compound is M N + 1 AX N (where N=1, 2, 3; M is a transition metal element, A is a IIIA or IVA group element, and X is carbon or nitrogen). They not only have good thermal conductivity, electrical conductivity, relatively soft, good plasticity and superior processability similar to metals, but also have physical and chemical properties similar to ceramic materials, such as high melting point, oxidation resistance, chemical corrosion resistance, and high temperature resistance. and excellent thermal shock resistance. [0003] Ti ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B31/30B82Y40/00C01B32/90

Inventor 李长生杨锋唐华

Owner 镇江中孚复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com