Method for preparing low alkalinity calcium carbonate

A technology of calcium carbonate and low alkalinity, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of high alkalinity and acid resistance, achieve the effect of reducing alkalinity and expanding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

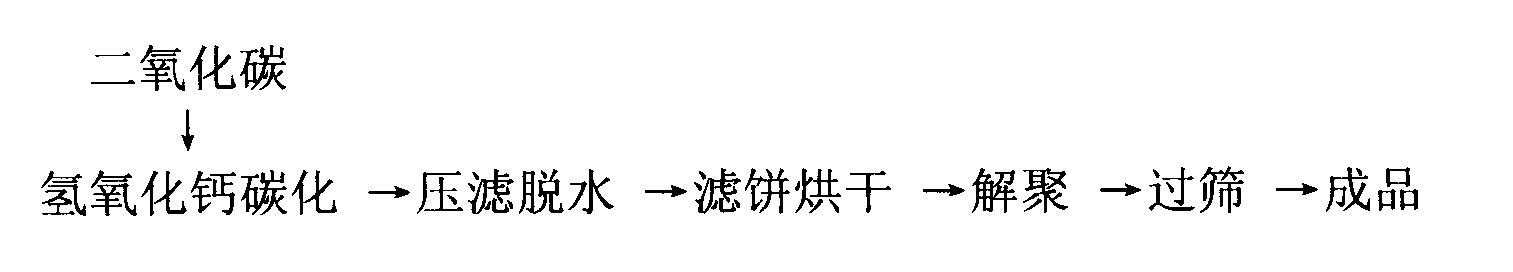

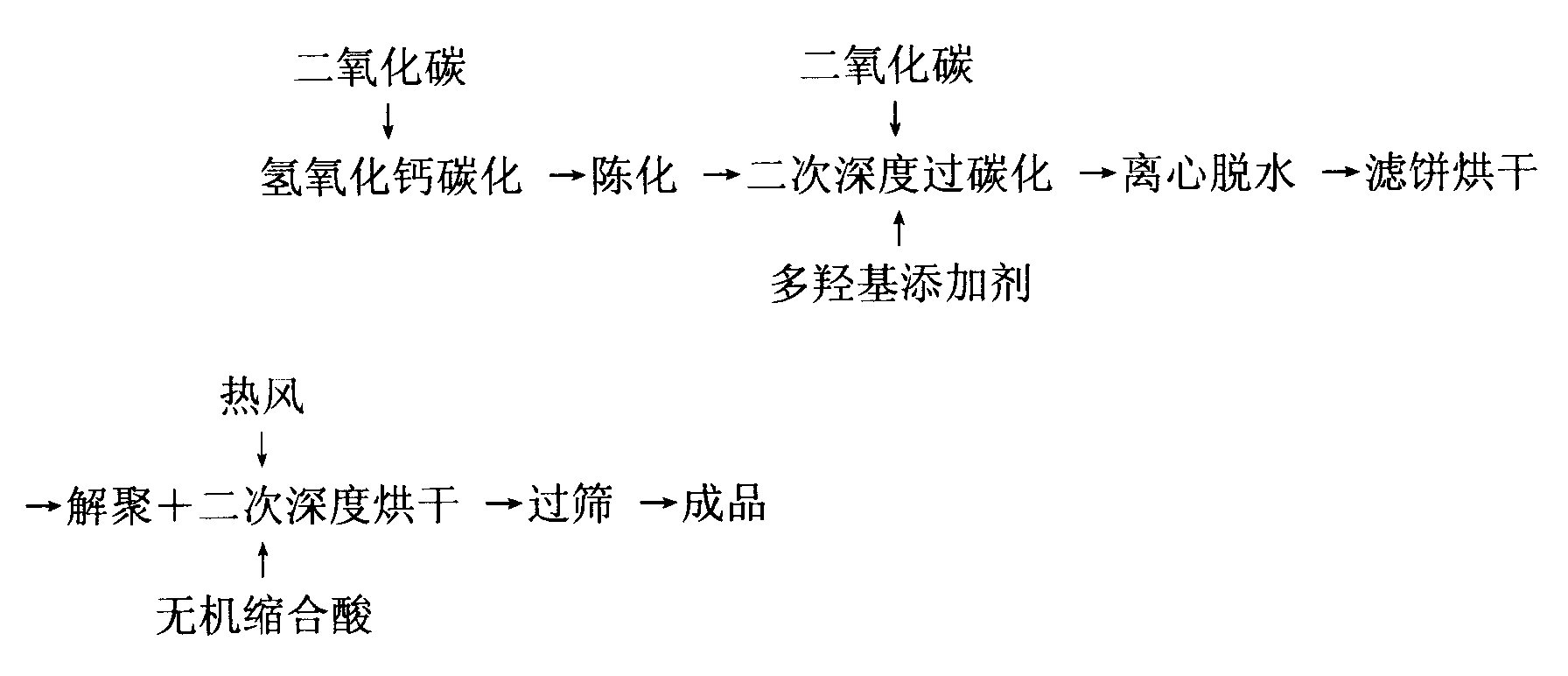

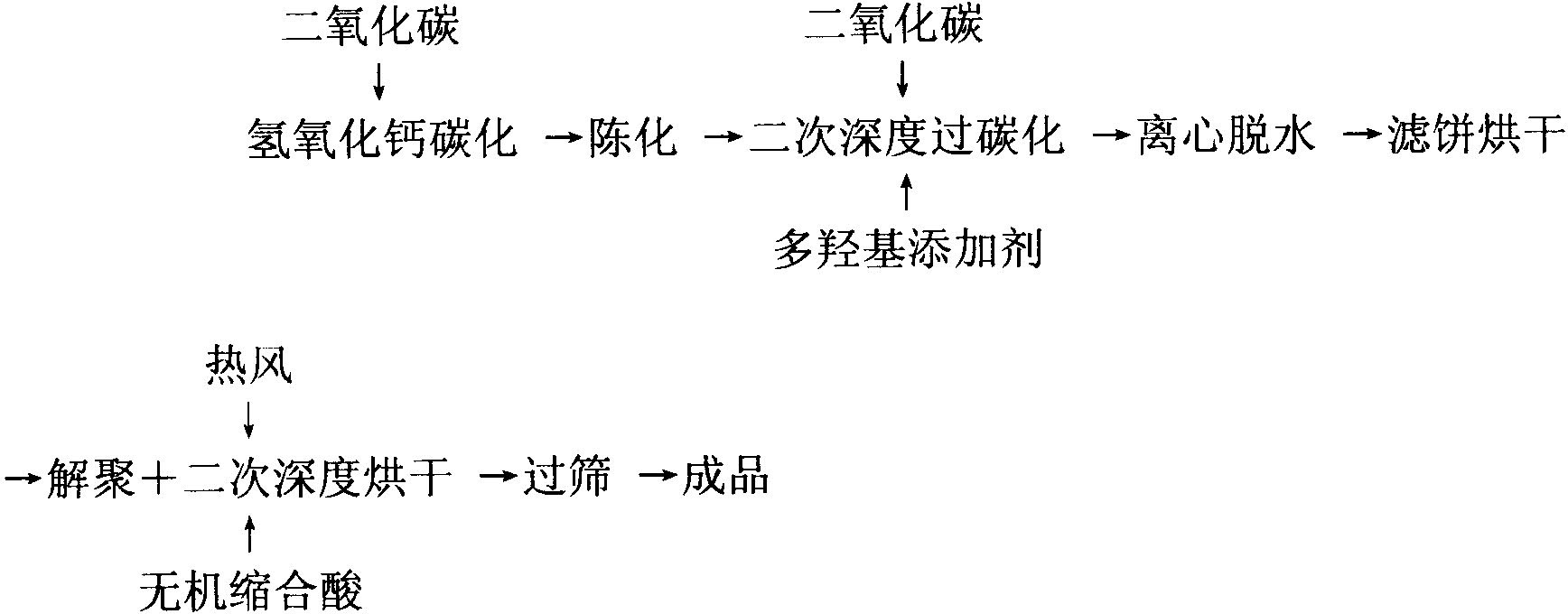

Method used

Image

Examples

Embodiment

[0024] The embodiment of the present invention provides a kind of preparation method that can make calcium carbonate alkalinity be reduced to below ph value 8.0, and the calcium carbonate of certain acid resistance, i.e. the preparation method of low alkalinity calcium carbonate, it is:

[0025] 1. To a certain concentration of Ca(OH) at a certain temperature 2 The suspension is passed through the washed lime kiln flue gas containing carbon dioxide for carbonization, so that Ca(OH) 2 The ph value of the suspension keeps decreasing, and after the ph value reaches 7.0, the carbonization reaches the end point, and calcium carbonate slurry is obtained;

[0026] Two, aging

[0027] After the carbonization finishes, put the prepared calcium carbonate slurry into a storage tank and age for more than 24 hours, so that the pH value of the calcium carbonate slurry is stabilized;

[0028] 3. Secondary deep overcarbonization of calcium carbonate slurry

[0029] Into the aged calcium ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com