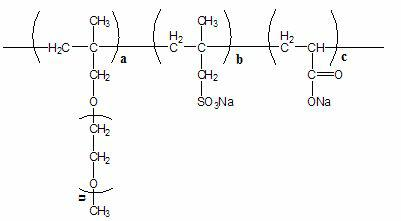

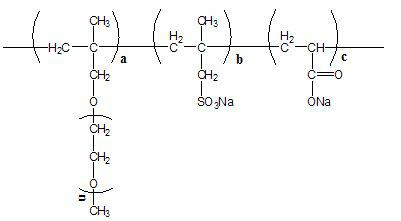

Polycarboxylic water reducer applicable to manufactured sand and preparation method of polycarboxylic water reducer

A technology of polycarboxylic acid and water reducer, which is applied in the field of concrete admixtures, can solve the problems of complicated preparation process and high production cost, and achieve the effects of simple preparation method, improved plastic retention, and improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

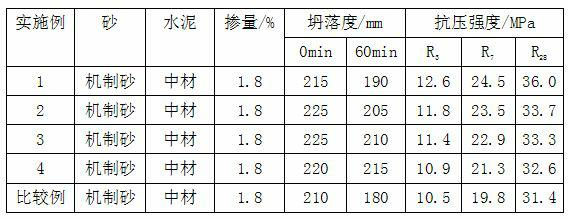

Examples

Embodiment 1

[0021] In the reaction kettle, add 200 kg of 96616 polycarboxylate superplasticizer mother liquor with a solid content of 40%, control the temperature at 25-30°C, add water and 1.5 kg of fatty alcohol sulfonate under stirring conditions, and react for 40 minutes Finally, add 0.25 kg of polyether polyol and react at a constant temperature for 1 to 1.5 hours to obtain a polycarboxylate water reducer suitable for machine-made sand with a solid content of 10%.

Embodiment 2

[0023] In the reaction kettle, add 200 kg of 96616 polycarboxylate superplasticizer mother liquor with a solid content of 40%, control the temperature at 25-30°C, add water and 2.2 kg of fatty alcohol sulfonate under stirring conditions, and react for 40 minutes Finally, add 0.25 kg of polyether polyol and react at a constant temperature for 1 to 1.5 hours to obtain a polycarboxylate water reducer suitable for machine-made sand with a solid content of 10%.

Embodiment 3

[0025] In the reaction kettle, add 200 kg of 96616 polycarboxylate superplasticizer mother liquor with a solid content of 40%, control the temperature at 25-30°C, add water and 3.2 kg of fatty alcohol sulfonate under stirring conditions, and react for 40 minutes Finally, add 0.35 kg of polyether polyol and react at a constant temperature for 1 to 1.5 hours to obtain a polycarboxylate water reducer suitable for machine-made sand with a solid content of 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com