Method and device for detecting fabric skewness

A detection method and fabric technology, applied in textile material inspection, measuring devices, textiles and papermaking, etc., can solve the problems of non-adjustable weft yarn adaptability, small weft yarn adaptability range, difficult production, etc., and achieve simplified structure, wide range, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

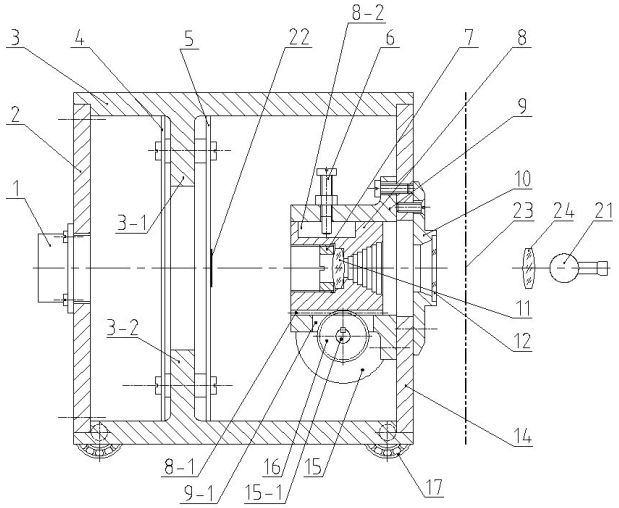

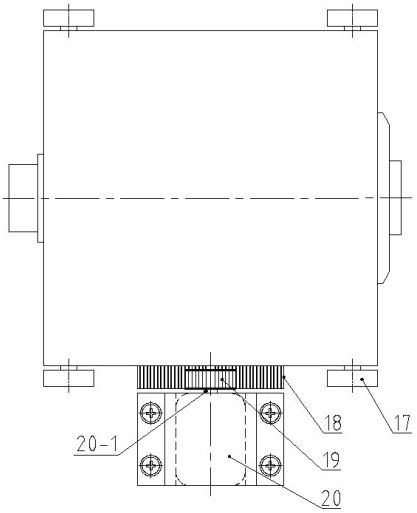

[0031] Example 1: Such as Figure 1 ~ Figure 3 As shown, a photoelectric signal detection head for realizing the detection method of fabric weft skew includes a light source 21, a housing 3, an optical lens 11, a photoelectric sensor 22, an image distance moving device, and an object distance moving device.

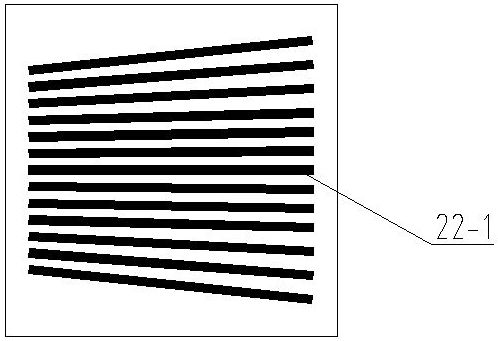

[0032] The photoelectric sensor 22 in this embodiment uses a miniaturized silicon photocell. The size of the miniaturized silicon photocell is 12mm×12mm, and 13 silicon photocell strips that are not in contact with each other are integrated. The horizontal position is the reference cell strip 22-1. The silicon photovoltaic cell bar and the reference cell bar 22-1 form -6°~+6° respectively, and the corresponding arrangement from top to bottom is: +6°, +4.5°, +3°, +1.5°, +1°, +0.5 °, 0°, -0.5°, -1°, -1.5°, -3°, -4.5°, -6°, the minimum resolution accuracy is 0.5°.

[0033] The image distance moving device includes a lens barrel 8, a stepping motor 15, a gear-16 fixed to the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com