Glass reinforced plastic metal composite well and well construction method

A metal composite and construction method technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as construction and inconvenience, and achieve the effect of shortening construction time, short construction period, and reducing construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

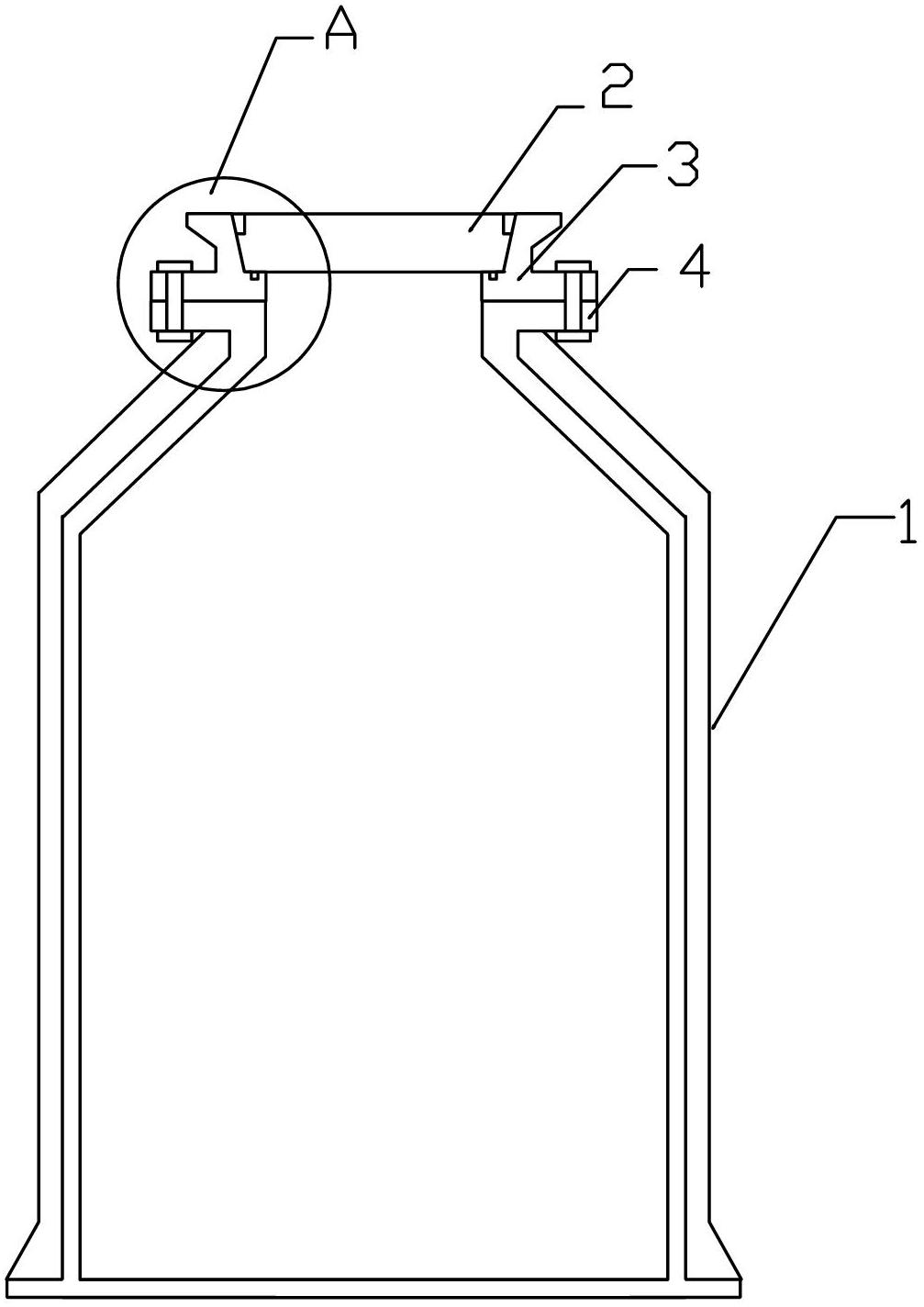

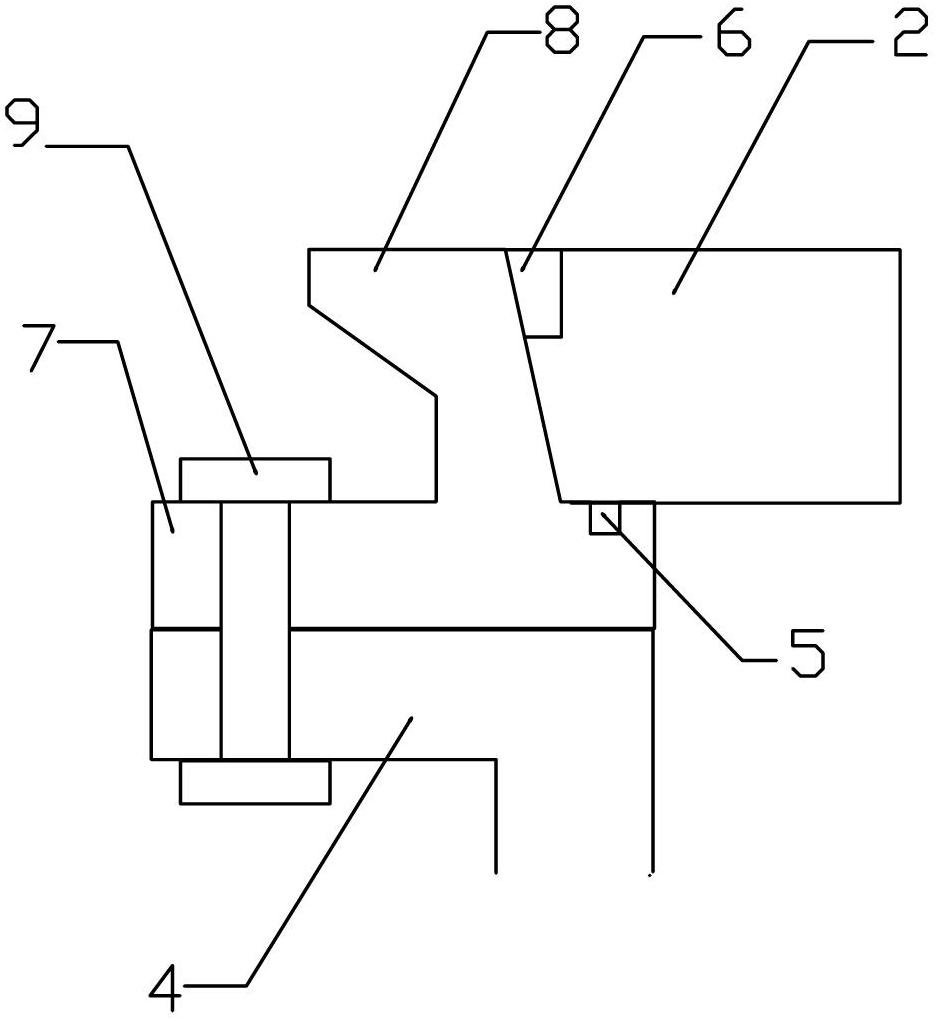

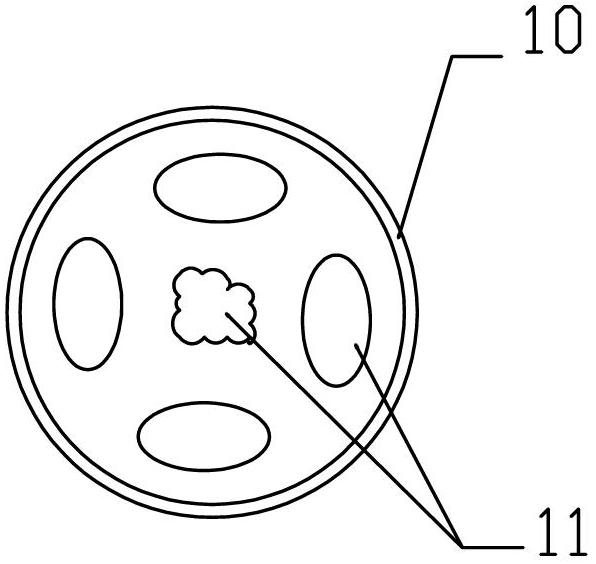

[0049] Such as Figure 1-4 As shown, the FRP metal composite well of the present invention includes a well body 1 and a well cover 2, and the top of the well body 1 is provided with a wellhead; the FRP metal composite well also includes a well collar 3; Adapted bottom ring 7 and the joint part 8 arranged above the bottom ring 7 and adapted to the well cover; the bottom ring 7 is detachably connected to the wellhead; the well cover 2 is covered on the On the bottom ring 7 inside the joint part 8, the side wall is attached to the joint part 8; wherein, the well body 1 is a glass fiber reinforced plastic well body, and the well collar 3 is a metal well collar or an alloy well collar; The manhole cover 2 is a metal manhole cover or an alloy manhole cover.

[0050]The outer edge of the wellhead is provided with a sub-flange 4 integrally formed with the wellhead; Flange; the well ring 3 and the FRP well body 1 are connected by flange bolts.

[0051] The connection side of the joi...

Embodiment 2

[0061] Embodiment two: the well construction method of the present invention comprises the following steps:

[0062] Step 1: Open the well slot from the surface downward;

[0063] Step 2: Put the above-mentioned FRP composite well into the well groove;

[0064] Step 3: Fill the gap between the well groove and the FRP composite well with adhesive, concrete or soil to level the ground surface.

[0065] The height of the well groove is not less than the height of the FRP well body. In the specific implementation process, if the depth of the well groove is not enough, the FRP well body is exposed on the surface and exposed to ultraviolet rays, which is easy to age and shorten the service life.

[0066] The well construction of the present invention adopts the fiberglass composite well described in the present invention, which is quick and convenient, and is not restricted by the geographical environment. At the same time, the height of the well groove is set to be not less than...

Embodiment 3

[0067] Example 3: FRP-metal composite wells applied to airports or other places with explosion-proof requirements

[0068] Such as Figure 1-4 As shown, the FRP metal composite well of the present invention includes a well body 1 and a well cover 2, and the top of the well body 1 is provided with a wellhead; the FRP metal composite well also includes a well collar 3; Adapted bottom ring 7 and the joint part 8 arranged above the bottom ring 7 and adapted to the well cover; the bottom ring 7 is detachably connected to the wellhead; the well cover 2 is covered on the On the bottom ring 7 inside the joint part 8, the side wall is attached to the joint part 8; wherein, the well body 1 is a glass fiber reinforced plastic well body, and the well collar 3 is a metal well collar or an alloy well collar; The manhole cover 2 is a metal manhole cover or an alloy manhole cover.

[0069] The outer edge of the wellhead is provided with a sub-flange 4 integrally formed with the wellhead; F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com