Hydraulic integral-type tensioning ring of water separation tube

A riser, integral technology, used in drilling pipes, casings, drilling equipment, etc., can solve the problems of high operating risks for operators, complicated connection and disassembly operations, etc., to improve safety and reliability, wide application range, friction Low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the drawings and specific embodiments.

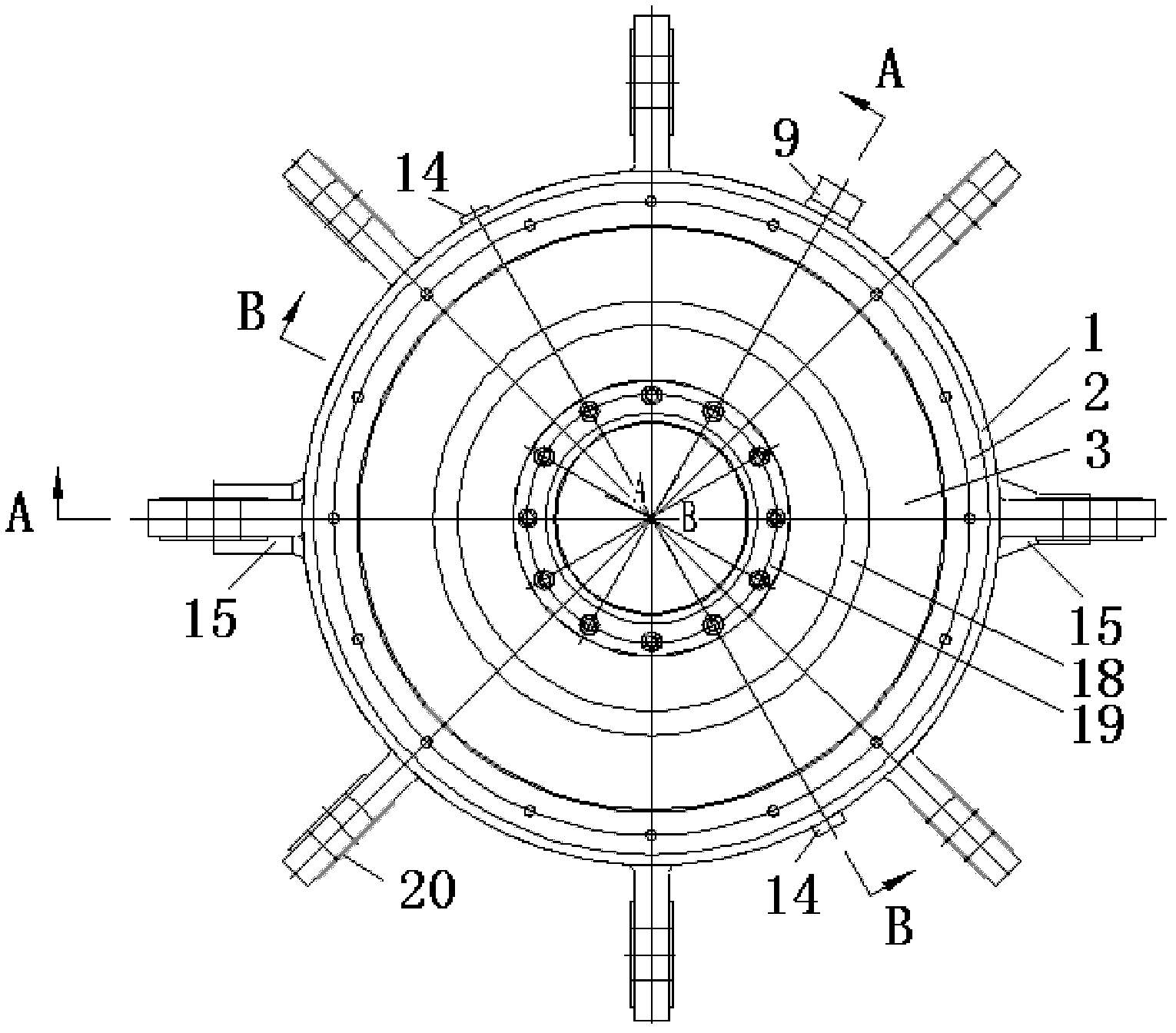

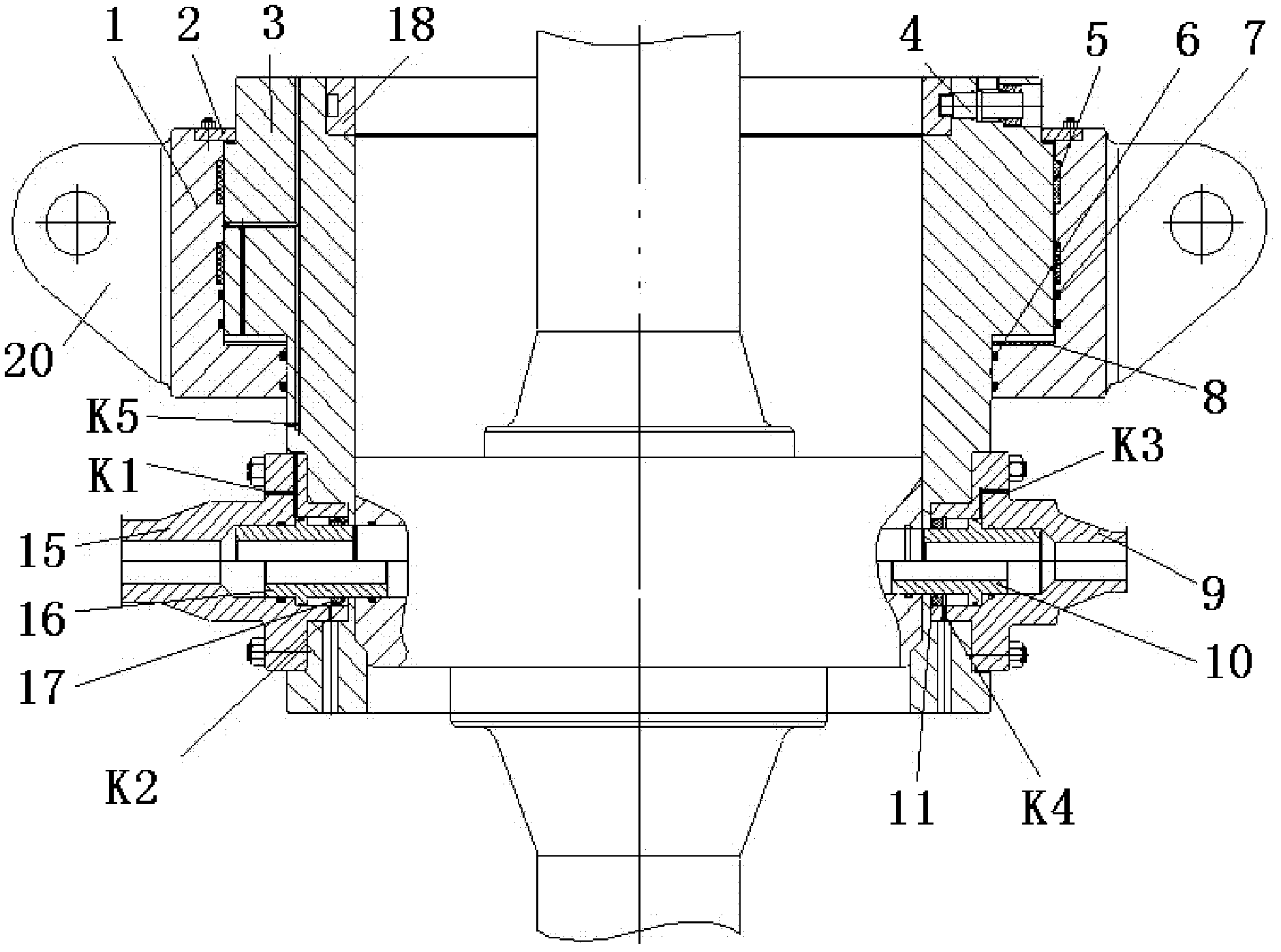

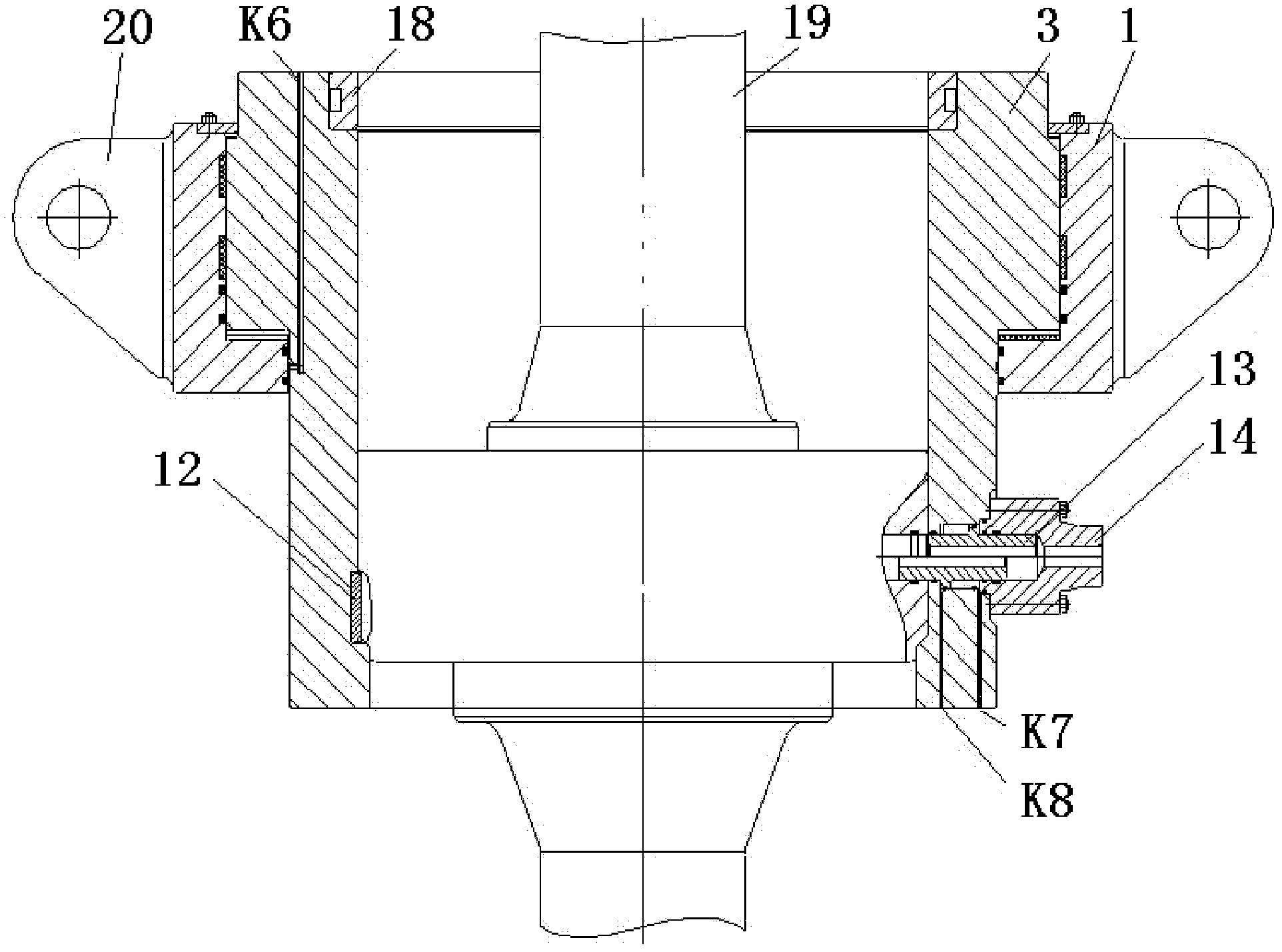

[0021] Reference figure 1 , figure 2 , image 3 , The structure of the hydraulic integral riser tension ring of the present invention is to include the pressure ring 1, the gland 2, the bearing body 3, the connecting lock pin assembly 4, the wear ring 5, the rotary seal I 6, the rotary seal II7, Pressure-bearing gasket 8, mud booster pipeline discharge terminal body 9, mud booster pipeline sealing mandrel 10, mud booster pipeline sealing piston 11, guide key 12, hydraulic pipeline sealing mandrel 13, hydraulic pipeline discharge terminal body 14, The choke / kill pipeline discharge terminal body 15, the choke / kill pipeline sealing mandrel 16, the choke / kill pipeline sealing piston 17, the drilling diverter shell 18, and the riser expansion device 19. among them, figure 1 It is a schematic top view of the riser tension ring, which clarifies the relative positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com