Energy-saving running control system and method for tunnel construction ventilation system

A technology for tunnel construction and operation control, which is applied in mine/tunnel ventilation, pump control, earthwork drilling and mining, etc. It can solve the problems of underutilized energy saving potential and energy waste in tunnel construction, and achieve fast data transmission speed, The effect of high communication reliability and reduction of energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

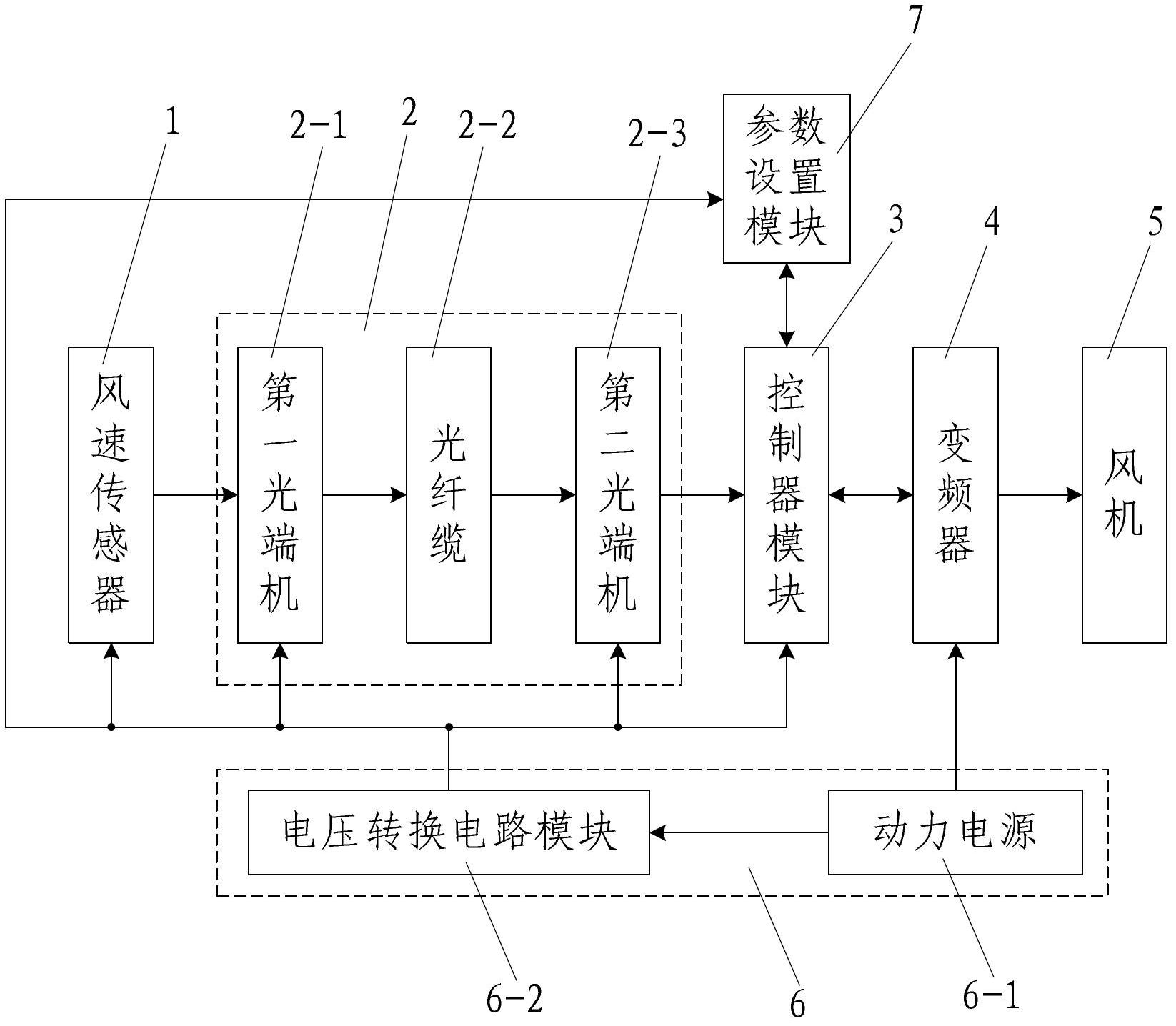

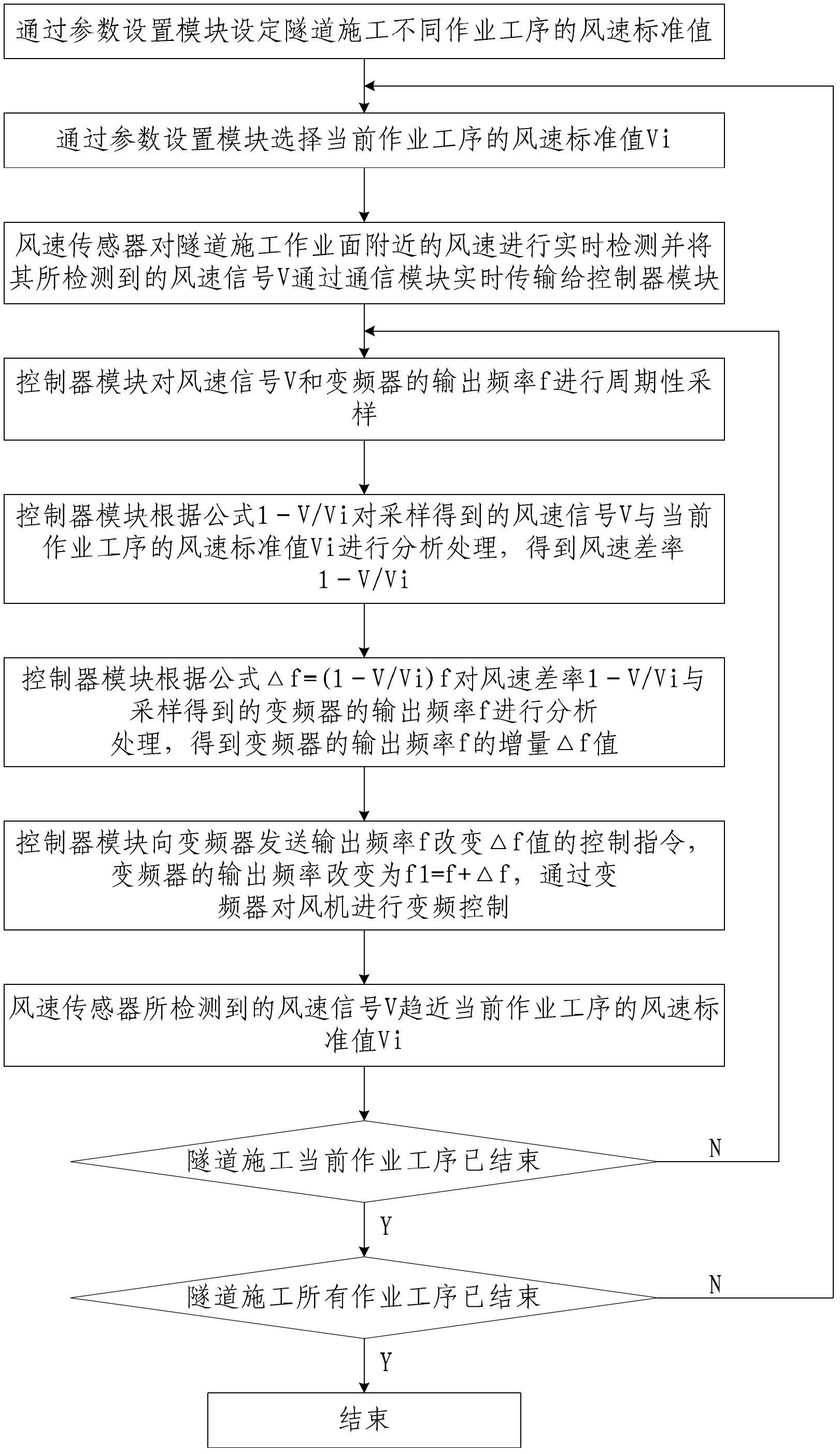

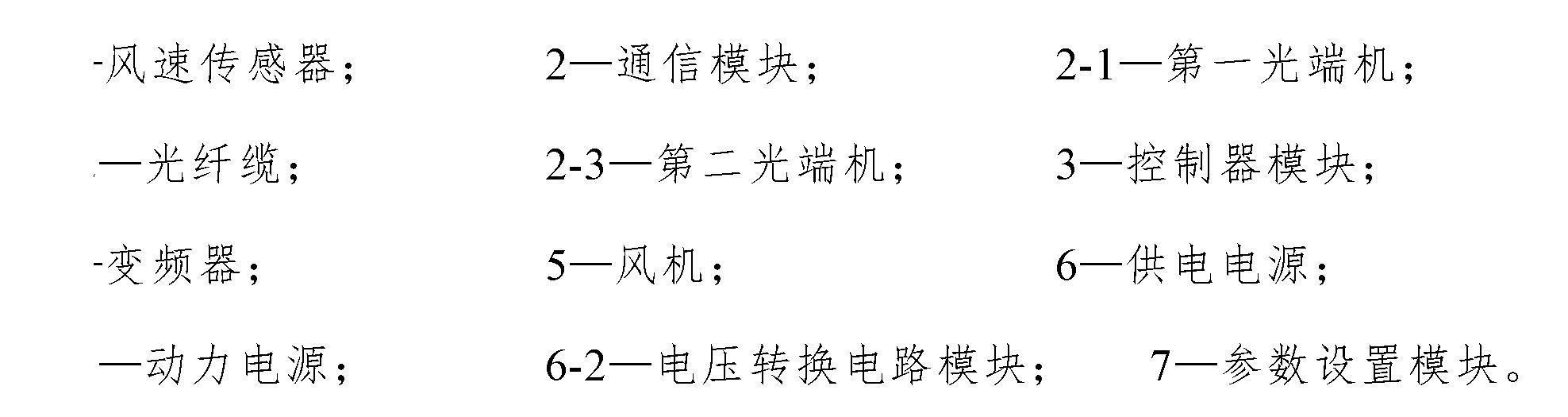

[0049] Such as figure 1 As shown, the tunnel construction ventilation system energy-saving operation control system according to the present invention includes a power supply 6 and a controller module 3, and a parameter setting module 7 connected with the controller module 3 and used to set the wind speed standard value and used for According to the control command output by the controller module 3, the frequency converter 4 is used for frequency conversion and speed regulation of the speed of the fan 5, the fan 5 is connected to the output end of the frequency converter 4, and the input end of the controller module 3 is connected to a A communication module 2, the input terminal of the communication module 2 is connected with a wind speed sensor 1 arranged near the tunnel construction surface and used for real-time detection of wind speed, and the power supply 6 includes a power supply 6 for powering the frequency converter 4 -1, and a voltage conversion circuit module 6-2 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com