Jointed rock mass test piece and jointed rock mass and aqueous rock coupling test method

A technology of water-rock coupling and fractured rock mass, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem of inability to quantitatively describe the mechanical properties of rock mass, etc. Experiment with simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

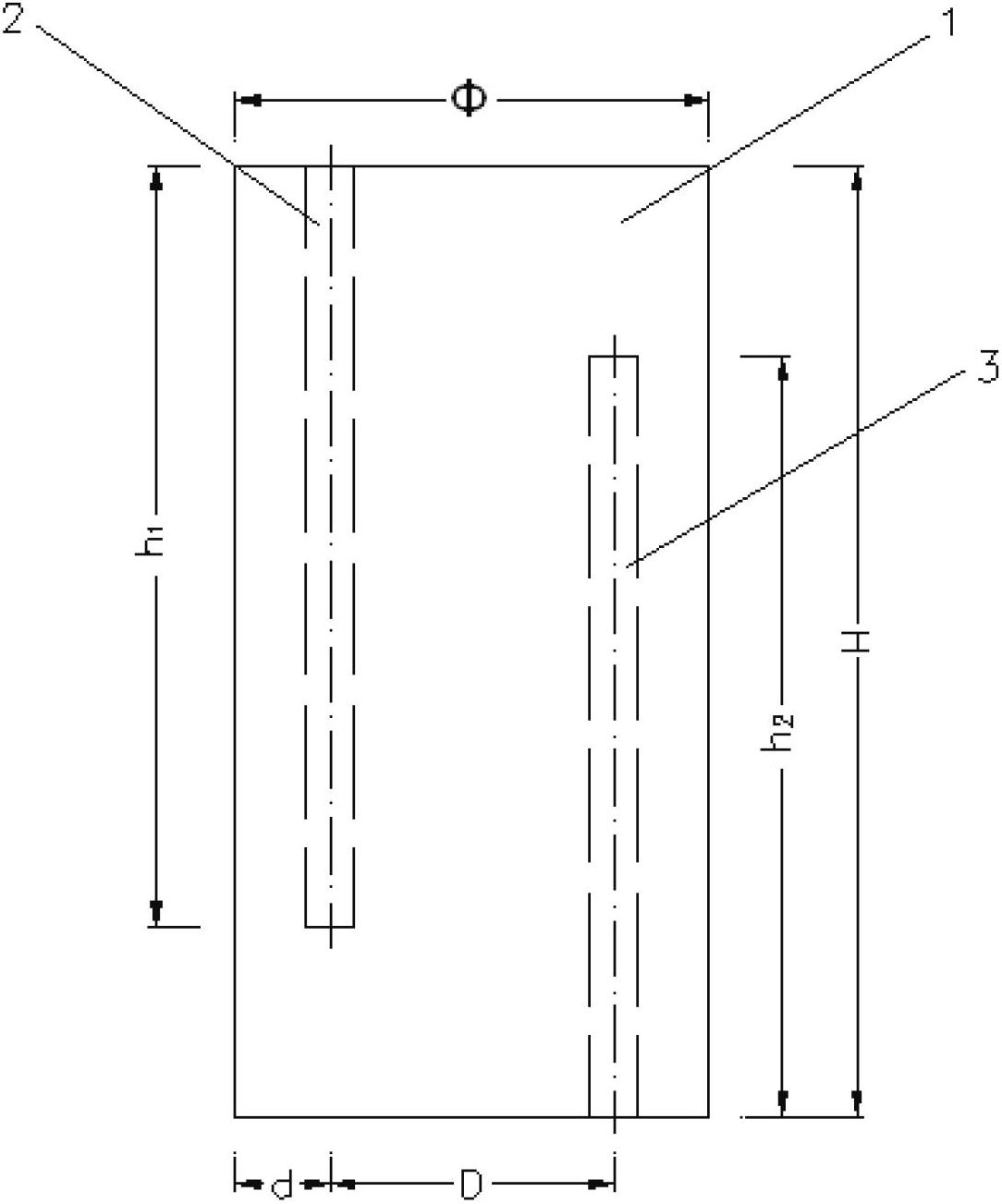

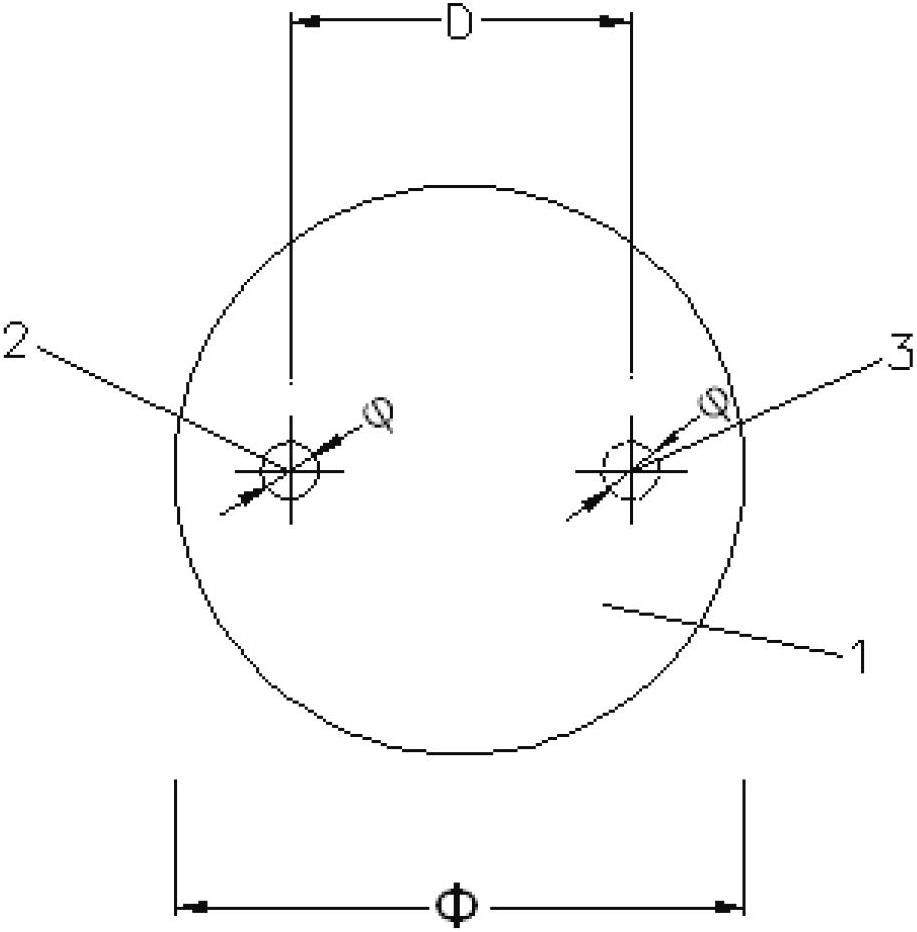

[0035] In this embodiment, the shape and structure of the rock sample are as follows figure 1 , figure 2 As shown, the body 1 is cylindrical, the height of the cylindrical body is H=100mm, and the diameter Φ=50mm. A blind water guide hole is processed on both ends of the cylindrical body, which are respectively named as the first blind water guide hole 2 and the second guide water guide hole. Blind water hole 3, the centerlines of the first blind water guide hole 2 and the second blind water guide hole 3 are located on the plane passing through the centerline of the rock block test piece, and are distributed axially symmetrically with respect to the center line of the rock block test piece. The distance between the centerlines is 30mm, the aperture φ of the two holes is 6mm, the depth of the two holes is 80mm, and the distance between the centerline of the two holes and the outer edge of the cylindrical body 1 is 10mm.

[0036] The rock block test pieces in this embodiment a...

Embodiment 2

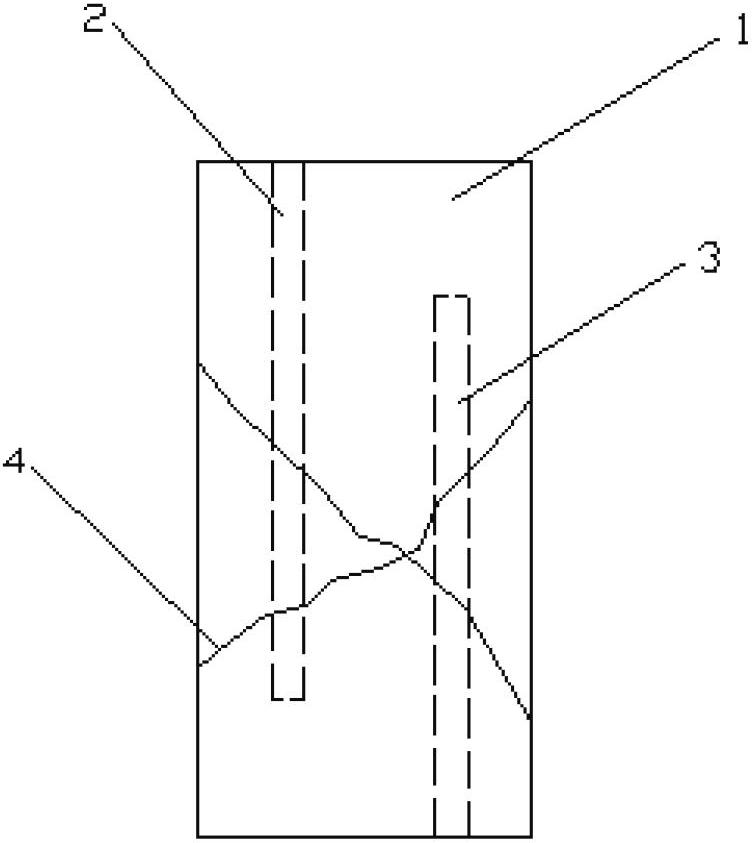

[0038] The 6 rock test pieces described in Example 1 are installed on the rock mechanics test equipment, carry out the triaxial compression whole process test to each rock block test piece under 60MPa confining pressure, its fracturing and make the fracture in the test piece The seepage channel connected with the water-guiding blind hole is formed, that is, the fractured rock mass specimen is formed, and its shape is shown in image 3 .

Embodiment 3

[0040] In this embodiment, the rock mass of the dam foundation of a large hydropower station is tested. The dam foundation of a large-scale hydropower station is composed of rock mass with a fracture surface, which is called the dam foundation rock mass. A large number of investigation and research work have obtained the main mechanical properties and parameters of the dam foundation rock mass. The parameters include the rock mass when it was formed. The minimum principal stress (equivalent to confining pressure) σ in the rock mass stress field 3 ′, the minimum principal stress σ in the stress field of the rock mass at the time of the test 3 , friction coefficient f in rock, cohesion c, and deformation modulus E. The main results obtained from survey research are: σ 3 'not less than 60MPa, σ 3 Generally not more than 30MPa, f is 0.43, c is 4.2MPa, and E is 2~3GPa. After the hydropower dam is completed, it will store water to generate electricity, and the water storage heigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com