Variable-tilt-angle stepless loading type biaxial rotary oscillation ball-block friction-abrasion test machine

A friction and wear test, stepless loading technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problem of single swing range of the testing machine, and achieve the effect of compact structure, low manufacturing cost, simple and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

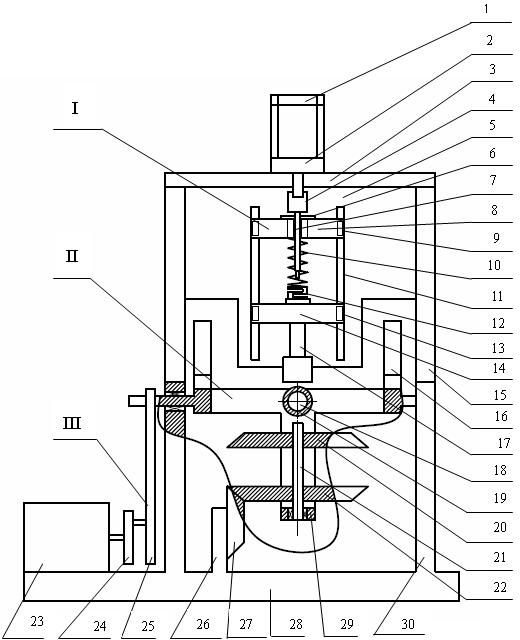

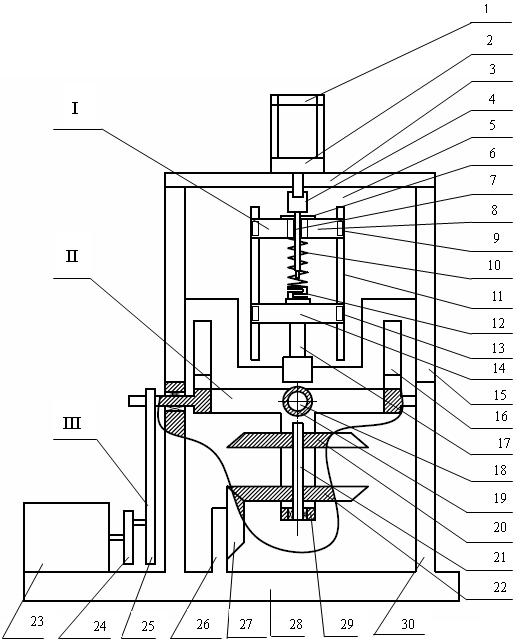

[0018] Embodiment 1: Referring to the accompanying drawings, this ball-block friction and wear testing machine with variable swing angle stepless loading type biaxial rotation and swing includes a bottom frame (28), a frame, a loading part (I), a biaxial Rotating swinging part (II) and driving part (III), characterized by:

[0019] 1) The loading part (I) is a stepless loading mechanism, installed on the upper part of the frame, driven by a servo motor (1) and a ball screw (7), and transmits the loading force to a buffer spring (10) The sample block holder (17) realizes the stepless loading of the sample block to the dual sample ball;

[0020] 2) The driving part (III) drives a crank (24) with a sliding groove and a rocker (25) to move through an asynchronous motor (23), and the rocker (25) is connected with the biaxial rotary swing mechanism ( II) one end short shaft of a belt shaft swing frame (29) is connected;

[0021] 3) The biaxially rotating swinging part (II) is fixe...

Embodiment 2

[0022] Embodiment 2: This embodiment is basically the same as Embodiment 1. The special feature is that the loading part (1) is installed on the loading support plate (5) and fixed on the left and right support plates (15) through bolt connection. The loading part The power of (I) is provided by the servo motor (1), and the connecting block (8) installed on the guide rail slider is driven by the lower coupling (4) and the ball screw (7), and the loading force is loaded by the buffer spring (10 ) to the sample block holder (17) below; the servo motor (1) in the loading part (I) is fixed on the motor support plate (3) through the mounting block (2), and through the coupling (4) Connected with the ball screw (7), the ball screw nut (6) is connected with the guide rail slider (9) through the connecting block (8), so the ball screw nut (6) can move along the linear guide rail (11) performs linear motion, and transmits the loading force to the sample block holder (17) through the bu...

Embodiment 3

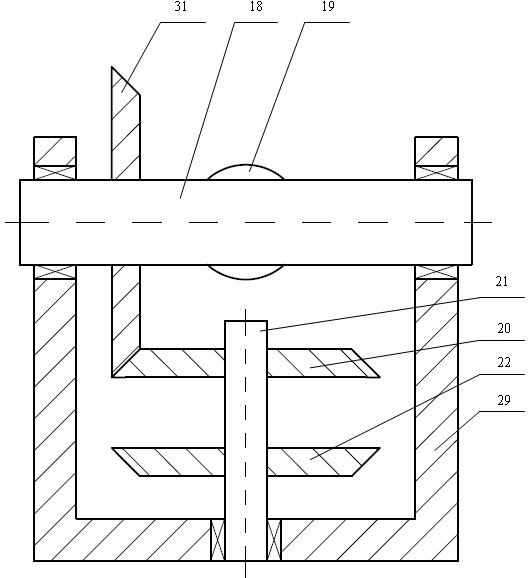

[0023] Embodiment 3: This embodiment is basically the same as Embodiment 1, and the special feature is that the two-stage bevel gear transmission mechanism in the biaxially rotating oscillating part (II) is: the gear shaft (21) is simply supported by the bearing on the In the center of the bottom of the belt shaft swing frame (29), its center line is aligned with the center of the dual sample ball (19), and the upper bevel gear (20) and the lower bevel gear (22) are coaxially fixed on the gear shaft (21) ), fixedly install the fixed bevel gear (27) on the machine base (28) through the gear fixing plate (26) to mesh with the lower bevel gear (22), and fix a The vertical bevel gear (31) meshes with the upper bevel gear (20). Balance weights (16) with sliding grooves are installed on both sides of the swinging frame in the biaxially rotating swinging part (II), and the balancing weights (16) with sliding grooves are fixed to the swinging frame with shafts (29) by screws , so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com