External rotor motor

An external rotor motor and external rotor technology, applied in electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve the problems of green environmental protection, energy saving and emission reduction, affecting the process of motor production, and increasing the cost of magnetic tile materials. , to achieve the effect of sturdy structure, easy regenerative braking ability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

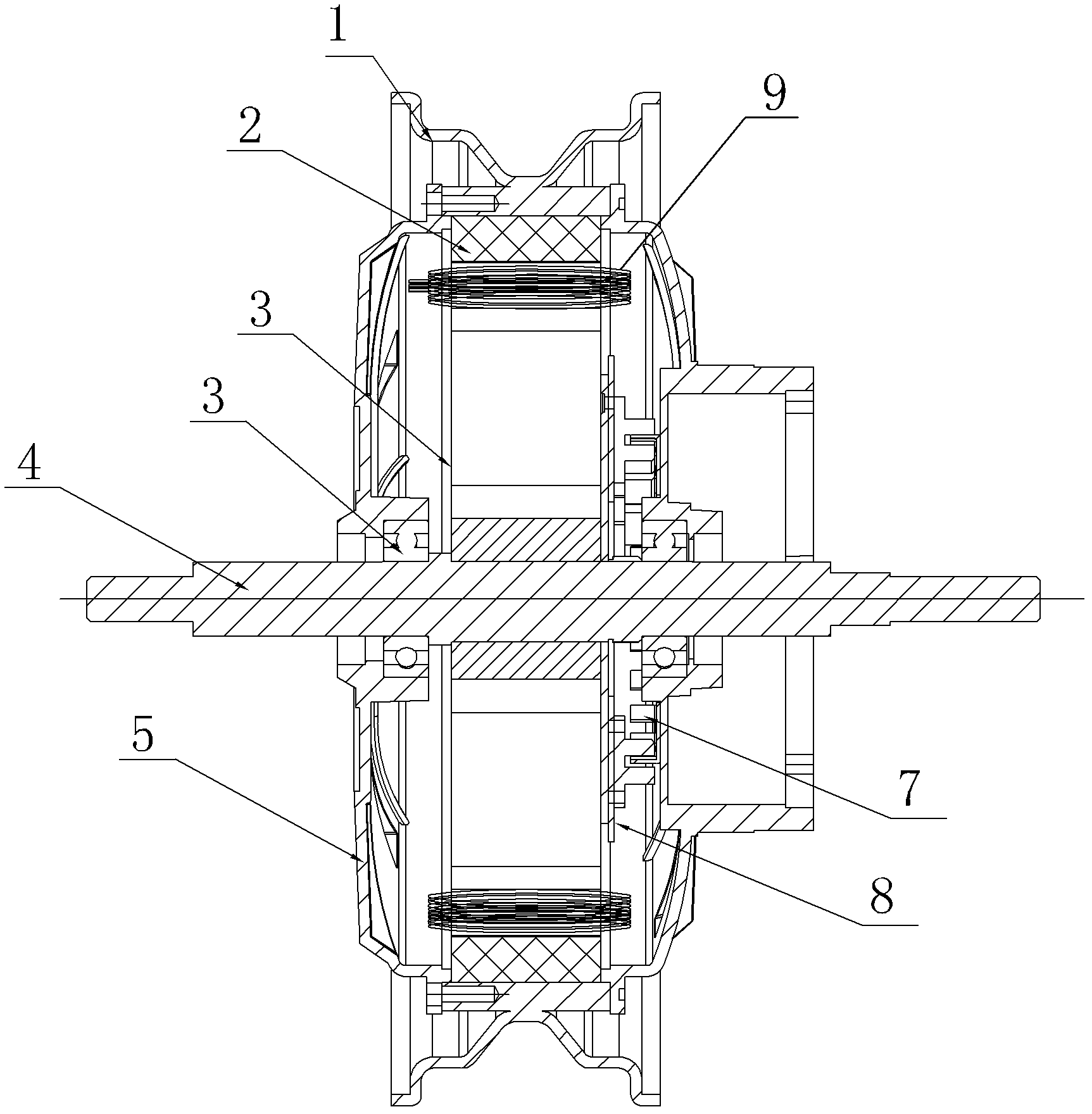

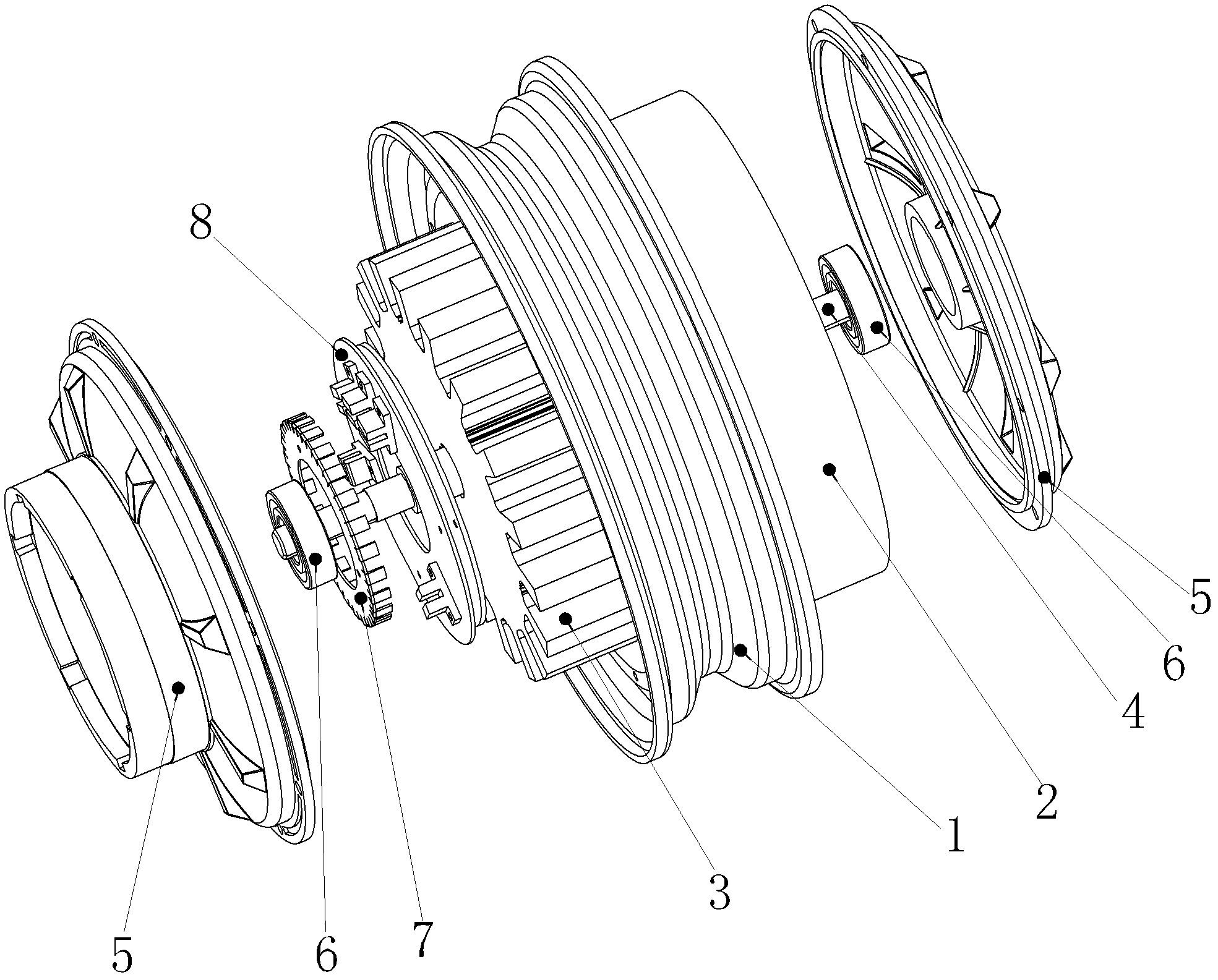

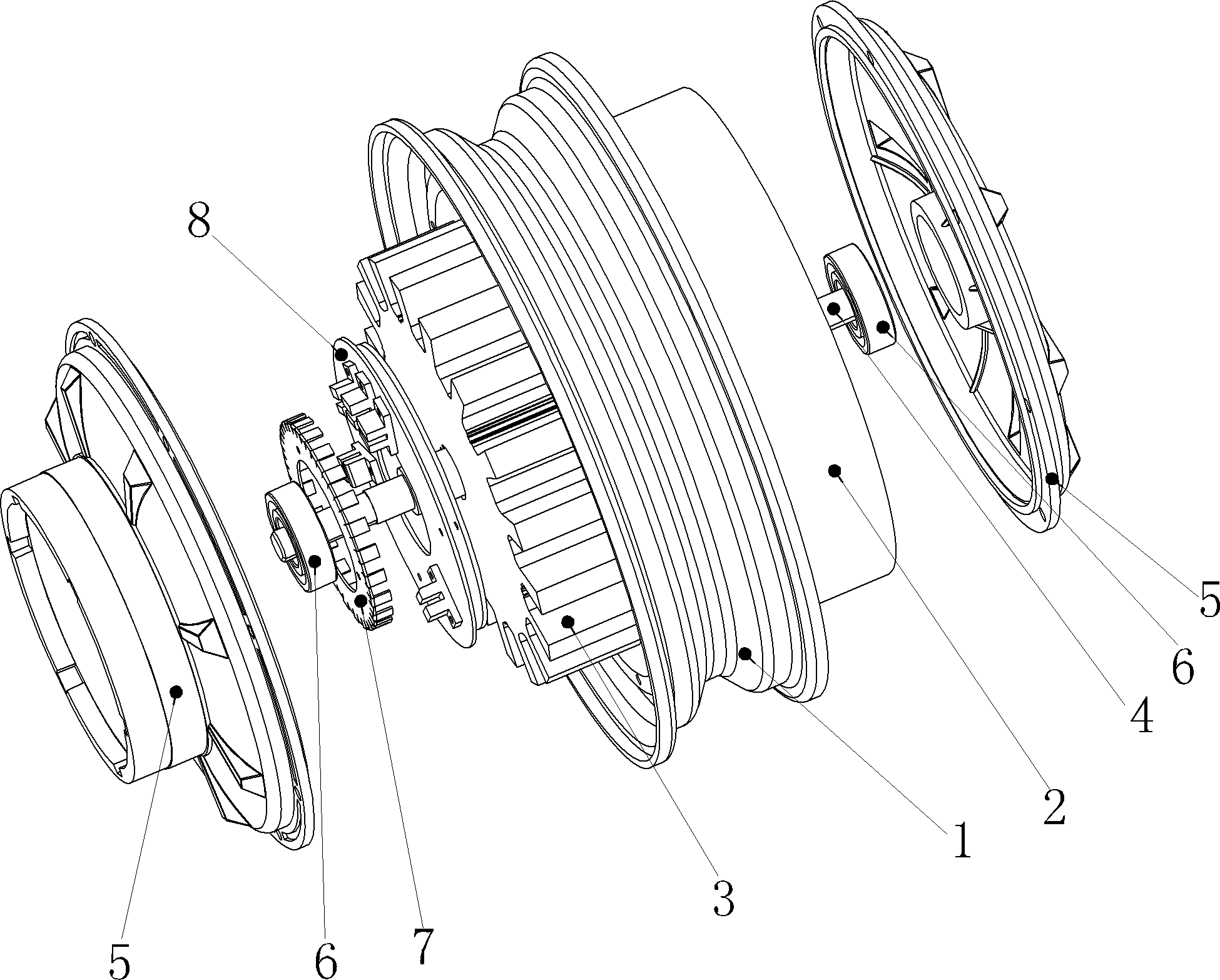

[0021] Embodiment: a kind of outer rotor motor of the present invention, as figure 1 , figure 2 As shown, it includes a hub 1, a motor shaft 4, an outer rotor 2 without windings or magnetic tiles, and an inner stator 3 with windings 9. Both the outer rotor 2 and the inner stator 3 have protruding tooth poles. End caps 5 are installed on both sides, and both ends of the motor shaft 4 are mounted on the end caps 5 through bearings 6. The inner stator 3 and the motor shaft 4 are fixedly sleeved together, the outer rotor 2 is tightly connected with the hub 1, and the inner stator 3 A photoelectric panel element 8 is installed on one side of the photoelectric panel element 8, and a grating 7 for commutation is installed on the end cover on the same side as the photoelectric panel element 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com