Continuous evaporator

An evaporator, horizontal technology, applied in the field of once-through evaporation, can solve problems such as technical complexity, achieve the effects of improving flow distribution, reducing mechanical stress, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

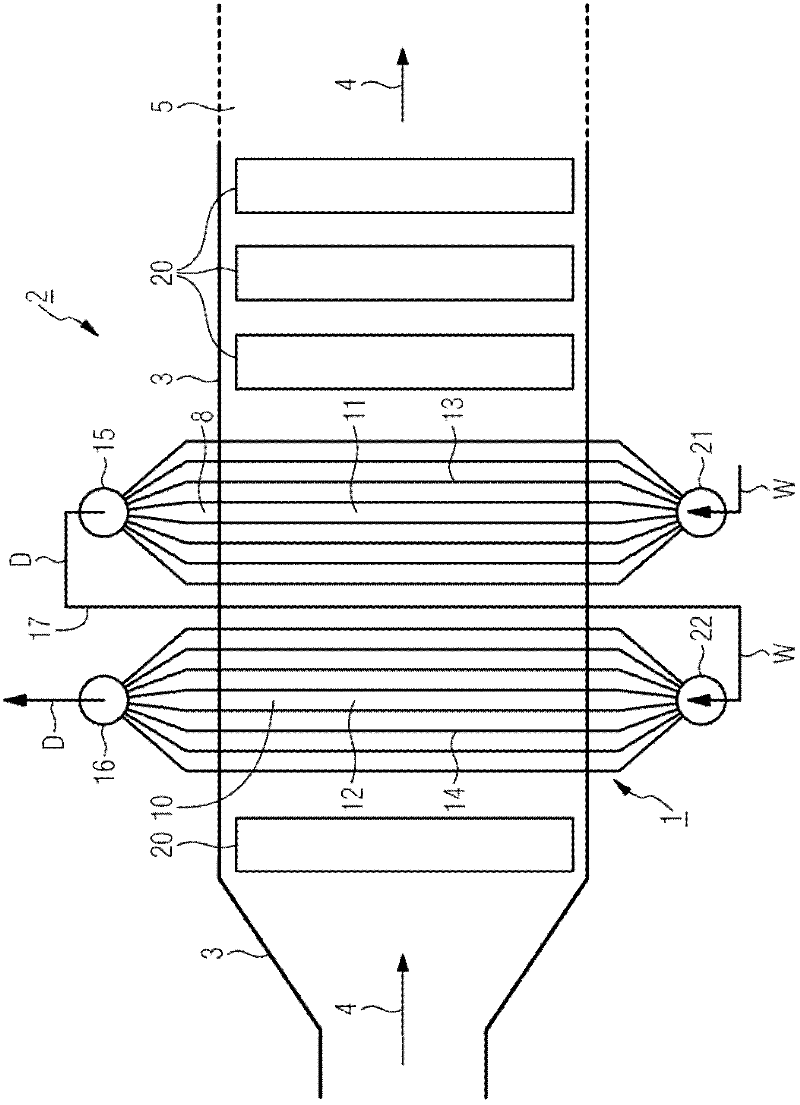

[0024] The same reference numerals are used for the same parts in all figures.

[0025] according to figure 1 The once-through evaporator 1 for the waste heat boiler 2 is connected downstream of the gas turbine, not shown in detail, with respect to the exhaust gas. The waste heat boiler 2 has a surrounding wall 3, which forms a gas channel 5 for the exhaust gas from the gas turbine, which can flow in a generally horizontal gas direction indicated by arrow 4. In the gas passage 5, some evaporator heating surfaces 8, 10 designed according to the principle of direct flow are arranged. in press figure 1 In the embodiment shown two evaporator heating surfaces 8, 10 are shown, but a larger number of evaporator heating surfaces can also be configured.

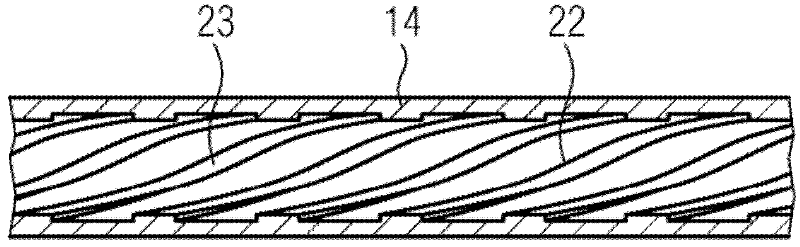

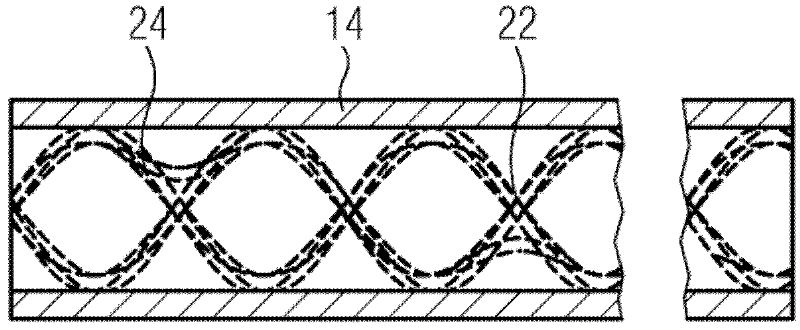

[0026] according to figure 1 The heating surfaces 8 and 10 of the evaporators respectively comprise some tube rows 11 or 12 arranged one behind the other along the gas direction in the form of tube bundles. Each tube row 11 or 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com