Preparation method for carmine radish and prepared product

A technology of rouge radish and radish sauce, which is applied in the field of food processing, can solve the problems of poor utilization of resources, few types of products, and loss of nutrition, etc., and achieve the goal of improving utilization rate and added value, enriching the market, and low sugar content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

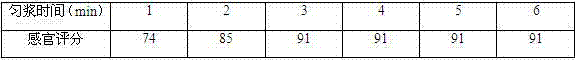

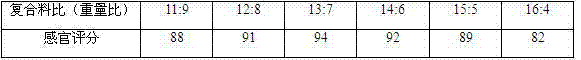

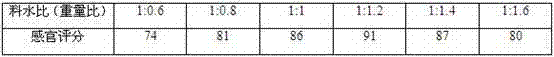

[0018] Embodiment 1, the ratio of raw and auxiliary materials of rouge radish sauce and the optimization of preparation condition parameters

[0019] Raw materials: rouge radish, kudzu root, white sugar, salt, citric acid, xanthan gum.

[0020] Preparation method: a. Preparation of rouge radish pulp: select fresh rouge radishes that are nine-ripe, with dense and crisp tissue, no bran core, no germination, and no pests and diseases, wash with water, and cut into about 1cm 3 For large or small blocks, add water equivalent to 0.5 times the weight of rouge radish, heat to boil, remove foam, let it cool, and beat it into a homogenate with a homogenizer to obtain rouge radish pulp. The purpose of adding water and precooking before beating is mainly to soften the tissue of rouge radish and indirectly exhaust it to remove the peculiar smell of rouge radish;

[0021] b. Preparation of kudzu root pulp: select fresh kudzu root that is nine-ripe, mildew-free, and moth-eaten, wash with...

Embodiment 2

[0085] Embodiment 2, the preparation of rouge radish sauce (with rouge radish and kudzu root as main raw materials)

[0086] Raw materials: rouge radish, kudzu root, white sugar, citric acid, salt, xanthan gum.

[0087] Preparation method: a. Preparation of rouge radish pulp: select fresh rouge radishes that are nine-ripe, with dense and crisp tissue, no bran core, no germination, and no pests and diseases, wash with water, and cut into about 1cm 3 For large or small lumps, add water equivalent to 0.5 times the weight of rouge radish, heat to boil, remove foam, let cool, beat with a homogenizer at a speed of 8000r / min for 3 minutes, and obtain rouge radish slurry;

[0088] b. Preparation of kudzu root pulp: select fresh kudzu root that is nine-ripe, mildew-free, and moth-eaten, wash with water, and cut into about 1cm 3 block size, add water equivalent to 1.2 times the weight of kudzu root, beat with a homogenizer at a speed of 9000r / min for 3 minutes, filter with gauze to...

Embodiment 3

[0091] Embodiment 3, the preparation of rouge radish sauce (with rouge radish and yam as main raw materials)

[0092] Raw materials: rouge radish, yam, white sugar, citric acid, salt, xanthan gum.

[0093] Preparation method: a. Preparation of rouge radish pulp: select fresh rouge radishes that are nine-ripe, with dense and crisp tissue, no bran core, no germination, and no pests and diseases, wash with water, and cut into about 1cm 3 For large or small lumps, add water equivalent to 0.5 times the weight of rouge radish, heat to boil, remove foam, let cool, beat with a homogenizer at a speed of 8000r / min for 3 minutes, and obtain rouge radish slurry;

[0094] b. Preparation of yam pulp: select fresh yams that are nine-ripe, mildew-free, and moth-eaten, wash with water, and cut into about 1cm 3 For large or small lumps, add water equivalent to 1.2 times the weight of yam, beat with a homogenizer at a speed of 9000r / min for 3 minutes, filter with gauze to remove coarse fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com