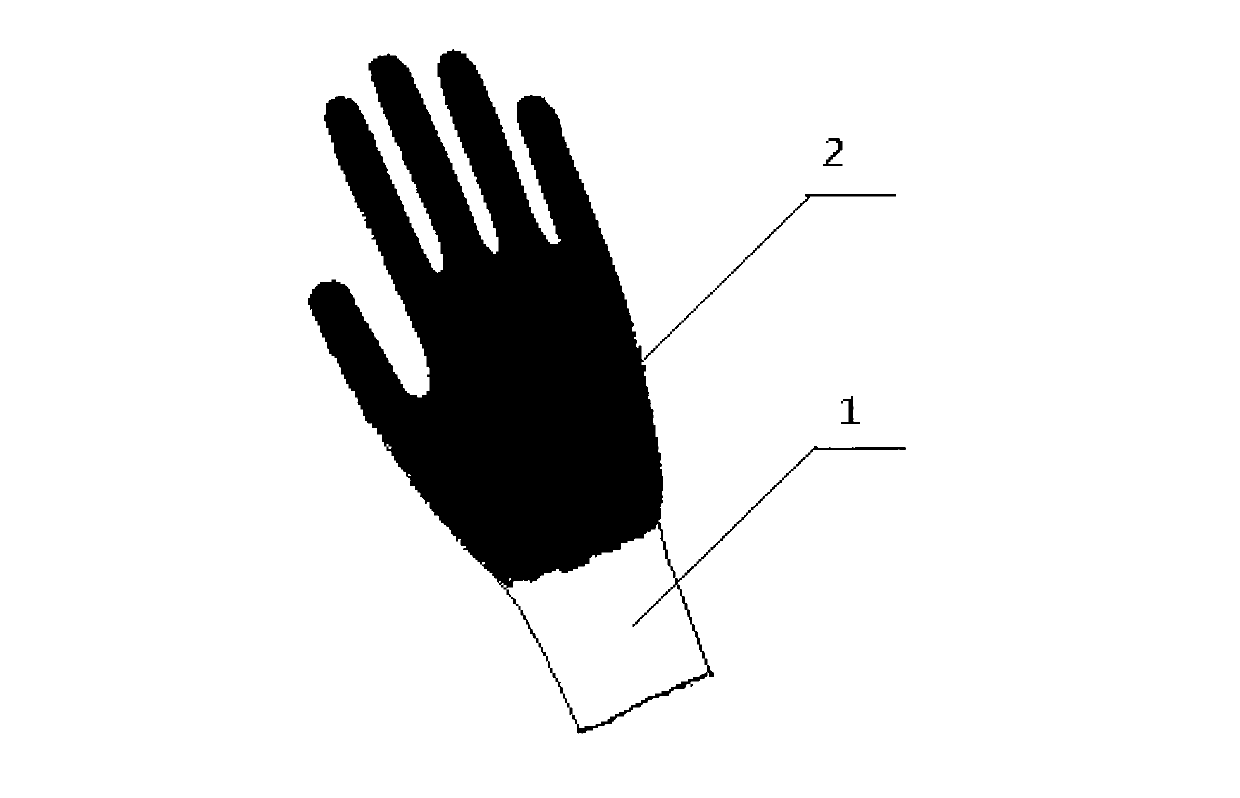

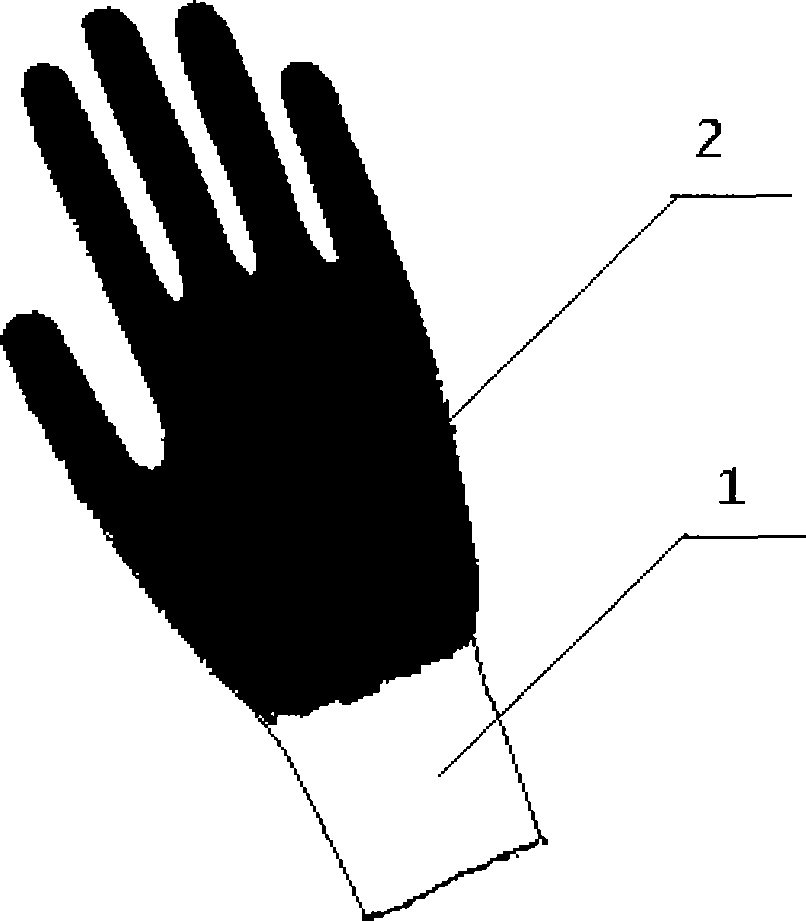

Waterborne polyurethane coating glove and production process thereof

A water-based polyurethane and production process technology, applied in gloves, clothing, clothing, etc., can solve the problems of complex process, high curing temperature, and defoaming agent, and achieve broad market prospects, simple production process, and soft products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of production technology of waterborne polyurethane coated gloves, concrete steps comprise;

[0030] 1. Preheating: Put the fabric glove core on the hand mold, enter the drying tunnel, set the temperature of the drying tunnel to 60 degrees Celsius, and preheat for 10 minutes.

[0031] 2. Soak the coagulant. The coagulant is a volatile organic acid; mix 94 parts of water and 6 parts of formic acid evenly and put it in the coagulant tank of the assembly line; until no liquid drips out.

[0032] 3. Baking: the hand mold enters the oven, the oven temperature is set at 60 degrees Celsius, and baked for 10 minutes.

[0033] 4. Glue dipping solution, the glue solution includes water-based polyurethane and water; the glue solution includes 100 parts of water-based polyurethane and 3 parts of additives, add a little of the selected color slurry as needed, stir evenly, and put it into the slurry tank of the production line. After leaving the drying tunnel, dip the hand m...

Embodiment 2

[0037] 1. Preheating: Put the fabric glove core on the hand mold, enter the drying tunnel, set the temperature of the drying tunnel to 60 degrees Celsius, and preheat for 10 minutes.

[0038] 2. Soak the coagulant. The coagulant is a volatile organic acid; mix 94 parts of water and 6 parts of formic acid evenly and put it in the coagulant tank of the assembly line; until no liquid drips out.

[0039] 3. Baking: the hand mold enters the oven, the oven temperature is set at 60 degrees Celsius, and baked for 10 minutes.

[0040] 4. Glue dipping solution. The glue solution includes water-based polyurethane and water; the glue solution includes 70 parts of water-based polyurethane and 20 parts of styrene-butadiene latex. Add a little of the selected color slurry as needed, stir evenly, and put it into the slurry tank of the production line. After leaving the drying tunnel, dip the hand mold into the glue solution, and immerse half of the palm in the glue solution for 2 seconds. Af...

Embodiment 3

[0044] 1. Preheating: Put the fabric glove core on the hand mold, enter the drying tunnel, set the temperature of the drying tunnel to 60 degrees Celsius, and preheat for 10 minutes.

[0045] 2. Soak the coagulant. The coagulant is a volatile organic acid; mix 94 parts of water and 6 parts of formic acid evenly and put it in the coagulant tank of the assembly line; until no liquid drips out.

[0046] 3. Baking: the hand mold enters the oven, the oven temperature is set at 60 degrees Celsius, and baked for 10 minutes.

[0047] 4. Glue dipping solution, the glue solution includes water-based polyurethane and water; the glue solution includes 80 parts of water-based polyurethane and 20 parts of elastic acrylate emulsion, add a little of the selected color slurry as needed, stir evenly, and put it into the slurry tank of the production line . After leaving the drying tunnel, dip the hand mold into the glue solution, and immerse half of the palm in the glue solution for 2 seconds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com