Living microbial immobilization microsphere and preparation method and application thereof

A technology of microbial immobilization and microbial activity, applied in the field of environmental pollution microbial treatment, can solve the problems of low binding force between carriers and microorganisms, difficulty in exerting adsorption-accumulation, loss of microbial activity, etc. Highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

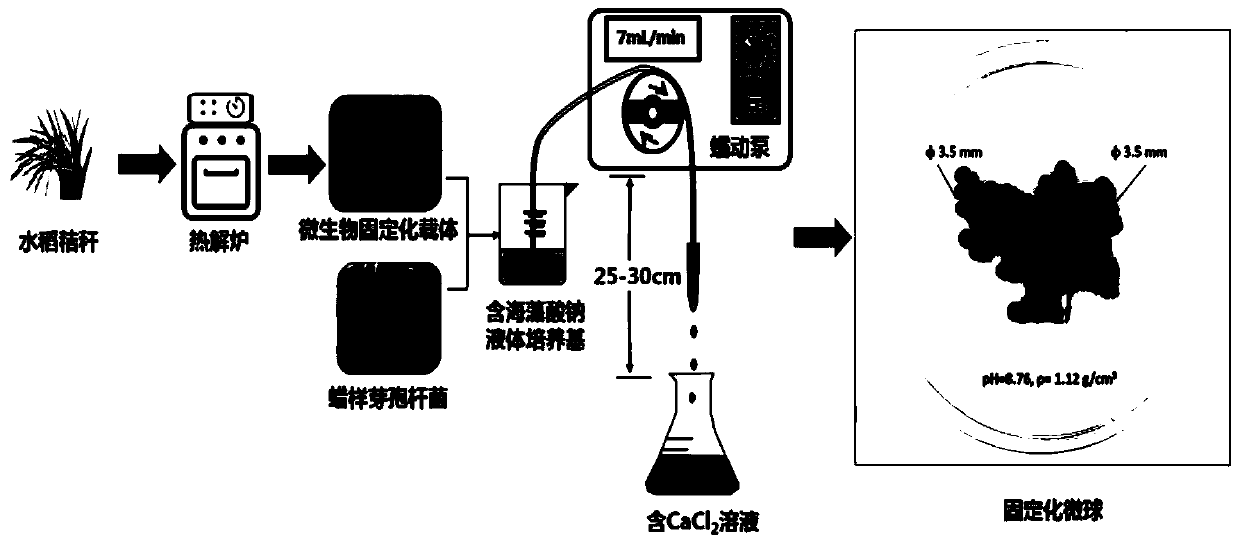

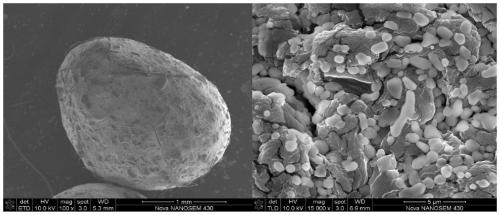

[0050] Example 1 Immobilized microsphere preparation process and material morphology and properties

[0051] see figure 1 , the preparation steps of the microsphere product are as follows:

[0052] In the first step, after natural air-drying, shredding and grinding, the rice straw was placed in a pyrolysis furnace that was fed with nitrogen gas for 20 minutes in advance, pyrolyzed at a temperature of 700 °C for 2 hours with limited oxygen, cooled to room temperature, ground and sieved to 100 mesh to obtain Microorganism immobilization carrier.

[0053] In the second step, inoculate 1 to 2 loops of Bacillus cereus RC-1 in beef extract peptone body liquid medium, and cultivate and activate at 30°C for 8 to 10 hours at 150 r / min (OD 600 =1.2~1.5), obtain cell suspension; get 5mL cell suspension and mix with 1.5g microbial immobilization carrier, shake culture 2h, make mixed slurry A; Mix slurry A to 100 mL to obtain mixed slurry B.

[0054] In the third step, the mixed slurry...

Embodiment 2

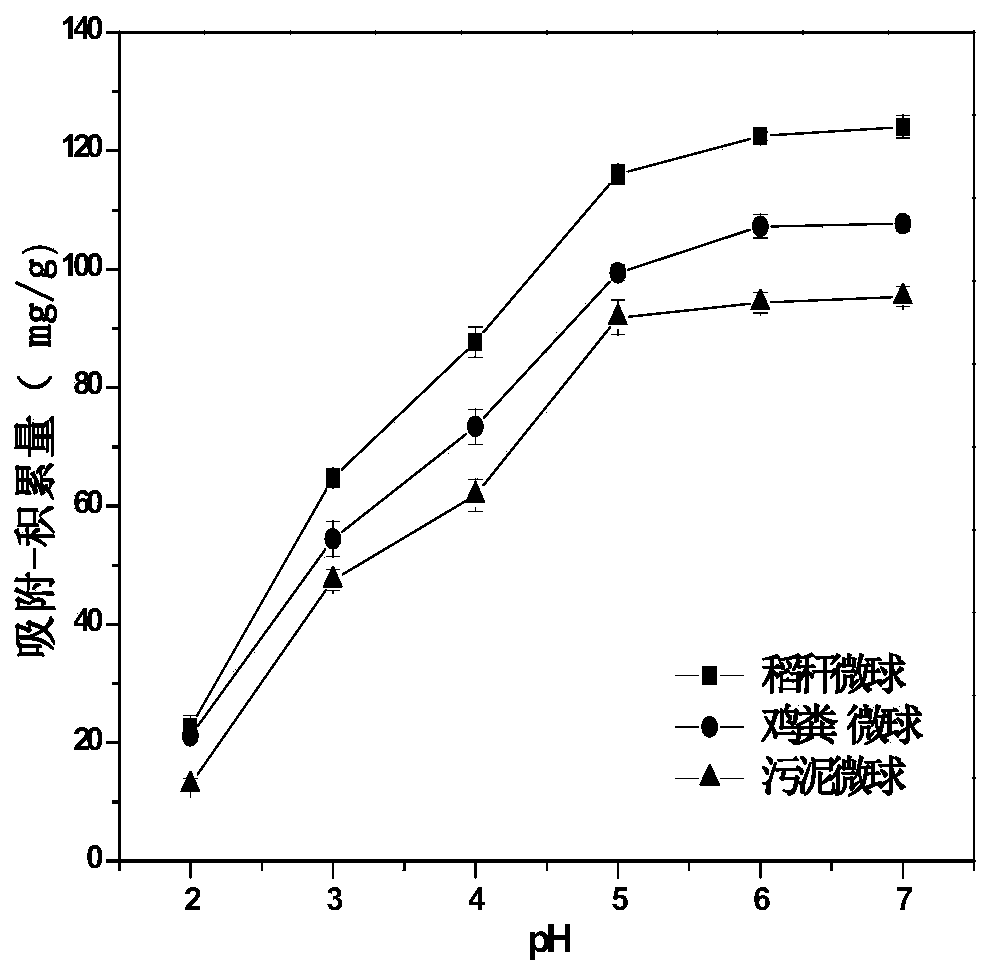

[0059] Example 2 Effect of pH on the adsorption-accumulation of immobilized microspheres

[0060] When the initial Cd 2+ At a concentration of 100 mg / L, for the microbial immobilization carriers (rice straw, chicken manure and sludge) prepared from three different raw materials, immobilized microspheres with a solid-liquid ratio of 0.2 g / L were prepared at different pH (2, 3, 4, 5, 6 and 7) in the beef extract peptone liquid medium (pH is 7.0 ± 0.2), after 24 hours of shaking culture at a shaking speed of 150r / min at room temperature, centrifuge the supernatant (10000rpm, 15min) to measure Cd 2+ concentration.

[0061] from image 3 It can be seen that as the initial pH ranges from 2 to 5, the adsorption-accumulation amounts of the three immobilized microspheres all increase rapidly, then gradually slow down, and finally reach equilibrium. When the initial pH is in the range of 5 to 7, the adsorption-accumulation amount of immobilized microspheres ranges from 91.84 to 124.0...

Embodiment 3

[0063] Example 3 Initial Cd 2+ Effects of concentration on the adsorption-accumulation of immobilized microspheres, the number of microorganisms and the activity of ATPase.

[0064] at different initial Cd 2+ Concentration (5, 10, 20, 50, 80, 100, 110, 120, 150, 180, 200, 210, 220, 250mg / L) in beef extract peptone liquid medium (pH is 7.0 ± 0.2), add solid Liquid ratio is 0.2g / L the living microorganism immobilized microsphere prepared in the embodiment 1, after 24h (150r / min) after constant velocity shaking culture under normal temperature, centrifugation gets supernatant (10000rpm, 15min) and measures Cd 2+ concentration. In addition, the isolated immobilized microspheres were placed in 20mL buffer solution (0.05mol / L Na 2 CO 3 and 0.02mol / L citric acid), shake culture for 1h, after the microspheres are completely dissolved, carry out microbial plate count and ATPase activity determination.

[0065] from Figure 4 a It can be seen that with the initial Cd 2+ With the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com