Integral loading acidifying machine

An integral, hydrolytic acidification technology, applied in the direction of solid waste removal, etc., can solve the problems of sewer pipe network blockage and aggravate sewage pollution, and achieve the effect of improved treatment efficiency, good operation effect and strong overall operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

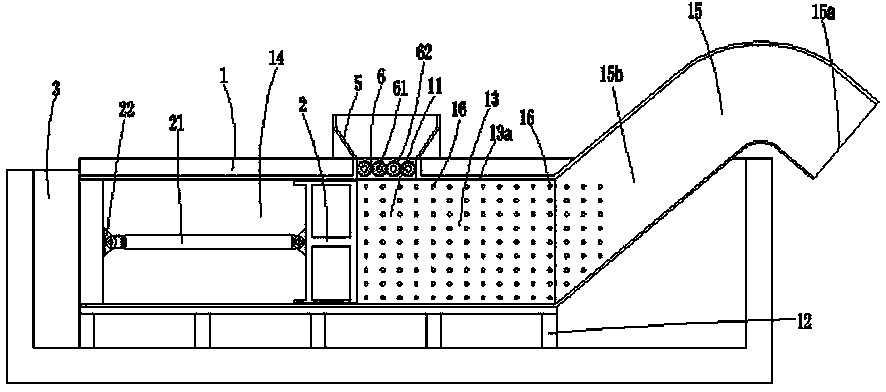

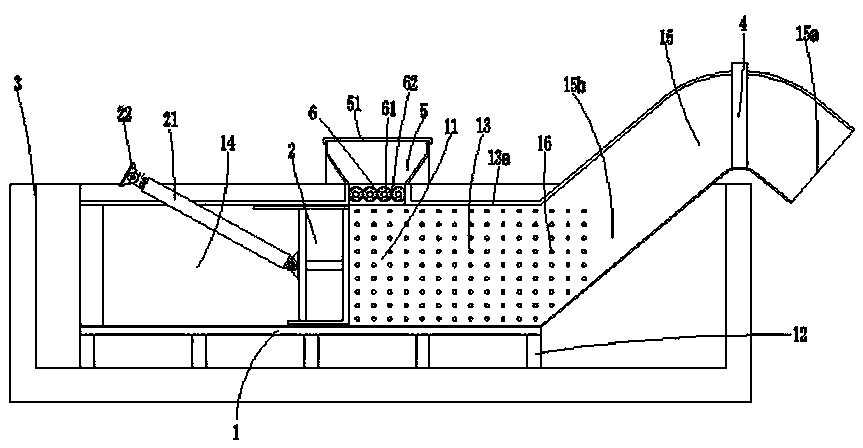

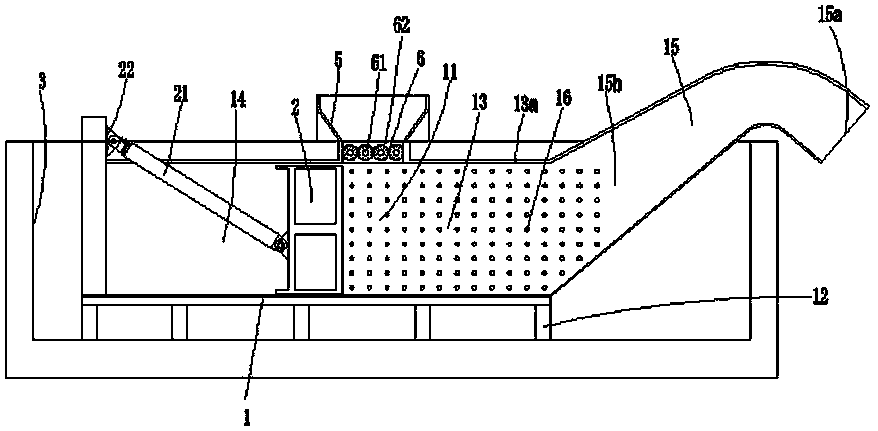

[0024] Such as Figure 1 to Figure 3 As shown, the icon numbers are as follows: body box 1, feed bin 11, unit support column 12, acidizing bin 13, upper sealing plate 13a, loading power bin 14, outlet bin 15, outlet 15a, inlet 15b, through hole 16 , Load head 2, push cylinder 21, cylinder base 22, hydrolysis acidification tank 3, opening and closing door 4, feed hopper 5, material cover body 51, bag breaking device 6, unit roll shaft 61, sawtooth body 62.

[0025] The embodiment of the present invention is an integral loading acidification machine. The loading acidification machine includes a main body box 1, and the main body box 1 is provided with a loading power bin 14, a feeding bin 11, an acidizing bin 13 and a feeding bin 15 in an integrated structure; The material bin 11 is located in the middle of the main body box 1, the loading powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com