Rapid decarbonization and coagulation integrated clarifying equipment

A decarbonization and coagulation technology, applied in the field of sedimentation treatment, large-scale water quality clarification, clarification, and sedimentation equipment, can solve the problems of low rising flow rate in the separation zone, small equipment output, and short reaction process, so as to increase the reflux ratio and equipment Large output and uniform water distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

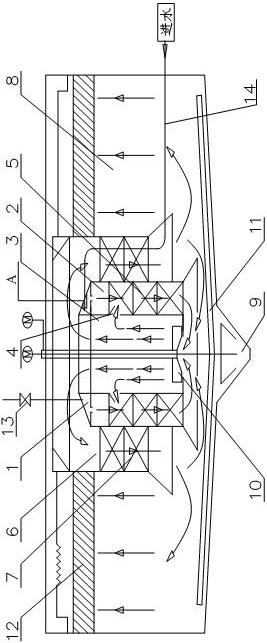

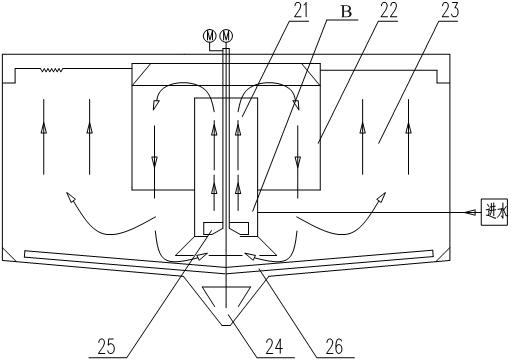

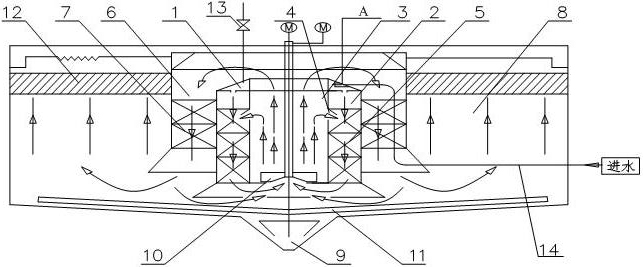

[0014] Embodiment one, see figure 1 . The rapid decarburization coagulation integrated clarification equipment in this embodiment includes: a closed small resistance water distribution ring 1, an internal reflux circulation reaction chamber 2, a mixing reaction chamber 3, a reflux port 4, an internal reflux circulation turbulence mixing device 5, and an external Backflow circulation reaction chamber 6, external backflow circulation turbulence mixing device 7, sedimentation area 8, mud storage bucket 9, lifting mixer 10, mud scraper 11, inclined pipe (slope plate) 12, exhaust valve 13.

[0015] Among them, the mixing reaction chamber 3, the internal reflux circulation reaction chamber 2, the external reflux circulation reaction chamber 6 and the precipitation area 8 are sequentially set together, and the closed small resistance water distribution ring 1 can ensure the uniform water distribution of the equipment. On the top of the reflux circulation reaction chamber 2, in order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com