Stationary type organic material fermentation machine and fermentation technology thereof

A stationary, fermenter technology, applied in the direction of organic fertilizer, organic fertilizer preparation, animal carcass fertilizer, etc., can solve the problems of difficult to achieve standardized large-scale production, inconsistent product quality, uncontrollable process, etc., to shorten the fermentation time. time, improve fermentation efficiency, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

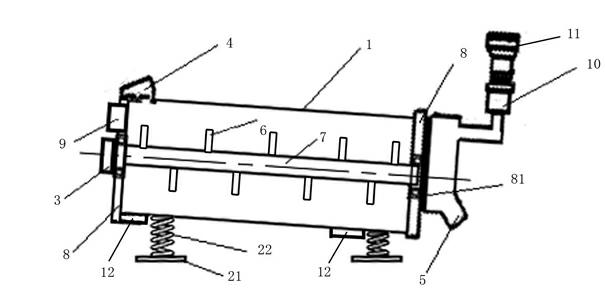

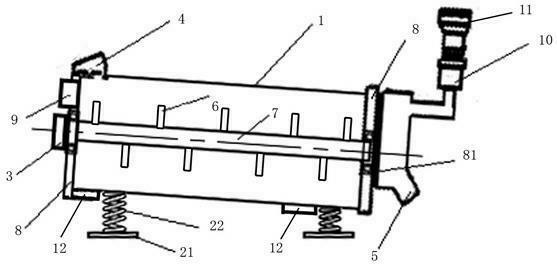

[0026] For a better understanding of the present invention, further description will be given below in conjunction with the accompanying drawings.

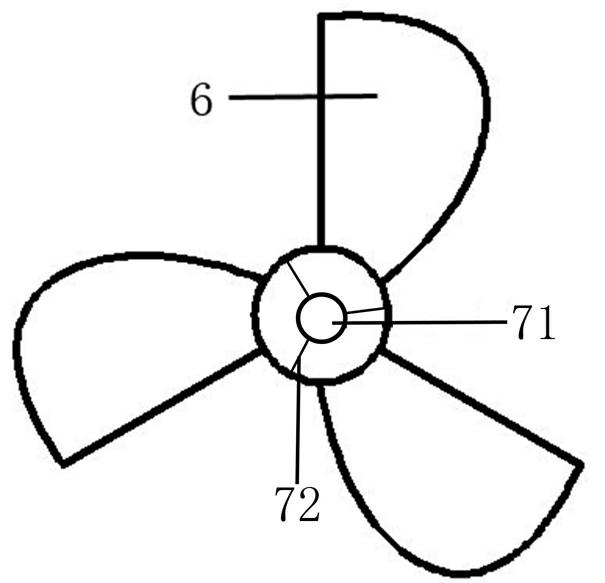

[0027] A fixed organic fertilizer fermentation machine, comprising a base, a fermentation cylinder 1, a motor 3, an electric control box, an air cleaner 11 and a microwave electromagnetic heater 12, the two ends of the fermentation cylinder 1 are fixedly erected on the base, The microwave electromagnetic heater 12 is located at the front and rear ends of the bottom of the outer wall of the fermentation cylinder. The motor 3 is electrically connected to the electric control box. The motor 3 is provided with a rotating shaft 7. The rotating shaft is a hollow pipe 71 provided with an air outlet 72. 7 runs through the middle of the fermentation cylinder 1, and several rows of blades 6 are extended on the rotating shaft 7. During the fermentation process, the motor 3 drives the rotating shaft 7 to rotate, so that the blades 6 fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com