Fiber-reinforced epoxy asphalt material and preparation method thereof

An epoxy bitumen material and fiber-reinforced technology, which can be used in building thermal insulation materials, on-site coagulation pavement, building components, etc., can solve problems such as material damage and material toughness reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0040] Example 2: Accurately weigh 30g of asphalt and add it to a stirred tank at normal pressure and heat it to 120°C to melt it, weigh 5g of polypropylene fiber (Shanghai Xianghu Industrial Co., Ltd., the same below), 8g of methyltetrahydrophthalic anhydride, 15g mixture of adipic acid and sebacic acid, 5g mixture of polysebacic acid and isobutadiene dioic anhydride, add them all at 120°C to the normal pressure stirring tank at one time, stir for 1 hour until the viscosity of the system is almost uniform, then add 20g epoxy The resin was mixed evenly, and the properties of the fiber-reinforced epoxy asphalt material prepared were shown in Table 1.

Embodiment 3

[0041] Embodiment 3: Accurately weigh 30g of asphalt and add it to an atmospheric pressure stirred tank and heat it to 120°C to melt it, weigh 5g of polyester fiber (Binzhou Jinlong Plastic Co., Ltd., the same below), 8g of methyltetrahydrophthalic anhydride, 15g mixture of adipic acid and sebacic acid, 5g mixture of polysebacic acid and isobutadiene dioic anhydride, add them all at 120°C to the normal pressure stirring tank at one time, stir for 1 hour until the viscosity of the system is almost uniform, then add 20g epoxy The resin was mixed evenly, and the properties of the fiber-reinforced epoxy asphalt material prepared were shown in Table 1. .

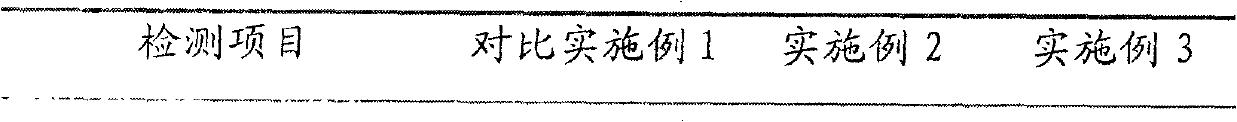

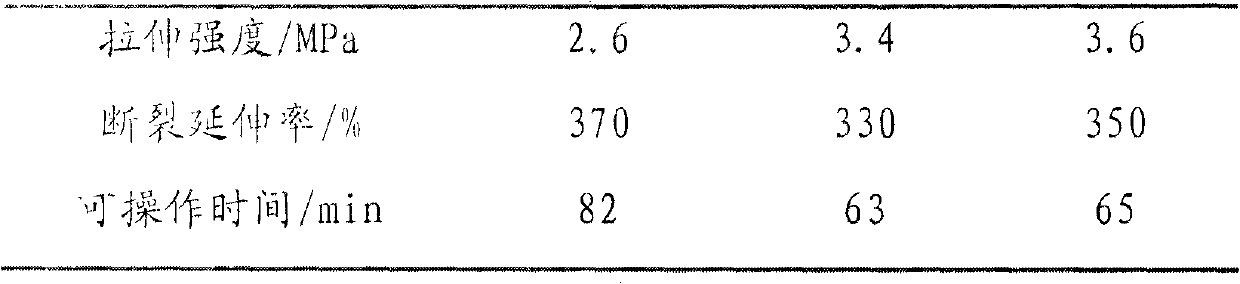

[0042] Table 1 Performance table of epoxy asphalt

[0043]

[0044]

Embodiment 5

[0047] Example 5: Accurately weigh 300g of asphalt and add it to an atmospheric pressure stirred tank and heat it to 120°C to melt it, weigh 50g of polypropylene fiber, 80g of methyltetrahydrophthalic anhydride, 150g of adipic acid and sebacic acid, Add 50g of the mixture of polysebacic acid and isobutylene dioic anhydride to a 120°C normal-pressure stirred tank at one time, stir for 1 hour until the viscosity of the system is almost uniform, then add 200g of epoxy resin and mix evenly to prepare a fiber-reinforced ring. Oxygen asphalt components.

[0048] Accurately weigh 10Kg of AC-10 aggregate that has been placed in an oven at 150°C for more than 4 hours at a constant temperature, add it to a stirring pot at 150°C, and add the prepared epoxy asphalt component according to the oil-stone ratio of 7.0%, continue stirring for 90s, press the test It is required to prepare test pieces and keep the pieces in an oven at 150°C for more than 6h. The properties of the prepared fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com